Self-compacting reactive powder concrete as well as preparation method and application thereof

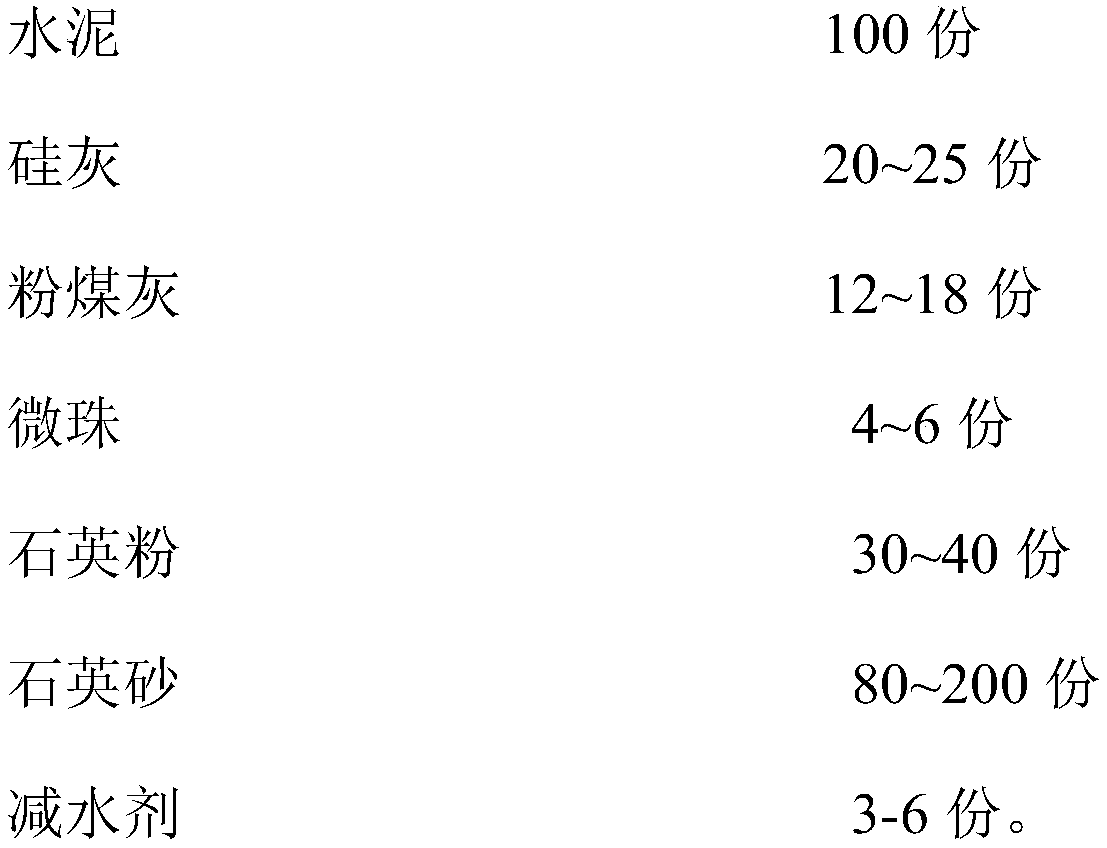

An active powder, self-compacting technology, applied in the field of building materials, can solve the problems of difficulty in stirring and molding, complex preparation process, low water-to-binder ratio, etc., and achieve the effects of good strength, simple preparation process and good construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

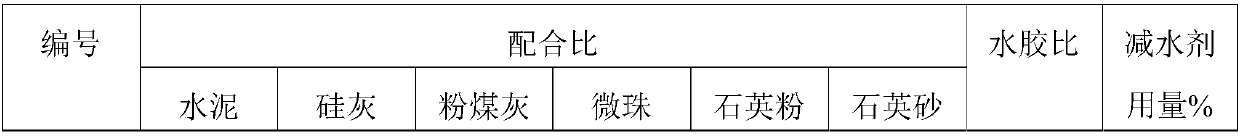

[0048] Examples 1 to 5: Self-compacting reactive powder concrete under different water-binder ratios.

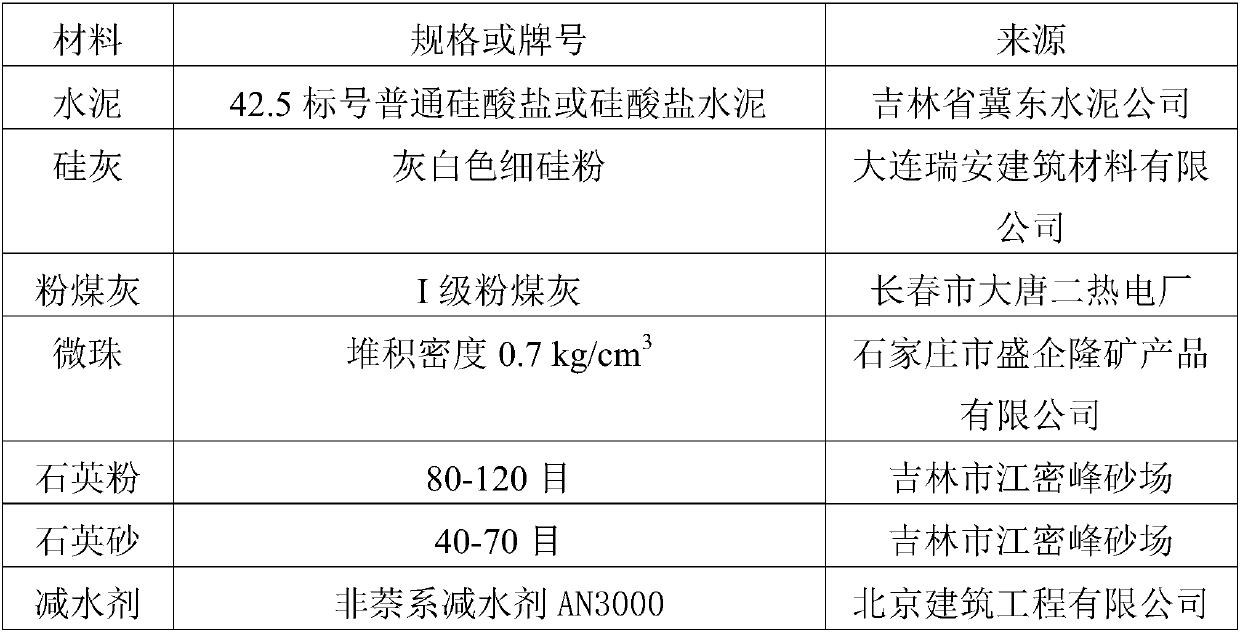

[0049] See Table 2 for the raw materials, and see Table 3 for the properties of the prepared self-compacting reactive powder concrete.

[0050] Preparation:

[0051] (1) Take each raw material according to Table 2, pour quartz powder and quartz sand (a mixture of fine sand, medium sand and coarse sand) into the mixer, and dry mix until the materials of four particle sizes are evenly mixed;

[0052](2) Pour the cement, silica fume, fly ash and microbeads into the mixer, and dry stir until the mixture of the gel material and the quartz sand is uniform, and the time is about 3 to 5 minutes;

[0053] (3) Mix the water and the new non-naphthalene-based water reducer AN3000 evenly, divide them into two parts, put half into the blender, stir for about 5-8 minutes, then add the remaining half into the blender, stir evenly to form a slurry Body, that is, the required self-compactin...

Embodiment 6~ Embodiment 11

[0062] Example 6 to Example 11: Self-compacting active powder concrete under different silica fume cement ratios. See Table 4 for the raw materials, and see Table 5 for the properties of the prepared self-compacting reactive powder concrete.

[0063] Preparation:

[0064] (1) Take each raw material according to Table 4, pour quartz powder and quartz sand (a mixture of fine sand, medium sand and coarse sand) into the mixer, and dry mix until the materials of four particle sizes are evenly mixed;

[0065] (2) Pour the cement, silica fume, fly ash and microbeads into the mixer, and dry stir until the mixture of the gel material and the quartz sand is uniform, and the time is about 3 to 5 minutes;

[0066] (3) Mix the water and the new non-naphthalene-based water reducer AN3000 evenly, divide them into two parts, put half into the blender, stir for about 5-8 minutes, then add the remaining half into the blender, stir evenly to form a slurry Body, that is, the required self-compa...

Embodiment 16~ Embodiment 20

[0087] Examples 16 to 20: Self-compacting reactive powder concrete with different amounts of quartz powder.

[0088] See Table 8 for the raw materials, and see Table 9 for the properties of the prepared self-compacting reactive powder concrete.

[0089] Preparation:

[0090] (1) Take each raw material according to Table 8, pour quartz powder and quartz sand (a mixture of fine sand, medium sand and coarse sand) into the mixer, and dry mix until the materials of four particle sizes are evenly mixed;

[0091] (2) Pour the cement, silica fume, fly ash and microbeads into the mixer, and dry stir until the mixture of the gel material and the quartz sand is uniform, and the time is about 3 to 5 minutes;

[0092] (3) Mix the water and the new non-naphthalene-based water reducer AN3000 evenly, divide them into two parts, put half into the blender, stir for about 5-8 minutes, then add the remaining half into the blender, stir evenly to form a slurry Body, that is, the required self-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com