Electrostatic controllable abrasive grain flow machining removal amount detection device and detection method

A detection method and abrasive particle flow technology, applied in the direction of measuring devices, used abrasive processing devices, metal processing equipment, etc., can solve the problem that the processing quality is not easy to improve, the process parameters are difficult to control, and the Preston equation is not applicable, etc. problem, to achieve the effect of improving the surface of the substrate with less, high-efficiency ultra-smooth surface processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

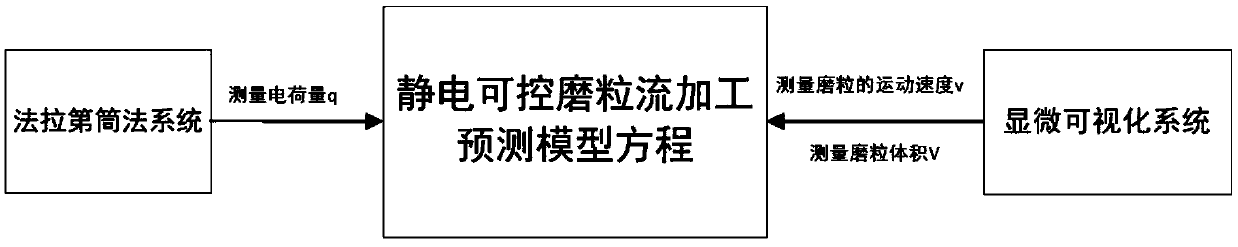

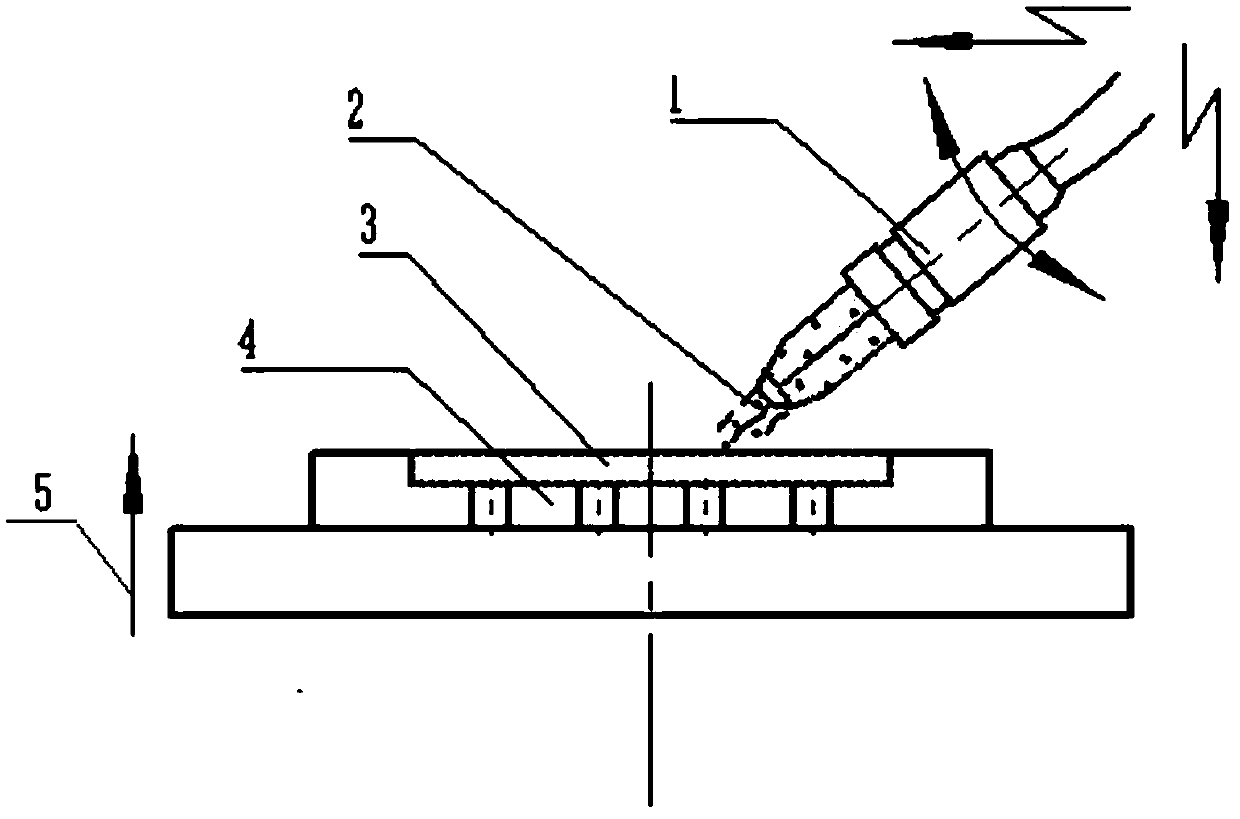

[0027] Such as Figure 1-6As shown in , an electrostatic controllable abrasive flow processing removal amount detection device includes an abrasive flow processing device, a Faraday cylinder method system and a microscopic visualization system. The abrasive flow processing system includes a high-voltage electrostatic generator 1, a Die adsorption platform 4, external electric field 5, abrasive particle flow 2 and workpiece 3, workpiece 3 is fixed by matching mold adsorption platform 4, abrasive particle flow 2 is launched to the surface of workpiece 3 after passing through high-voltage electrostatic generator 1 for abrasive flow processing, The external electric field 5 is directly loaded on the entire mold matching adsorption platform 4 and the workpiece 3 .

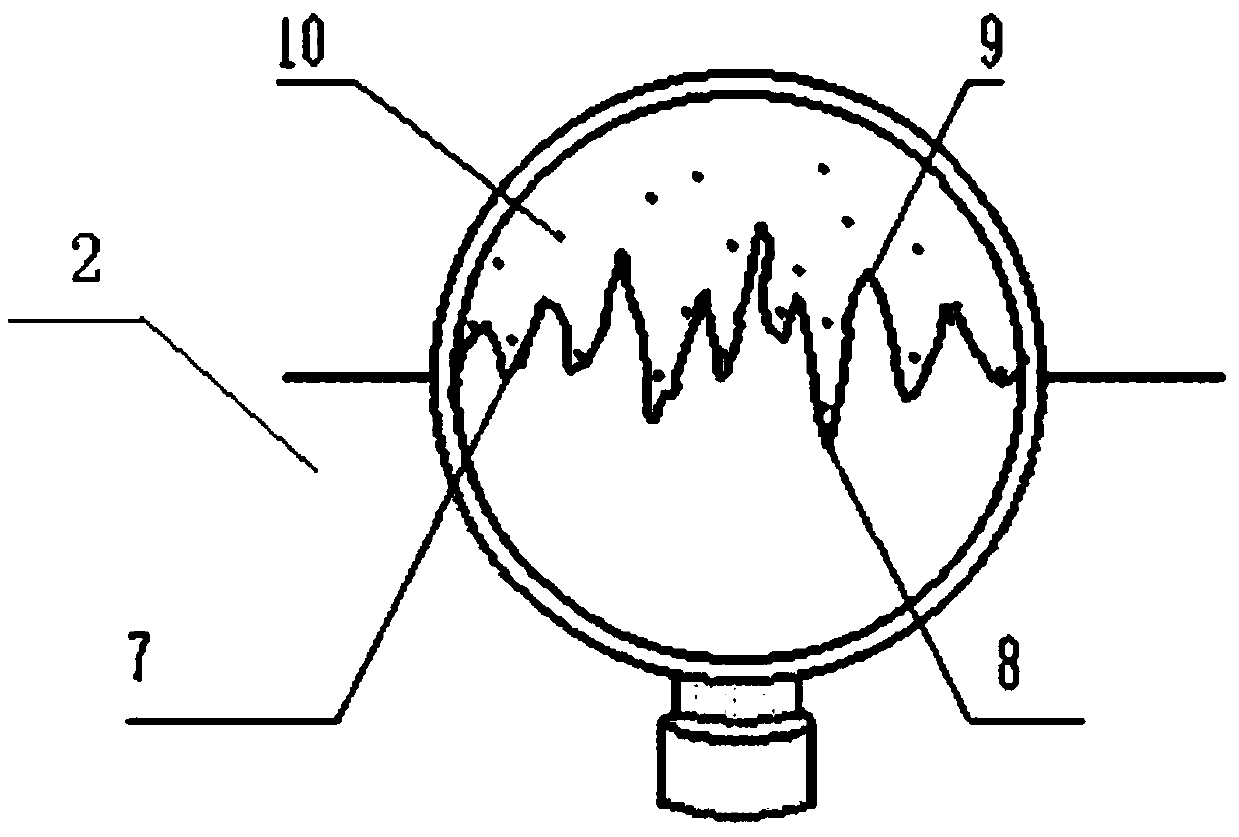

[0028] When the abrasive flow processing device is working, the actual processing surface 7 of the workpiece 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com