Film coating machine flattening roller layout structure and film coating machine using the same

A layout structure and flattening roller technology, which is applied in the field of coating machine flattening roller layout structure, can solve problems such as inconsistency and difficulty in adjusting the direction of the flattening rollers, achieve thick coating thickness, meet coating thickness requirements, and be easy to adjust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

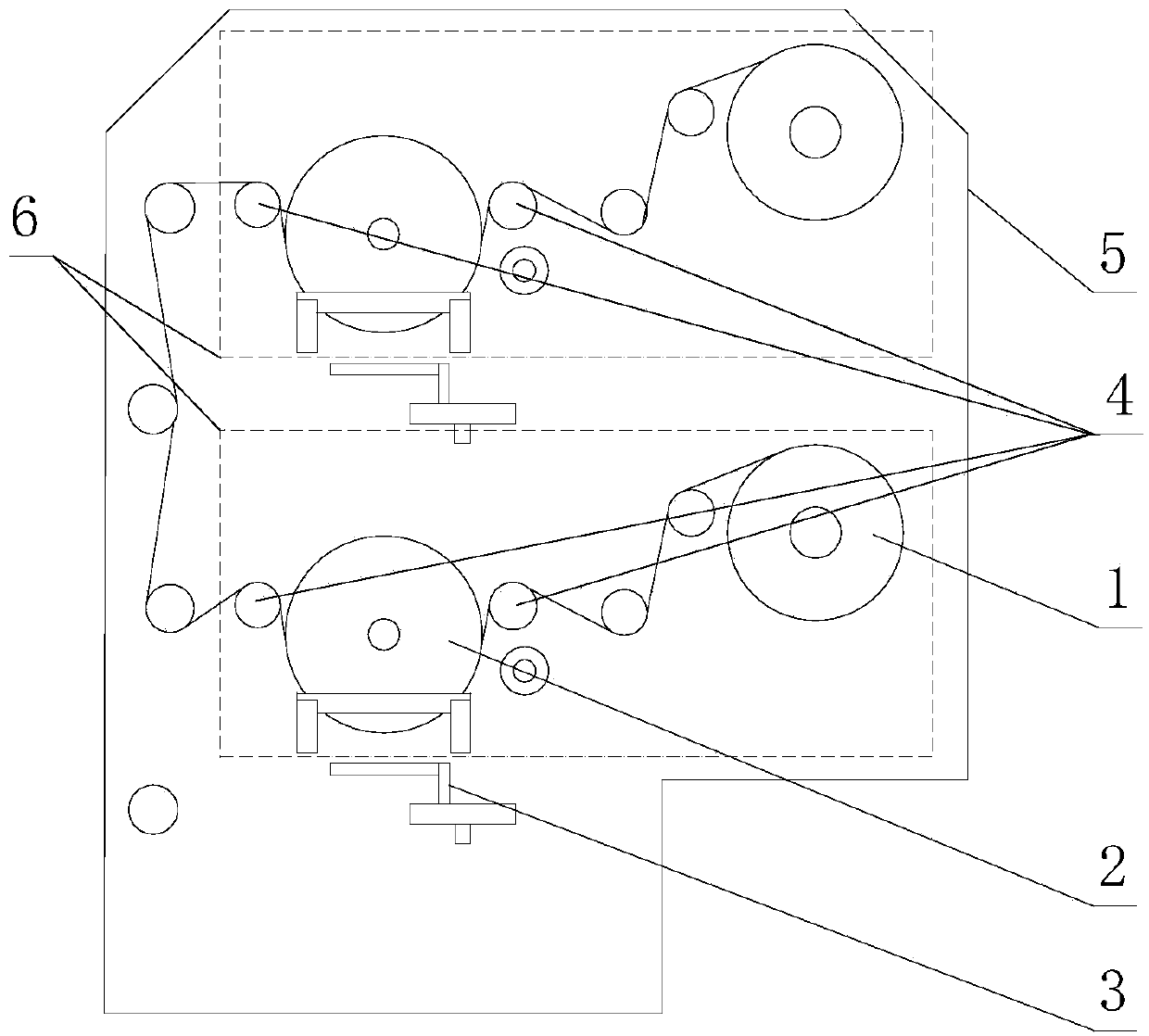

[0044] A coating machine flattening roller layout structure, including a main roller 2; also includes at least two flattening rollers 4, the flattening rollers 4 are respectively located on both sides of the input surface and the output surface of the main roller 2; 2. The flattening rollers 4 on both sides are different from the active surfaces of the main roller 2 and the strip.

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the flattening rollers 4 located on both sides of the main roller 2 are symmetrical about the straight axis where one diameter of the main roller 2 is located.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that the axes of the flattening rollers 4 located on both sides of the main roller 2 are located on the same horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com