Heat-conductive rubber material for drilling tools and preparation method thereof

A heat-conducting rubber and drilling tool technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve problems such as aging and sealing failure, and achieve the effects of improving temperature resistance, increasing thermal conductivity, and promoting uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

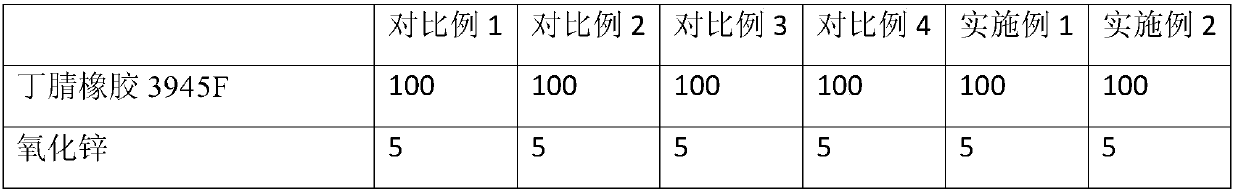

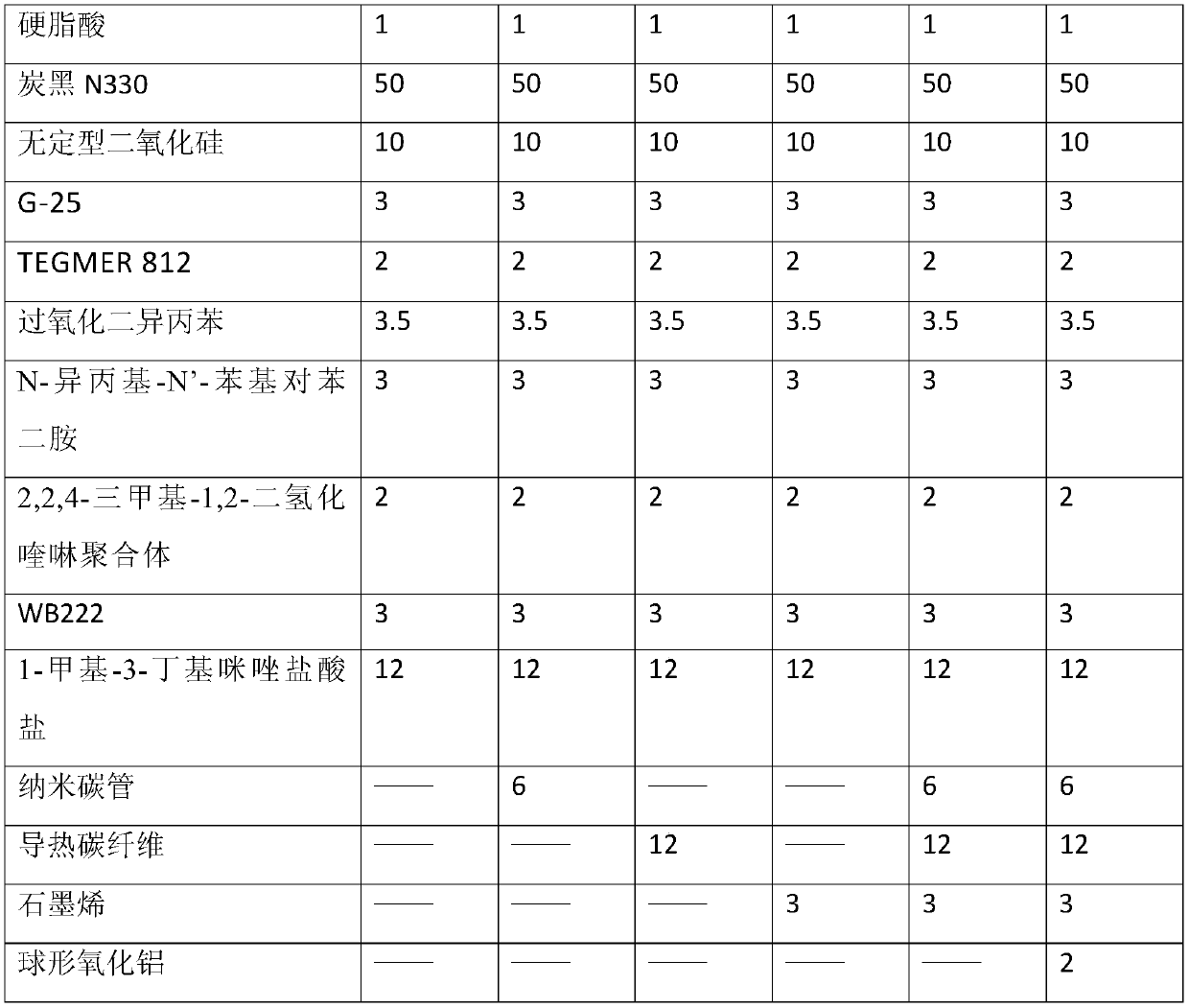

[0031] The mass ratios of the raw materials of Examples 1-2 of the present invention and Comparative Examples 1-4 are shown in Table 1, and all adopt nitrile rubber material as the main material, wherein Comparative Example 1 does not add heat-conducting material, and Comparative Example 2 is the same as Comparative Example 1. Based on the addition of carbon nanotubes; comparative example 3 added heat-conducting carbon fibers on the basis of comparative example 1; comparative example 4 added graphene on the basis of comparative example 1; embodiment 1 is based on comparative example 1 Carbon nanotubes, thermally conductive carbon fibers, and graphene are added; embodiment 2 adds spherical alumina on the basis of embodiment 1.

[0032] Table 1

[0033]

[0034]

[0035] The pretreatment process of the heat-conducting material in the above Examples 1-2 and Comparative Examples 2-4 is carried out as follows: add 5 parts of amorphous silicon dioxide to the ionic liquid at a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com