Energy-saving process for pressure change separation of ethylenediamine-water through side line extraction and complete heat integration

A side-line extraction and ethylenediamine technology, which is applied in the purification/separation of amino compounds, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of difficulty in ethylenediamine-water separation, large equipment investment, and high energy consumption for separation , to achieve the effect of reducing equipment operating costs, reducing energy consumption and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

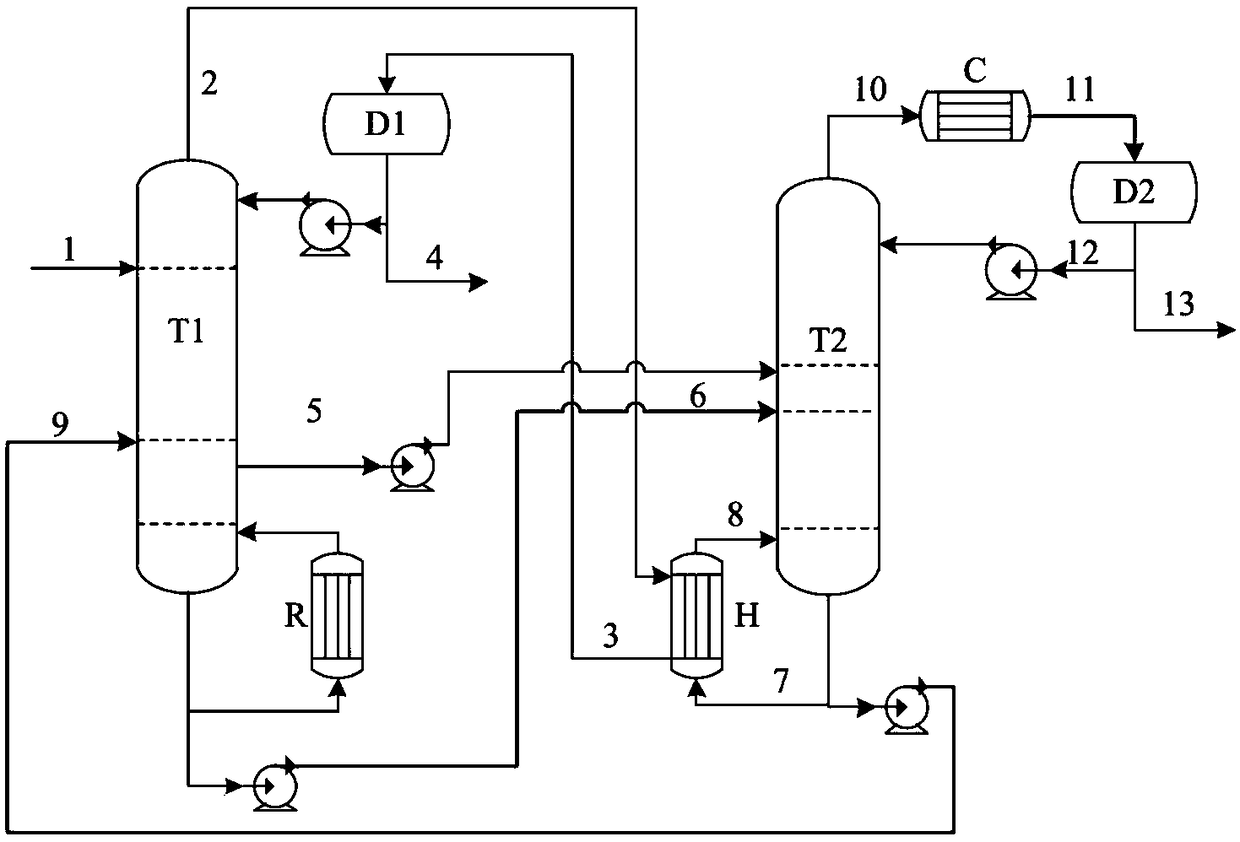

[0029] Attached figure 1 In the process flow diagram shown, the feed flow rate is 1000kg / h, the feed temperature is 47°C, and the feed composition is 60% (mass fraction) of ethylenediamine and 40% (mass fraction) of water. The theoretical plate number of the high-pressure distillation column is 60, the pressure is 2.0atm (absolute pressure), the feed is fed from the 6th plate, the circulating feeding position is the 14th plate, the side line extraction position is the 29th plate, and the reflux The ratio is 5.8; the number of theoretical plates of the low-pressure rectification tower is 22, the pressure is 0.1atm (absolute pressure), the feed is fed from the 11th tray, the feed position of the side line is the 8th tray, and the reflux ratio is 3. After separation, the ethylenediamine product has a purity of 99.95% and a recovery rate of 99.85%, and the aquatic product has a purity of 99.95% and a recovery rate of 99.85%.

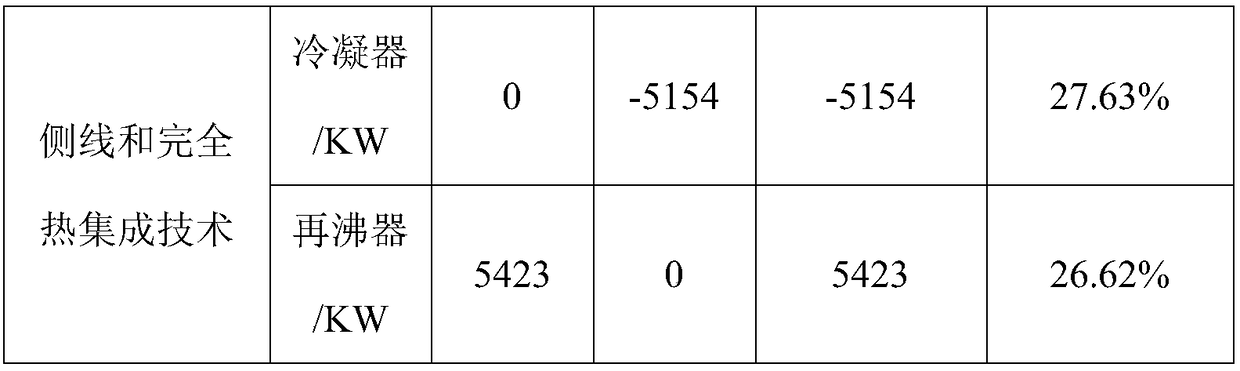

[0030] The energy consumption comparison data of comp...

Embodiment 2

[0034] Attached figure 1 In the process flow diagram shown, the feed flow rate is 1200kg / h, the feed temperature is 47°C, and the feed composition is 65% (mass fraction) of ethylenediamine and 35% (mass fraction) of water. The theoretical plate number of the high-pressure rectification tower is 65, the pressure is 3.0atm (absolute pressure), the feed is fed from the 10th plate, the circulating feeding position is the 16th plate, the side line extraction position is the 29th plate, and the reflux The ratio is 6.0; the number of theoretical plates of the low-pressure rectification tower is 23, the pressure is 0.3atm (absolute pressure), the feed is fed from the 13th tray, the feeding position of the side line is the 9th tray, and the reflux ratio is 4. After separation, the ethylenediamine product has a purity of 99.96% and a recovery rate of 99.86%, and the aquatic product has a purity of 99.96% and a recovery rate of 99.86%.

[0035] The energy consumption comparison data of ...

Embodiment 3

[0038] Attached figure 1In the process flow diagram shown, the feed flow rate is 1500kg / h, the feed temperature is 47°C, and the feed composition is 70% (mass fraction) of ethylenediamine and 30% (mass fraction) of water. The theoretical plate number of the high-pressure distillation column is 68, the pressure is 4.0atm (absolute pressure), the feed is fed from the 15th plate, the circulating feeding position is the 18th plate, the side line extraction position is the 35th plate, and the reflux The ratio is 6.3; the number of theoretical plates of the low-pressure rectification column is 25, the pressure is 0.5 atm (absolute pressure), the feed is fed from the 15th plate, the feed position of the side line is the 10th plate, and the reflux ratio is 5. After separation, the ethylenediamine product has a purity of 99.97% and a recovery rate of 99.87%, and the aquatic product has a purity of 99.97% and a recovery rate of 99.87%.

[0039] The energy consumption comparison data of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com