Extraction method of grease in quinoa bran and application of grease in food

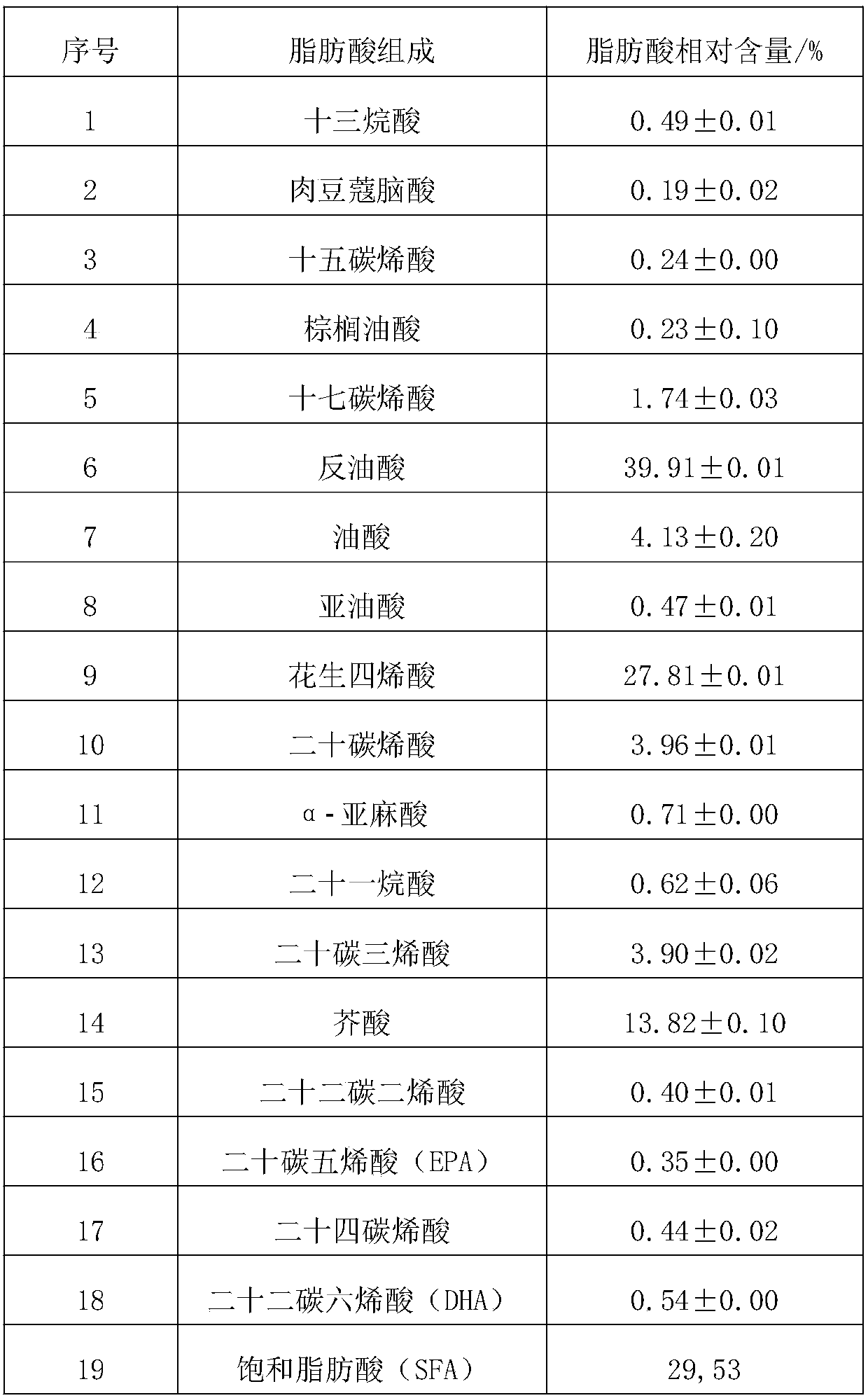

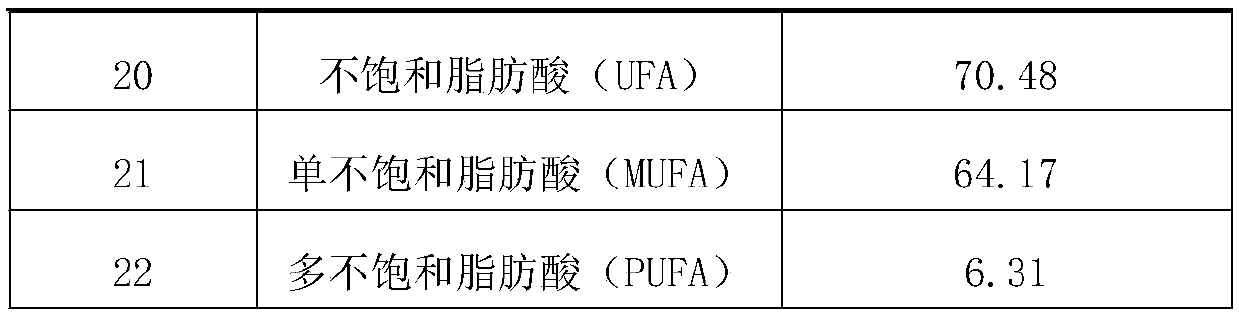

An extraction method and technology of quinoa bran, applied in the application, edible oil/fat, fat oil/fat production, etc., to achieve the effects of improving intelligence, reducing blood viscosity, and increasing blood vessel elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for extracting oil from quinoa bran, comprising the steps of:

[0024] (1) Sample treatment: Weigh the pulverized and dried quinoa bran powder to remove impurities and sterilize at high temperature;

[0025] (2) n-hexane and quinoa bran powder are mixed in a certain proportion, and ultrasonically extracted;

[0026] (3) adopt centrifuge centrifugal separation after extraction finishes;

[0027] (4) Rotary evaporation of n-hexane to obtain oil extracted from quinoa bran.

[0028] The condition of high temperature sterilization in the step (1) is 121° C. for 30 s, and the particle size of the quinoa bran powder in the step (1) is 50 mesh. The ratio of the amount (ml) of n-hexane to the mass (g) of quinoa bran powder in the step (2) is 5:1, the ultrasonic extraction temperature is 10° C., and the extraction time is 1 hour. In the step (3), the centrifuge parameter is 5000r / min, the centrifugation temperature is 10°C, and the centrifugation time is 10min. The c...

Embodiment 2

[0036] A method for extracting oil from quinoa bran, comprising the steps of:

[0037] (1) Sample treatment: Weigh the pulverized and dried quinoa bran powder to remove impurities and sterilize at high temperature;

[0038] (2) n-hexane and quinoa bran powder are mixed in a certain proportion, and ultrasonically extracted;

[0039] (3) adopt centrifuge centrifugal separation after extraction finishes;

[0040] (4) Rotary evaporation of n-hexane to obtain oil extracted from quinoa bran.

[0041] The condition of high temperature sterilization in the step (1) is 121° C. for 30 s, and the particle size of the quinoa bran powder in the step (1) is 60 mesh. The ratio of the amount (ml) of n-hexane to the mass (g) of quinoa bran powder in the step (2) is 20:1, the ultrasonic extraction temperature is 30° C., and the extraction time is 2 hours. In the step (3), the centrifuge parameter is 10000r / min, the centrifugation temperature is 30°C, and the centrifugation time is 60min. Th...

Embodiment 3

[0046] A method for extracting oil from quinoa bran, comprising the steps of:

[0047] (1) Sample treatment: Weigh the pulverized and dried quinoa bran powder to remove impurities and sterilize at high temperature;

[0048] (2) n-hexane and quinoa bran powder are mixed in a certain proportion, and ultrasonically extracted;

[0049] (3) adopt centrifuge centrifugal separation after extraction finishes;

[0050] (4) Rotary evaporation of n-hexane to obtain oil extracted from quinoa bran.

[0051] The high temperature sterilization condition in the step (1) is 121° C. for 30 s, and the particle size of the quinoa bran powder in the step (1) is 55 mesh. The ratio of the amount (ml) of n-hexane to the mass (g) of quinoa bran powder in the step (2) is 12:1, the ultrasonic extraction temperature is 20° C., and the extraction time is 1.5 hours. In the step (3), the centrifuge parameter is 7000r / min, the centrifugation temperature is 20°C, and the centrifugation time is 35min. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com