A method and device for separating a mixture of toluene and ethanol

A mixture, ethanol technology, applied in chemical instruments and methods, preparation of organic compounds, extraction and purification/separation, etc., can solve the problems of difficult separation, large investment and process energy consumption, high energy consumption, etc., and achieve the goal of improving separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 A kind of method for separating toluene and ethanol mixture, comprises the following steps:

[0046] A. Extract the ethanol in the toluene with saline water, and then use ordinary rectification to refine the toluene;

[0047] B, the trace toluene in the mixture containing salt, water, ethanol, trace toluene in the xylene extraction step A, the mixture containing xylene, toluene, trace ethanol goes to step A;

[0048] C, extract the ethanol in the salt, water and ethanol mixture with xylene in step B, then separate xylene and ethanol with ordinary rectification, remove the water and salt mixture of ethanol and return to step A for recycling;

[0049] D. The xylene obtained by refining toluene and ethanol is reused.

[0050] Described salt comprises: lithium sulfate, sodium sulfate, potassium sulfate, ferrous sulfate, iron thiocyanate, sodium thiocyanide, potassium thiocyanide, sodium acetate, potassium acetate, sodium carbonate, potassium carbonate, sodium ...

Embodiment 2

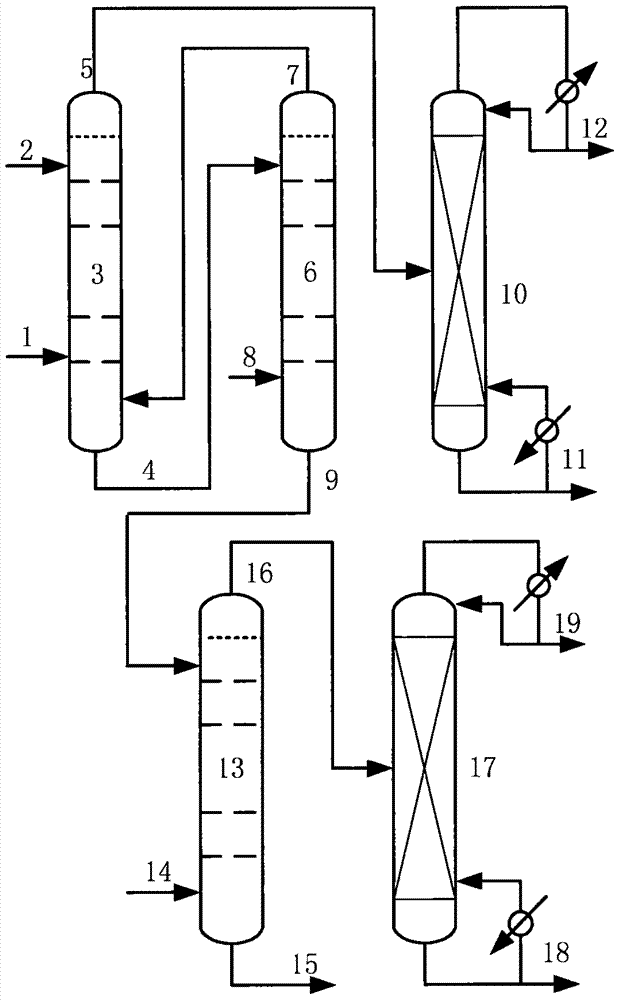

[0051] Embodiment 2 The main equipment that realizes the method for separating toluene and ethanol mixture includes:

[0052] Ethanol extraction tower (3), toluene extraction tower (6), toluene refining tower (9), ethanol stripping tower (13), ethanol refining tower (17).

[0053] Process flow:

[0054] The ethanol extraction tower (3) is an extraction tower for extracting and separating ethanol. Toluene and ethanol mixture (1) enters the middle and lower part of the ethanol extraction tower (3), the water that adds salt enters the ethanol extraction tower (3) top, the mixture (7 ) into the lower part of the ethanol extraction tower (3), obtain the mixture (5) containing non-polar solvent A and toluene from the ethanol extraction tower (3) tower top, and obtain the mixture (5) containing ethanol, water, salt and toluene in the ethanol extraction tower (3) tower still Mixture with traces of toluene (4); usable salts include: lithium sulfate, sodium sulfate, potassium sulfate,...

experiment example 1

[0061] Experimental Example 1: A mixture containing 70% toluene and 30% ethanol was extracted with an aqueous solution containing 4% sodium sulfate. After one extraction, the water layer contained 23.72% ethanol, 3.12% toluene, and 73.16% water, and the organic layer contained 98.71% toluene , containing 1.27% ethanol and 0.02% water; after the second extraction, the organic layer contained 99.41% toluene, 0.56% ethanol, and 0.01% water; after three extractions, the organic layer contained 99.95% toluene, 0.03% ethanol, and 0.02% water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com