Environment-friendly water transfer printing decal paper and preparation method thereof

A water transfer and environment-friendly technology, applied in paper, papermaking, specialty paper, etc., can solve the problems of insufficient and effective treatment of organic solvent waste gas, long drying, drying time, and reduced production efficiency, saving manpower, reducing Solvent emission, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

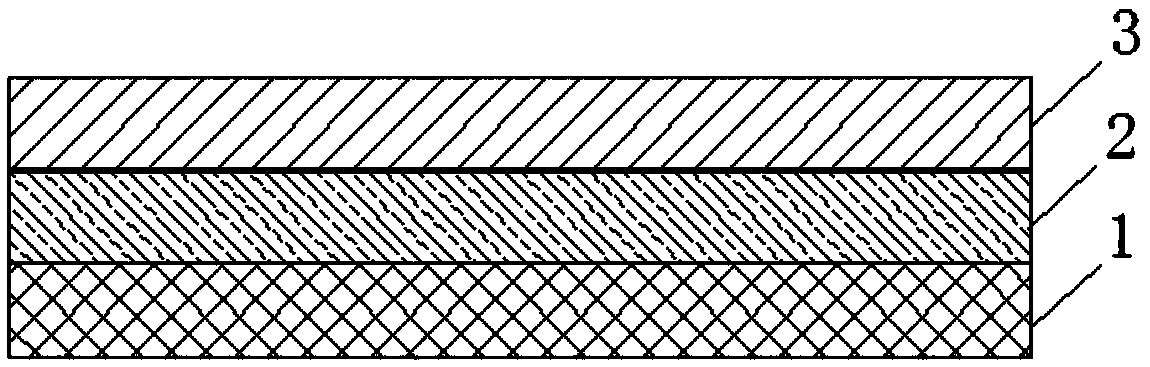

[0043] The preparation process of the existing water transfer printing decal paper is to form the printing layer 2 on the water transfer base paper 1 through screen printing, bronzing or other printing processes to obtain the target printing pattern. Then, a flexible coating film is applied to obtain a cover adhesive layer 3 . The flexible coating film is usually an acrylic resin coating material, which is printed on the pattern by screen printing.

[0044] However, such acrylic resin coatings are currently solvent-based coatings, and a large amount of organic solvent waste gas will be generated during the production and use process. In addition, most domestic water transfer printing companies are small-scale companies. It has the ability to fully and effectively treat these organic solvent waste gases, so it also causes the industry to become an industry that seriously pollutes the environment. In addition, the use of screen printing to form the coating film requires long dr...

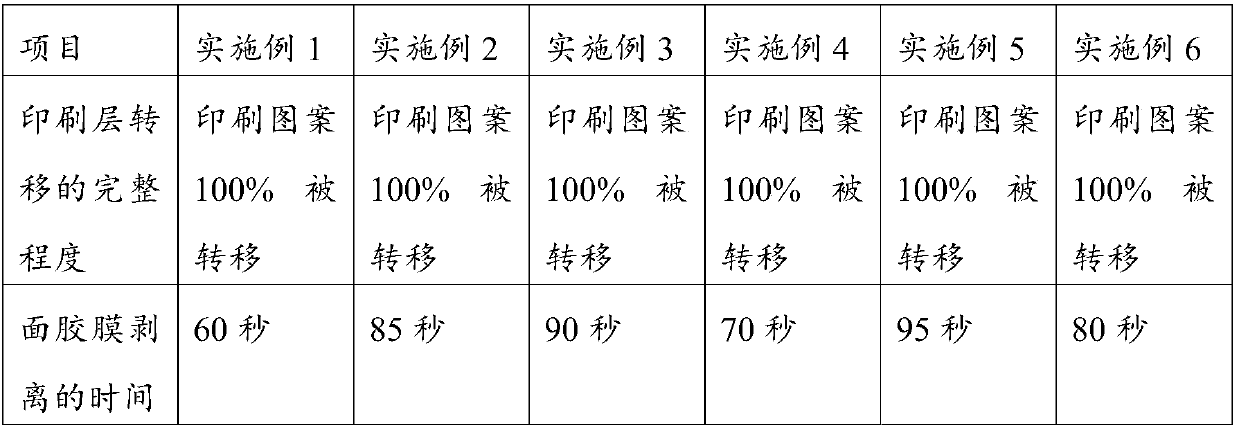

Embodiment 1

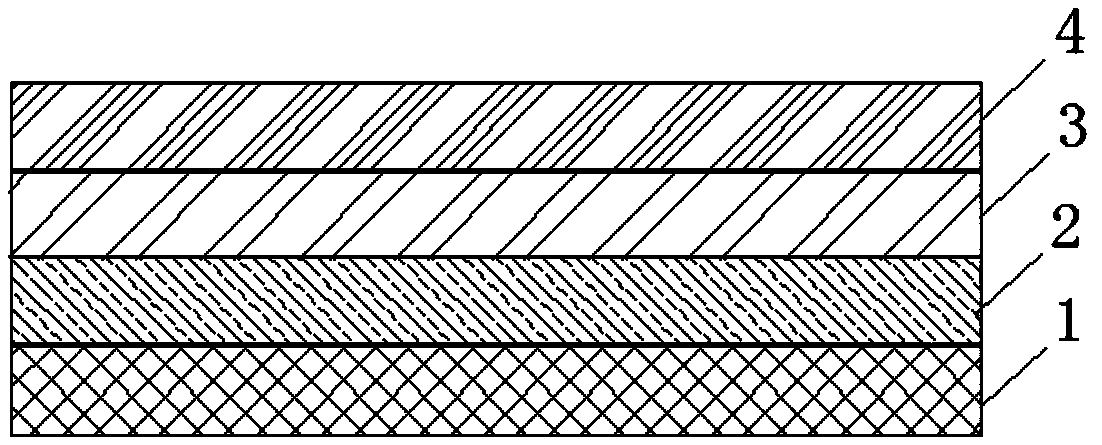

[0078] (1) Preparation of face film: The mixed resin of 60% LDPE and 40% PE elastomer is made into a film with a tensile strength of 7Mpa and a thickness of 20μm by processing processes such as film blowing, casting, calendering or laminating. The film; and corona treatment on one side to make its surface tension reach 36 dynes or more.

[0079] (2) Preparation of a face film with a self-adhesive layer: select a self-adhesive coating with a normal peel strength of 2-6N / 2.5cm, apply it to the corona-treated surface of the above-mentioned face film by a conventional method, and bake it. Drying, trimming, and winding to prepare a face film with pre-applied self-adhesive.

[0080] (3) To provide a base paper with water transfer properties.

[0081] (4) The base paper is screen-printed to form a printing layer to obtain a target printing pattern.

[0082] (5) and then compound the self-adhesive surface of the above-mentioned face adhesive film on the printing layer 2 by hot press...

Embodiment 2

[0084] (1) Preparation of face film: The mixed resin of 70% LLDPE and 30% PE elastomer is made into a film with a tensile strength of 8Mpa and a thickness of 15μm by processing processes such as film blowing, casting, calendering or laminating. film.

[0085] (2) To provide a base paper with water transfer properties.

[0086] (3) The base paper is formed into a printing layer by bronzing to obtain the target printing pattern.

[0087] (4) Use a self-adhesive coating with a normal peel strength of 2-6N / 2.5cm to print on the above printing pattern, and form a self-adhesive layer after drying.

[0088] (5) compounding the facial adhesive film on the self-adhesive layer by hot pressing to obtain the finished flower paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Normal peel strength | aaaaa | aaaaa |

| Normal peel strength | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com