Energy-saving process for separation of ethyl acetate-ethanol by pressure swing rectification with side draw

A technology for ethyl acetate and sideline extraction, which is applied in the field of rectification and purification, can solve the problems of high separation energy consumption, complicated operation, difficult separation, etc., and achieves the effects of reducing energy consumption and equipment investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

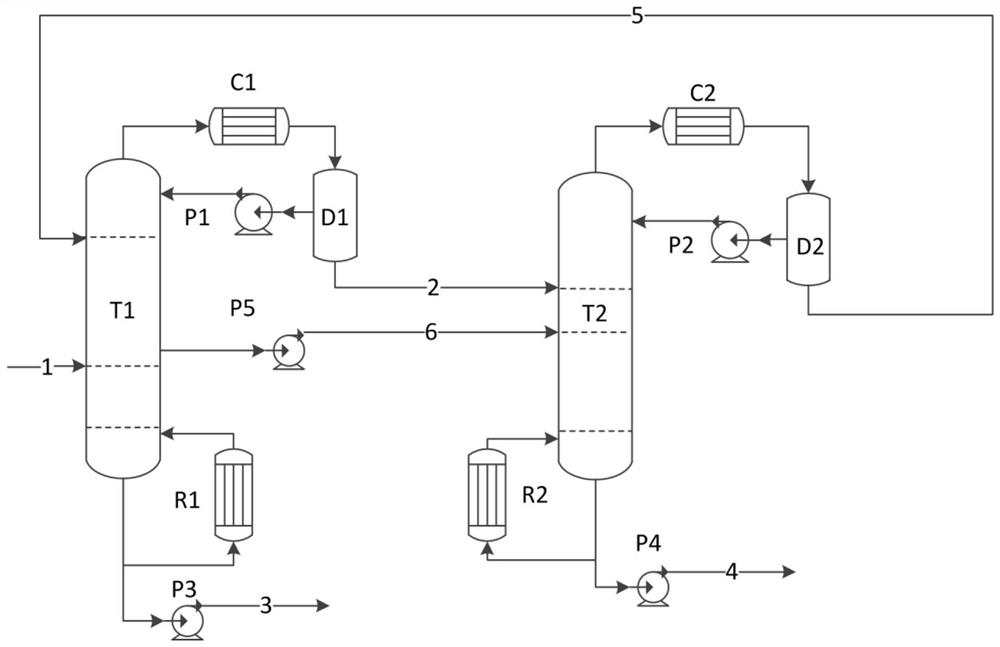

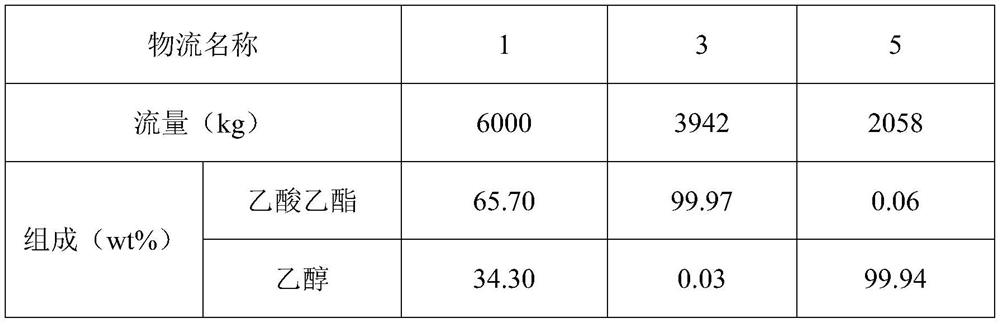

[0028] Attached figure 1 In the process flow diagram shown, the feed flow rate is 6000kg / h, the feed temperature is 32°C, and the feed composition is 65.7% (mass fraction) of ethyl acetate and 34.3% (mass fraction) of ethanol. The theoretical plate number of the high-pressure distillation column is 45, the pressure is 6.0atm (absolute pressure), the feed is from the 27th plate, the circulating feed position is the 35th plate, the side line extraction position is the 22nd plate, and the reflux The ratio is 1.6; the number of theoretical plates of the low-pressure rectification tower is 25, the pressure is 0.5 atm (absolute pressure), the feed is fed from the 15th tray, the feed position of the side line extraction is the 9th tray, and the reflux ratio is 0.9. After separation, the ethyl acetate product concentration is 99.97%, and the recovery rate is 99.95%, and the ethanol product concentration is 99.94%, and the recovery rate is 99.91%.

[0029] Table 1 Distillation column ...

Embodiment 2

[0038] Attached figure 1 In the process flow diagram shown, the feed flow rate is 6700kg / h, the feed temperature is 32°C, and the feed composition is 70% (mass fraction) of ethyl acetate and 30% (mass fraction) of ethanol. The theoretical plate number of the high-pressure distillation column is 50, the pressure is 6.5atm (absolute pressure), the feed is from the 29th plate, the circulating feed position is the 37th plate, the side line extraction position is the 24th plate, and the reflux The ratio is 1.7; the number of theoretical plates of the low-pressure rectification column is 28, the pressure is 0.8 atm (absolute pressure), the feed is from the 17th plate, the feed position of the side line is the 10th plate, and the reflux ratio is 1.0. After separation, the ethyl acetate product concentration is 99.96%, and the recovery rate is 99.92%, and the ethanol product concentration is 99.97%, and the recovery rate is 99.94%.

[0039] Table 4 Distillation column information tab...

Embodiment 3

[0047] Attached figure 1In the process flow diagram shown, the feed flow rate is 7000kg / h, the feed temperature is 32°C, and the feed composition is 50% (mass fraction) of ethyl acetate and 50% (mass fraction) of ethanol. The theoretical plate number of the high-pressure rectification tower is 55, the pressure is 8.0atm (absolute pressure), the feed is from the 31st plate, the circulating feed position is the 40th plate, the side line extraction position is the 26th plate, and the reflux The ratio is 1.8; the number of theoretical plates of the low-pressure rectification tower is 30, the pressure is 1.0atm (absolute pressure), the feed is fed from the 18th tray, the feed position of the side line is the 12th tray, and the reflux ratio is 1.2. After separation, the ethyl acetate product concentration is 99.98%, and the recovery rate is 99.95%, and the ethanol product concentration is 99.98%, and the recovery rate is 99.94%.

[0048] Table 7 Distillation column information tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com