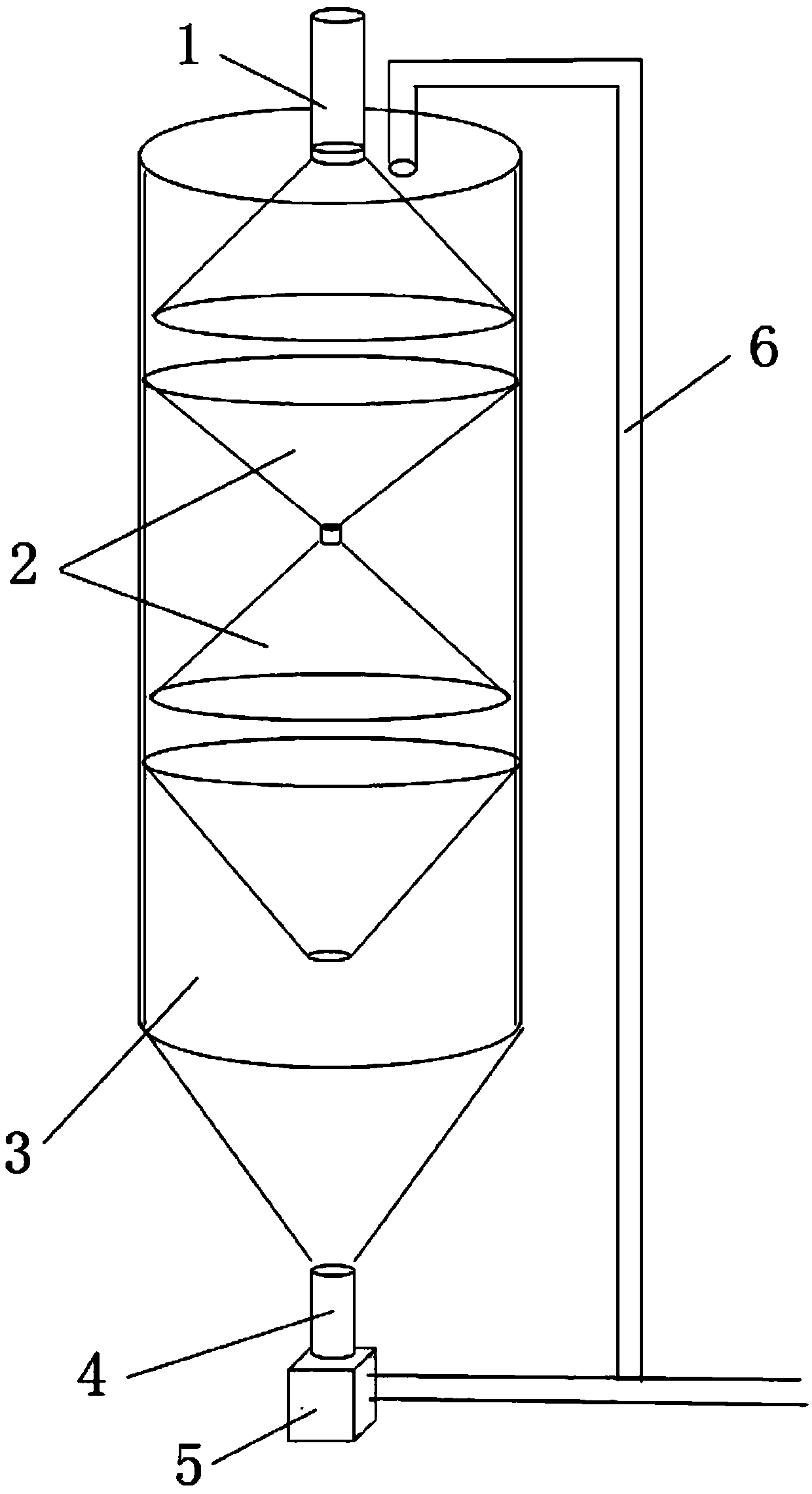

Defoaming device and defoaming method for aramid fiber III spinning solution

A fiber spinning and spinning liquid technology, which is applied in spinning solution filtration, fiber treatment, filament forming treatment, etc., can solve the problems of low defoaming efficiency, low production capacity, low production efficiency, etc., and achieve the reduction of liquid Effects of thickness, guaranteed stability, and accelerated efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare 500 kg of aramid fiber spinning solution with a dynamic viscosity of 1,000,000 Pa.s; turn on the vacuum system of the defoaming tower, and adjust the vacuum degree to -80kpa; turn on the thermostatic jacket device, and set the temperature to 25°C; Send into the umbrella plate type defoaming device of the present invention; Open delivery pump after 30min; Sampling aramid fiber III fiber spinning liquid; All the other enter spinning process and carry out single-station 1100dtex model spinning effect verification;

[0032] vs. 2m 3 See Table 1 for the monitoring result data of storage tank static defoaming spinning solution:

[0033] Table 1

[0034]

Embodiment 2

[0036] Prepare 500 kg of aramid fiber III fiber spinning solution with a dynamic viscosity of 1,250,000 Pa.s; turn on the vacuum system of the defoaming tower, and adjust the vacuum degree to -85kpa; turn on the thermostatic jacket device, and set the temperature at 28°C; Send into the umbrella plate type defoaming device of the present invention; Open delivery pump after 60min; Sampling aramid fiber III fiber spinning solution; All the other enter spinning procedure to carry out single-station 1100dtex model spinning effect verification;

[0037] vs. 2m 3 See Table 2 for the monitoring result data of storage tank static defoaming spinning solution:

[0038] Table 2

[0039]

Embodiment 3

[0041] Prepare 500kg of aramid fiber III fiber spinning solution with a dynamic viscosity of 1500000Pa.s; turn on the vacuum system of the defoaming tower and adjust the vacuum degree to -90kpa; turn on the thermostatic jacket device and set the temperature to 30°C; Send into the umbrella plate type defoaming device of the present invention; Open delivery pump after 60min; Sampling aramid fiber III fiber spinning solution; All the other enter spinning procedure to carry out single-station 1100dtex model spinning effect verification;

[0042] vs. 2m 3 See Table 3 for the monitoring result data of storage tank static defoaming spinning solution:

[0043] table 3

[0044]

[0045] It can be seen from the data in Tables 1 to 3 that the aramid III fiber spinning liquid multi-stage defoaming tower device provided by the embodiment of the present invention has faster defoaming, faster spinning liquid turnover, and lower equipment cost than the static decompression degassin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com