Vibration reduction ring based on annular piezoelectric stack

A ring-shaped piezoelectric and vibration-damping ring technology, applied in non-rotational vibration suppression and other directions, can solve the problems of difficult installation and processing, poor environmental adaptability, short service life, etc. awesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

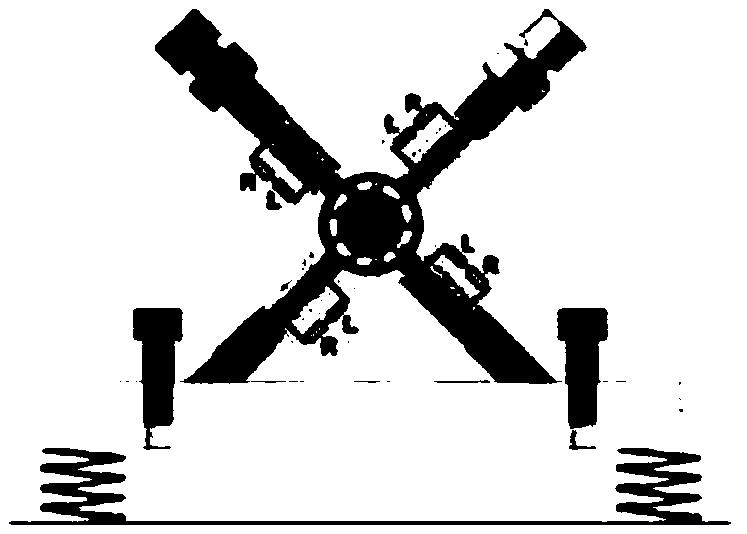

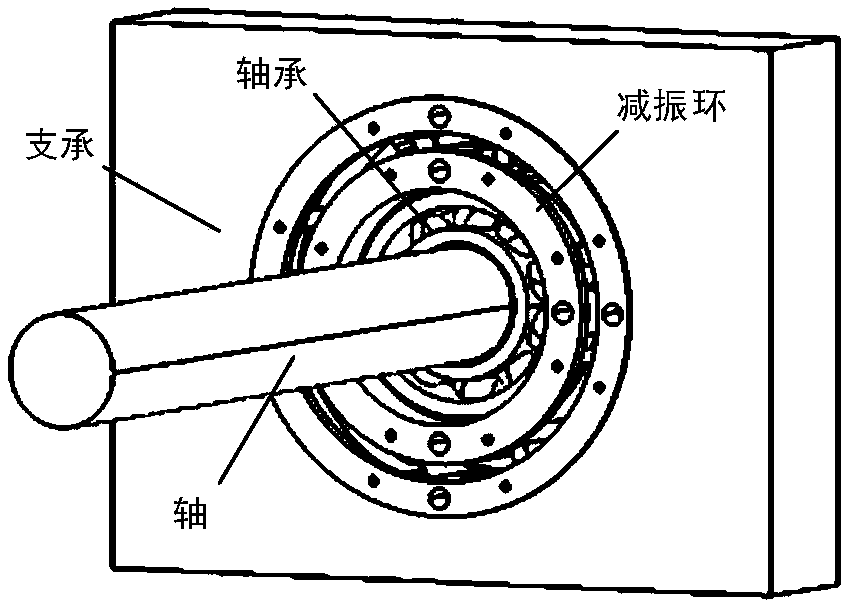

[0025] The present invention is installed between bearings and supports, gears and shafts in the rotor system, such as image 3 shown. It is mainly used to reduce the output force to the support caused by vibration, thereby reducing the vibration response of the overall structure. The fork-shaped protection frame of the vibration damping ring can protect the piezoelectric stack from being damaged by tangential force and torque, and improve the service life and stability of the piezoelectric stack.

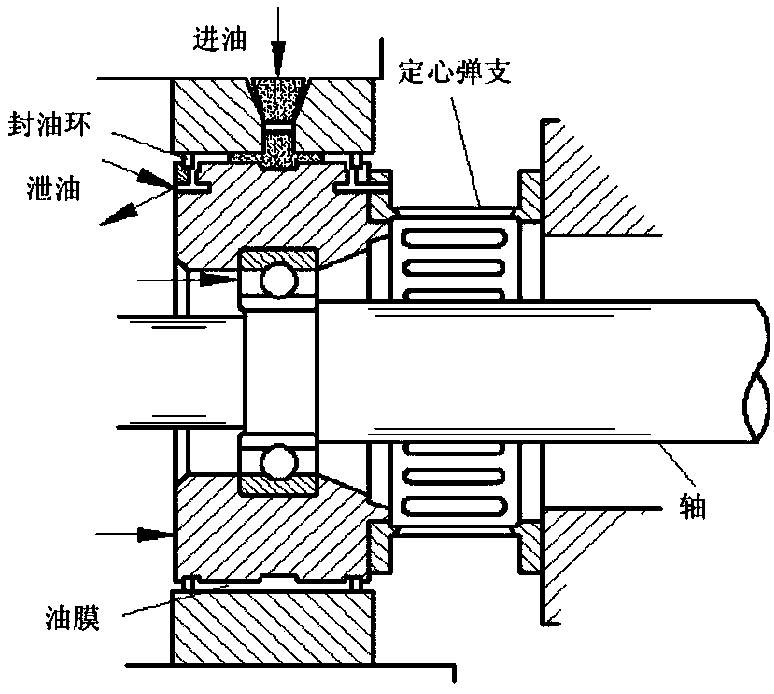

[0026] The structure of the present invention is as Figure 8 As shown, it includes a ring-shaped piezoelectric stack (1), a protection frame (2) and an external shunt circuit (5), wherein the protection frame (2) is a ring-mounted structure sleeved on the bearing (4), as shown in Figure 7 As shown, the protective frame (2) is composed of two upper and lower U-shaped protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com