Nanometer heat insulating coating for buildings and preparation method thereof

A kind of construction and heat insulation technology, applied in the direction of reflection/signal coating, anti-fouling/underwater coating, coating, etc., can solve the problems of large influence of overall architectural decoration, difficulty of engineering accidents, large influence of decoration, etc., and achieve deceleration Curing efficiency, reducing the probability of biological destruction, and reducing the effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

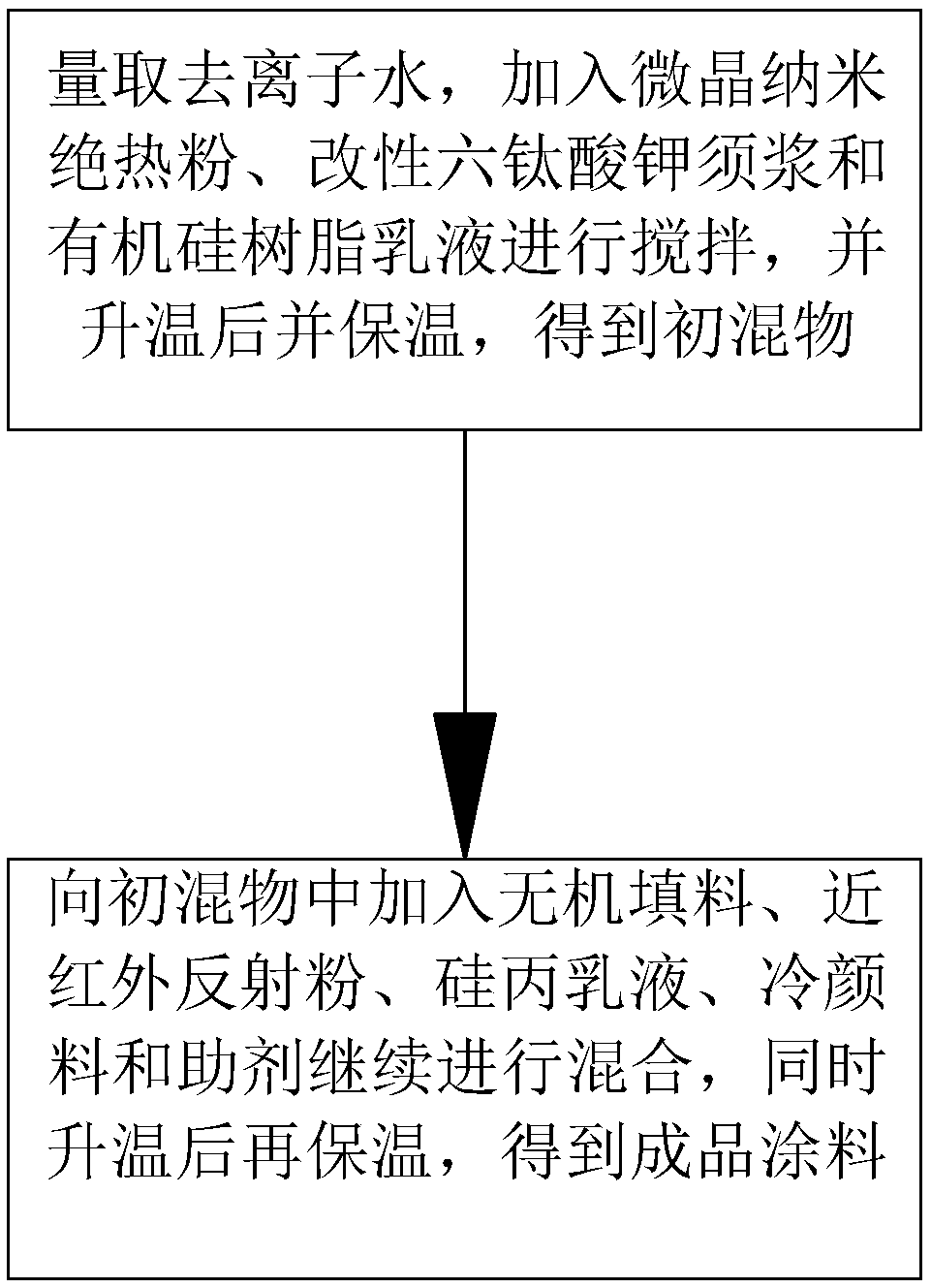

[0033] A kind of preparation method of nano heat-insulating coating for building, comprises the following steps:

[0034] Step 1. First measure 10Kg of deionized water, then add 20Kg of microcrystalline heat-insulating nano-powder, 3Kg of modified potassium hexatitanate whisker slurry and 15Kg of silicone resin emulsion to fully stir. The stirring speed is 500rpm, and the temperature Raise to 40°C and continue stirring for 1h to obtain the primary mixture;

[0035]Step 2. Add 10Kg of inorganic filler, 5Kg of near-infrared reflective powder, 5Kg of silicon acrylic emulsion, 4Kg of cold pigment and 2Kg of additives to the initial mixture in step 1, and continue mixing. The stirring speed is 600rpm, and the temperature continues to rise Stir to 80°C for 3 hours, and obtain the finished coating after being fully dispersed.

[0036] Among them, the microcrystalline thermal insulation nano powder can be purchased from Huntsman, UK, the near-infrared reflective powder can be purchas...

Embodiment 2

[0039] A kind of preparation method of nano thermal insulation paint for building, it is different from embodiment one, comprises the following steps:

[0040] Step 1. First measure 20Kg of deionized water, then add 40Kg of microcrystalline adiabatic nano-powder, 5Kg of modified potassium hexatitanate whisker slurry and 25Kg of silicone resin emulsion to fully stir. The stirring speed is 700rpm, and the temperature Raise to 50°C and continue stirring for 2 hours to obtain the primary mixture;

[0041] Step 2. Add 20Kg of inorganic filler, 9Kg of near-infrared reflective powder, 15Kg of silicon acrylic emulsion, 6Kg of cold pigment and 3Kg of additives to the initial mixture in step 1, and continue mixing. The stirring speed is 1000rpm, and the temperature continues to rise Stir to 90°C for 5 hours, and obtain the finished coating after being fully dispersed.

Embodiment 3

[0043] A kind of preparation method of nano thermal insulation paint for building, it is different from embodiment one, comprises the following steps:

[0044] Step 1. First measure 15Kg of deionized water, then add 30Kg of microcrystalline heat-insulating nano-powder, 4Kg of modified potassium hexatitanate whisker slurry and 20Kg of silicone resin emulsion to fully stir. The stirring speed is 600rpm, and the temperature Raise to 45°C and continue stirring for 1.5h to obtain the primary mixture;

[0045] Step 2. Add 15Kg of inorganic filler, 7Kg of near-infrared reflective powder, 10Kg of silicon acrylic emulsion, 5Kg of cold pigment and 2.5Kg of additives to the initial mixture in step 1, and continue mixing. The stirring speed is 800rpm, and the temperature continues to rise. The temperature is as high as 85°C, and the stirring is continued for 4 hours, and the finished coating is obtained after being fully dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com