A mask and its manufacturing method

A mask and substrate technology, applied in the field of mask, can solve the problems of increasing the reject rate, affecting the production accuracy of products, alignment deviation, etc., and achieving the effects of reducing the reject rate, the number of exposures, and the number of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 provides a mask.

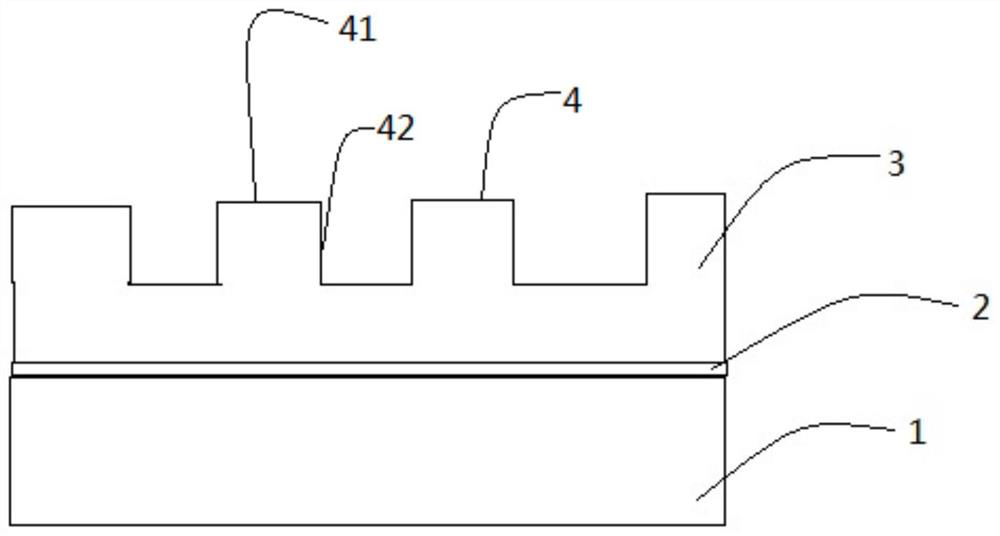

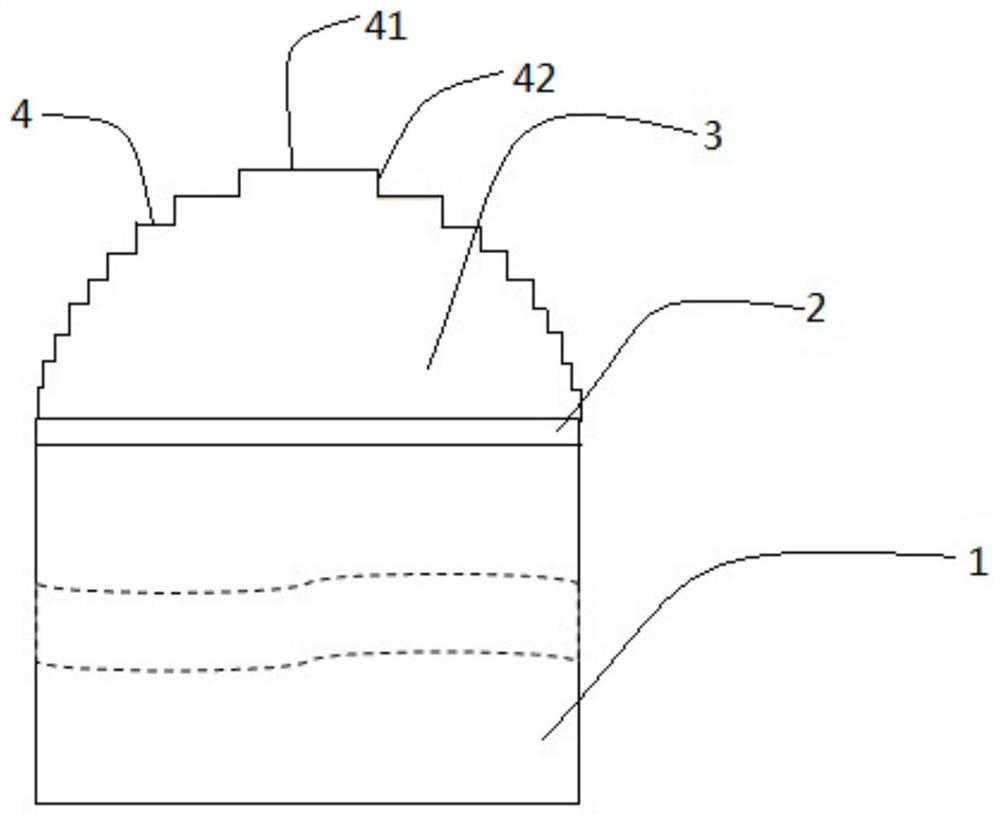

[0019] Please refer to figure 1 , in one embodiment, the mask plate includes: a substrate 1 and a photoresist layer 3, the photoresist layer 3 is arranged on the substrate 1, the side of the photoresist layer 3 in contact with the product is a top wall 4, and the top wall 4 has at least two Two bonding surfaces 41 parallel to the substrate 1 have different heights. Adjacent bonding surfaces 41 are connected by a connecting wall 42 perpendicular to the substrate 1. The top wall 4 is used to record three-dimensional structure information. The height of the bonding surface 41 refers to the vertical distance from the bonding surface 41 to the substrate 1 .

[0020] Please continue to refer figure 1 , the mask plate further includes a light-blocking metal layer 2 , and the light-blocking metal layer 2 is disposed between the substrate 1 and the photoresist layer 3 .

[0021] Specifically, the substrate 1 , the light-blocking metal layer 2 a...

Embodiment 2

[0027] This embodiment provides a method for fabricating a mask, specifically a method for fabricating the mask in Embodiment 1.

[0028] The software and hardware required to make a mask are:

[0029] The raw material board, the raw material board includes a substrate, a light-blocking metal layer and a photoresist layer (unprocessed), and the thickness of the photoresist layer 3 is between 200nm and 10000nm. A direct-write lithography machine with repeatable exposure that can change parameters such as focal depth and energy, and a software server with AUTOCAD installed and capable of processing DWG, DXF and other formats.

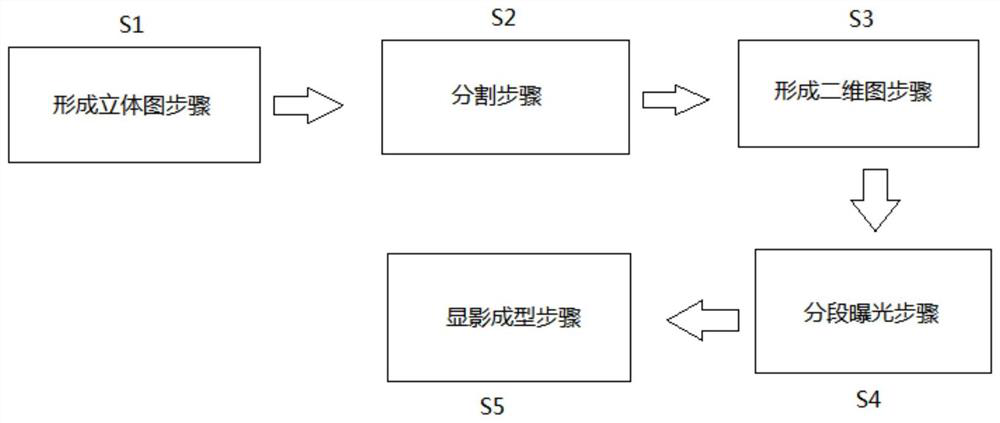

[0030] Please refer to image 3 , Figure 4 and Figure 5 , in one embodiment, the manufacturing method includes:

[0031] In step S1 of forming a stereogram, the shape of the product matches the shape of the photoresist layer 3 , and a three-dimensional stereogram of the photoresist layer 3 of the mask plate to be produced is formed according to the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com