Liquid-spraying spinning device

A spinning device and liquid jet technology, applied in the field of spinning, can solve the problems of inconsistent spinning performance, inhomogeneous properties, and influence of volatilization, and achieve the effects of avoiding physical harm, avoiding different spinning thicknesses, and being easy to observe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

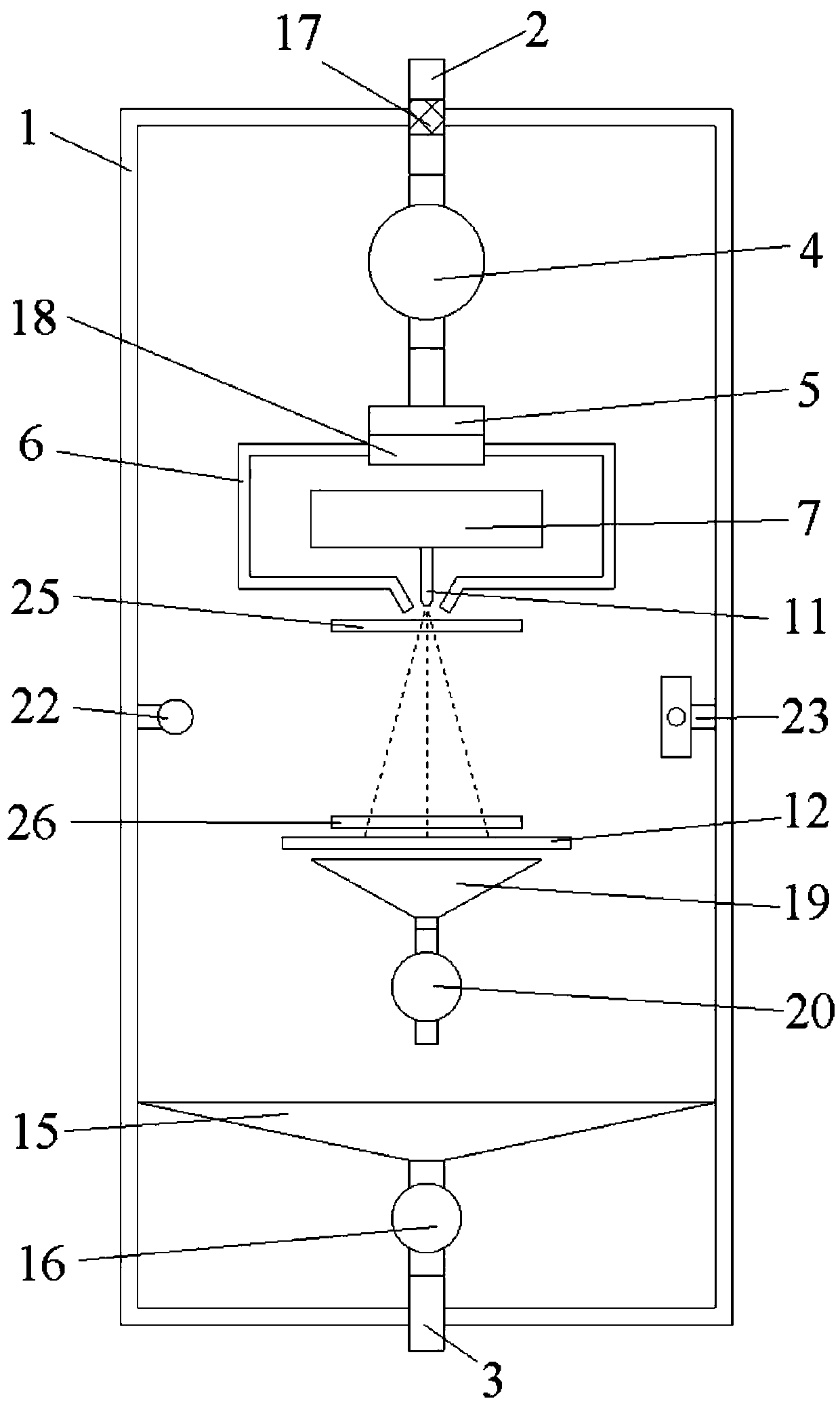

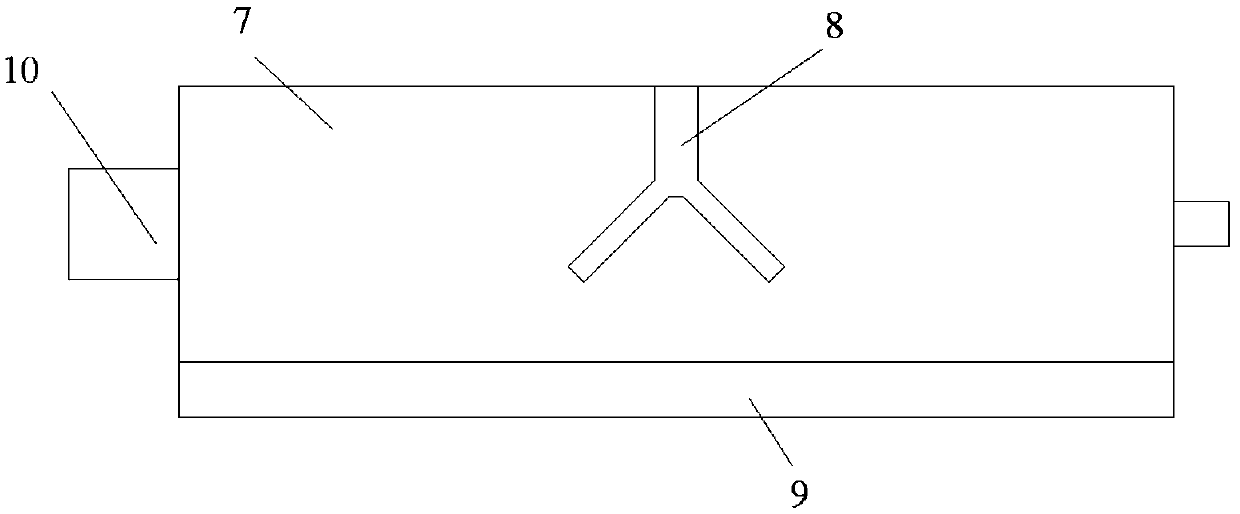

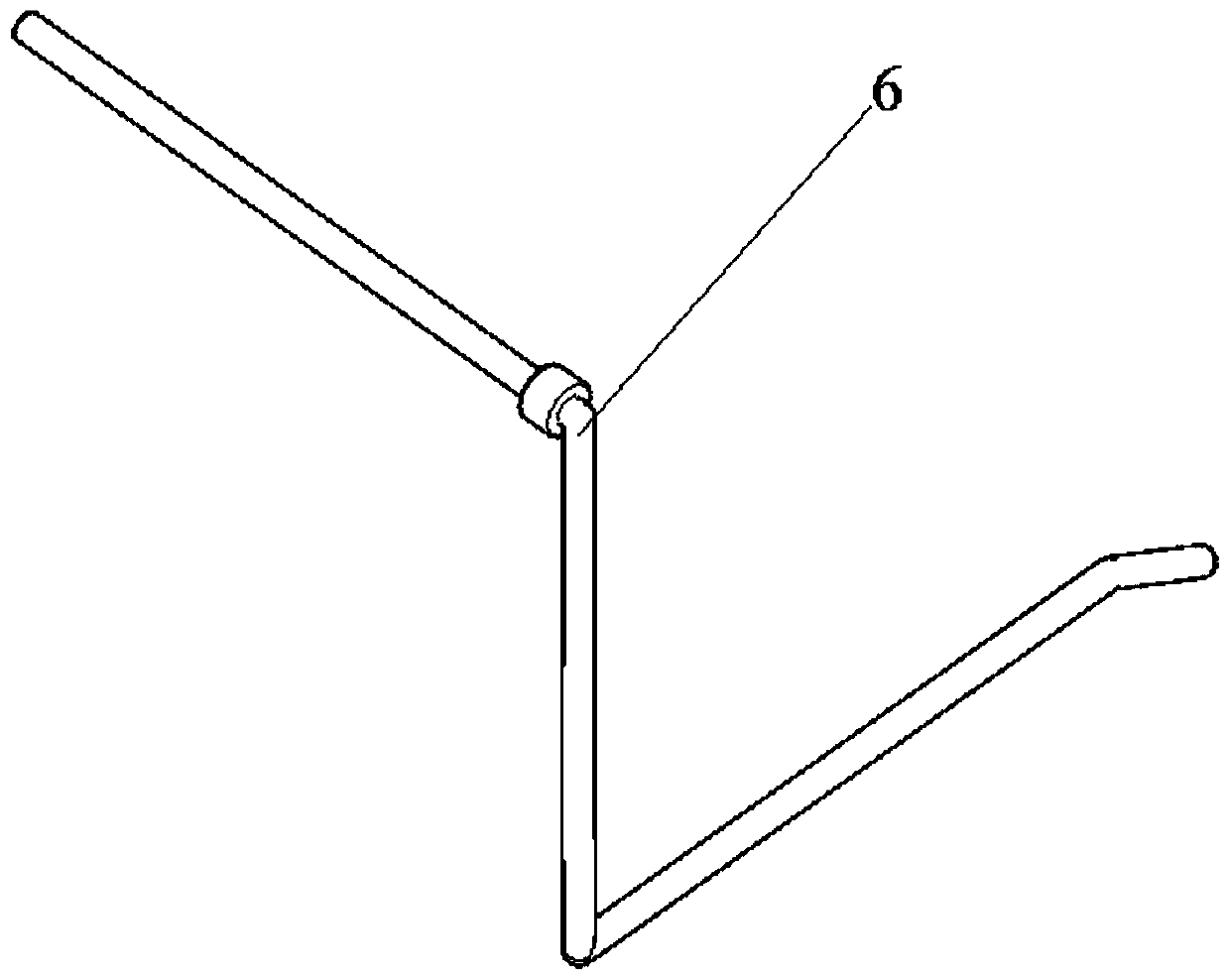

[0055] This embodiment is an exemplary embodiment of the present invention, such as Figure 1~4 As shown, among them, figure 1 It is a top view of the airtight box of this embodiment, a liquid jet spinning device, comprising an airtight box 1, the airtight box 1 includes an air inlet 2 and an air outlet 3, and the air inlet 2 is arranged at the bottom of the airtight box 1 The first end and the air outlet 3 are arranged at the second end of the airtight box 1 .

[0056] Further, a filtering device 17 is provided in the air inlet 2 , and the filtering device 17 is used to filter the gas entering through the air inlet 2 to prevent the gas from carrying impurities into the airtight box 1 .

[0057] The air inlet 2 of the airtight box 1 is connected with a high-pressure gas tank, and the air outlet 3 of the airtight box 1 is connected with an empty air storage tank.

[0058] Further, the gas input from the gas inlet 2 is an inert gas.

[0059]The air inlet device 4 is installed...

Embodiment 2

[0099] This embodiment is a preferred embodiment of the present invention, such as Figure 5 as shown, Figure 5 It is the front view of this embodiment, a liquid jet spinning device, including a closed box 1, an air intake device 4, a dehumidification device 5, a second heating device 18, an air pipe 6, a solution storage device 7, a nozzle 11, and a receiving net 12. The second funnel 19, the second air extraction device 20, the first funnel 15, the first air extraction device 16, the lighting device 22 and the camera device 23, the structures and installation methods of the above components are the same as those in Embodiment 1, and will not be repeated here. repeat.

[0100] Wherein, the position of the air outlet 3 is slightly different from the position of the air outlet 3 in Embodiment 1.

[0101] The liquid jet spinning device also includes a heating roll 21 and a universal wheel 24 .

[0102] The heating roller 21 is at least a pair, and is respectively arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com