Aeolian sand roadbed and construction method thereof

A construction method and aeolian sand technology, applied in the field of aeolian sand embankment and its construction, can solve the problems of difficult forming, low shear strength, and low cohesion, so as to improve compaction and construction performance, and solve problems encountered Water is easy to agglomerate and the effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

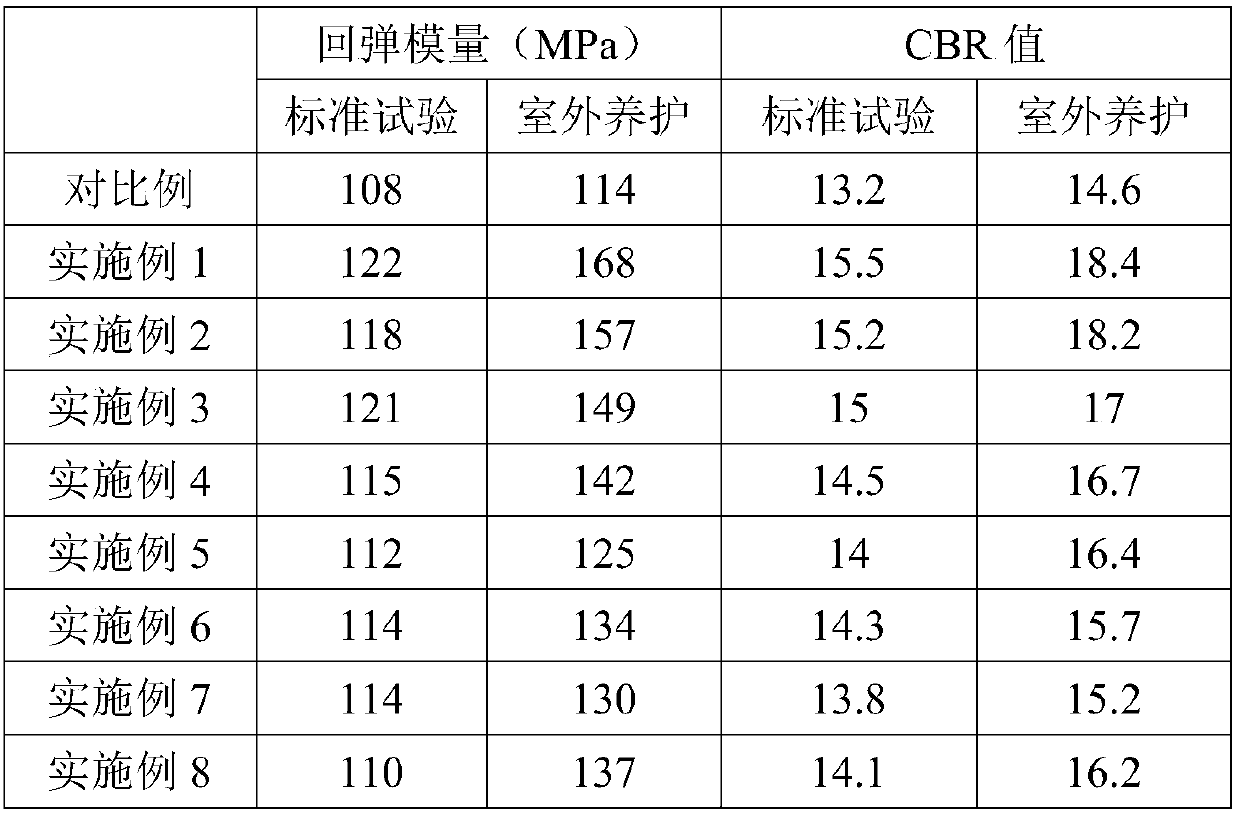

Embodiment 1

[0029] As shown in Table 1, the aeolian sand subgrade includes 100 parts by mass of aeolian sand, 1.5 parts of modifier, and 12 parts of wetting water; wherein the modifier includes each component by mass percentage: Redispersibility Rubber powder 6%, tackifier 26% (tackifier is viscosity 1.0×10 5 mpa.s of hydroxyethyl cellulose (HEC), dispersant 2% (sodium carbonate), and the balance is water.

Embodiment 2

[0031] As shown in Table 1, the aeolian sand subgrade includes 100 parts by mass of aeolian sand, 1.5 parts of modifier, and 12.5 parts of wetting water; wherein the modifier includes each component by mass percentage: Redispersibility Rubber powder 4%, tackifier 28% (tackifier is viscosity 1.0×10 5 mpa.s sodium carboxymethylcellulose (CMC), dispersant 1% (sodium carbonate), and the balance is water.

Embodiment 3

[0033] As shown in Table 1, the aeolian sand subgrade includes 100 parts by mass of aeolian sand, 1.6 parts of modifier, and 13 parts of wetting water; wherein the modifier includes each component by mass percentage: Redispersibility Rubber powder 3%, tackifier 27% (tackifier is viscosity 1.0×10 5 mpa.s polyaluminum chloride (PAC), dispersant 3% (sodium carbonate), and the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com