A pressure controller and communication method of a proportional valve for vehicles based on CAN bus

A technology of CAN bus and communication method, which is applied in the communication field of vehicle proportional valve pressure controller, and can solve the problems of unable to carry data protocol, unable to output the internal state of proportional valve, limited information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

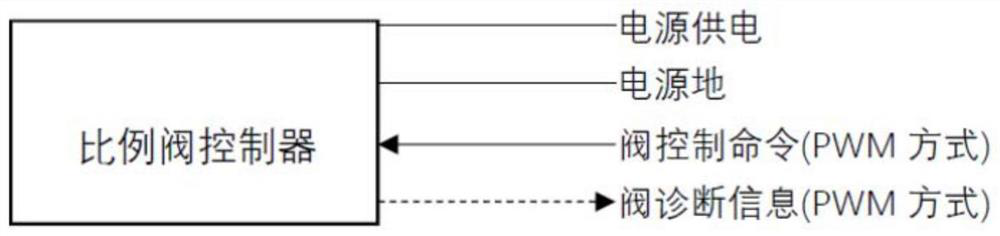

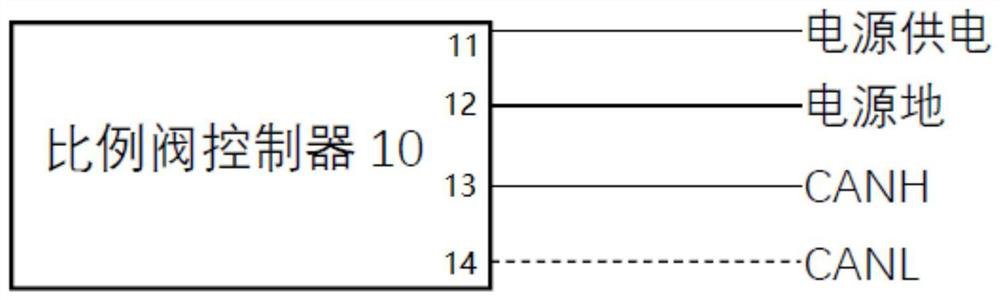

[0039] This example is aimed at the functional characteristics of the vehicle proportional valve controller and the vehicle ECU. For the communication method between the two, the PWM communication method that has been used in the prior art is abandoned, and the CAN bus interface is used instead of the PWM interface. Based on the CAN bus Message protocol to realize more complex communication functions, obtain higher control precision and higher reliability, and release valuable PWM resources of ECU at the same time.

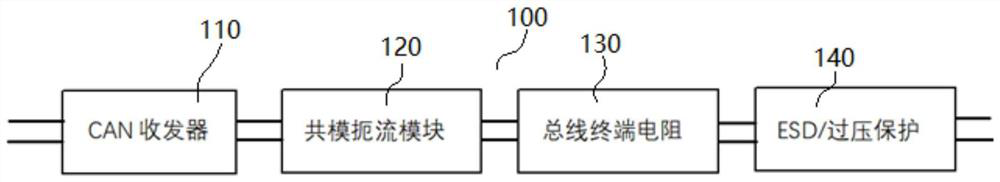

[0040] As an example, based on the above principles, this program provides a CAN bus-based vehicle proportional valve pressure controller, which can be directly connected to the ECU on the vehicle through the CAN bus, and based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com