An energy-saving process for separating methanol, isopropanol and water by heat pump extraction and rectification

A technology of extractive distillation and isopropanol, which is applied in the direction of extractive distillation, liquid solution solvent extraction, water, etc., and can solve the problem of difficult separation of methanol-isopropanol-water mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

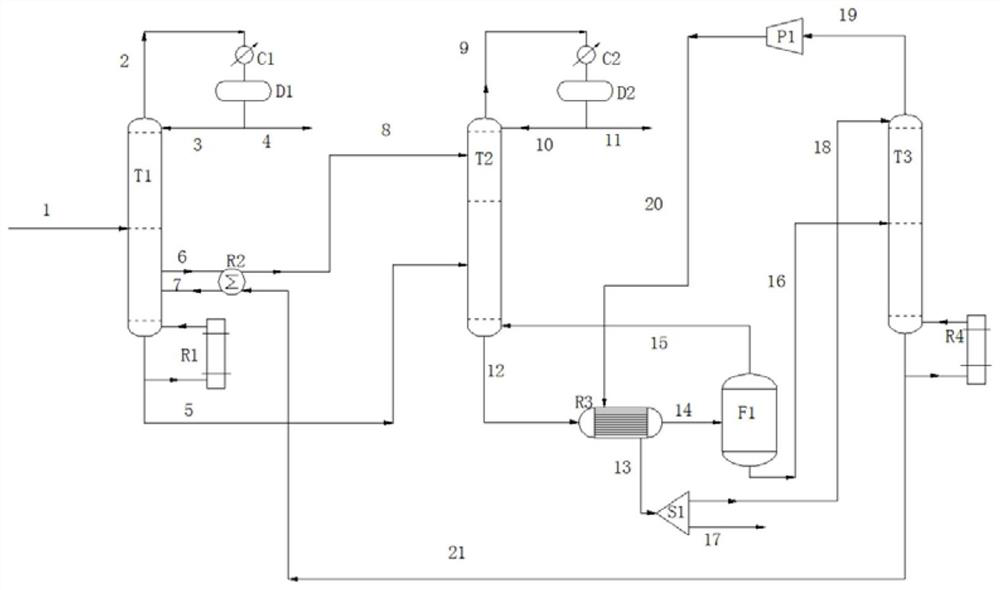

Image

Examples

Embodiment 1

[0032] Take 2000kg / h of 20wt% methanol and 30wt% isopropanol as an example:

[0033] The number of plates in the methanol removal tower (T1) is 60, and the mixed material enters the methanol removal tower (T1) from the 25th tray, and the stream 6 passes through the bottom stream of the intermediate reboiler (R2) and the dehydration tower (T3) After heat exchange, it is refluxed from the 50th tray to the methanol removal tower (T1). The column bottom stream 5 of the demethanolization tower (T1) enters the deisopropanol tower (T2) by the 30th block tower, and the deisopropanol tower (T2) has 42 trays in total, and the extractant ethylene glycol is fed by the 2nd plate Enter the removal of isopropanol tower (T2), the flow rate of extractant ethylene glycol is 2000kg / h. The operating pressure of the dehydration tower is normal pressure, and the dehydration tower (T3) has 22 plates in total. The mixed solution of water and extractant enters the dehydration tower (T3) from the 12t...

Embodiment 2

[0035] Take the 1800kg / h mixed solution of 17wt% methanol and 33wt% isopropanol as an example:

[0036]The number of plates in the methanol removal tower (T1) is 58, the mixed material enters the methanol removal tower (T1) from the 24th tray, and the stream 6 passes through the bottom stream of the intermediate reboiler (R2) and the dehydration tower (T3) After heat exchange, it is refluxed from the 51st tray to the methanol removal tower (T1). The column bottom stream 5 of the methanol removal tower (T1) enters the removal of isopropanol tower (T2) from the 31st block tower, and the removal of isopropanol tower (T2) has 41 trays in total, and the extractant ethylene glycol is fed by the 4th block Enter the isopropanol removal tower (T2), and the flow rate of the extractant ethylene glycol is 1850kg / h. The operating pressure of the dehydration tower is normal pressure, and the dehydration tower (T3) has a total of 23 plates. The mixed solution of water and extractant enters...

Embodiment 3

[0038] Take the 2100kg / h mixed solution of 22wt% methanol and 32wt% isopropanol as an example:

[0039] The number of plates in the methanol removal tower (T1) is 61, and the mixed material enters the methanol removal tower (T1) from the 26th tray, and the stream 6 passes through the bottom stream of the intermediate reboiler (R2) and the dehydration tower (T3) After heat exchange, it is refluxed from the 49th tray to the demethanolization tower (T1). The column bottom stream 5 of the methanol removal tower (T1) enters the removal of isopropanol tower (T2) from the 28th block tower, and the removal of isopropanol tower (T2) has a total of 42 trays, and the extractant ethylene glycol is fed from the 3rd block Enter the removal of isopropanol tower (T2), the flow rate of the extractant ethylene glycol is 2050kg / h. The operating pressure of the dehydration tower is normal pressure, and the dehydration tower (T3) has a total of 20 plates. The mixed solution of water and extracta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com