P-type crystalline silicon solar cell and preparation method thereof

A technology of crystalline silicon solar cells and p-type silicon, applied in the field of solar cells, can solve problems such as limiting battery open circuit voltage and other performance parameters, increasing recombination and loss, etc., achieve high open circuit voltage and photoelectric conversion efficiency, reduce recombination and loss, The effect of increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Such as Figure 1 to Figure 7 As shown, this embodiment provides a method for preparing a p-type crystalline silicon solar cell, comprising steps:

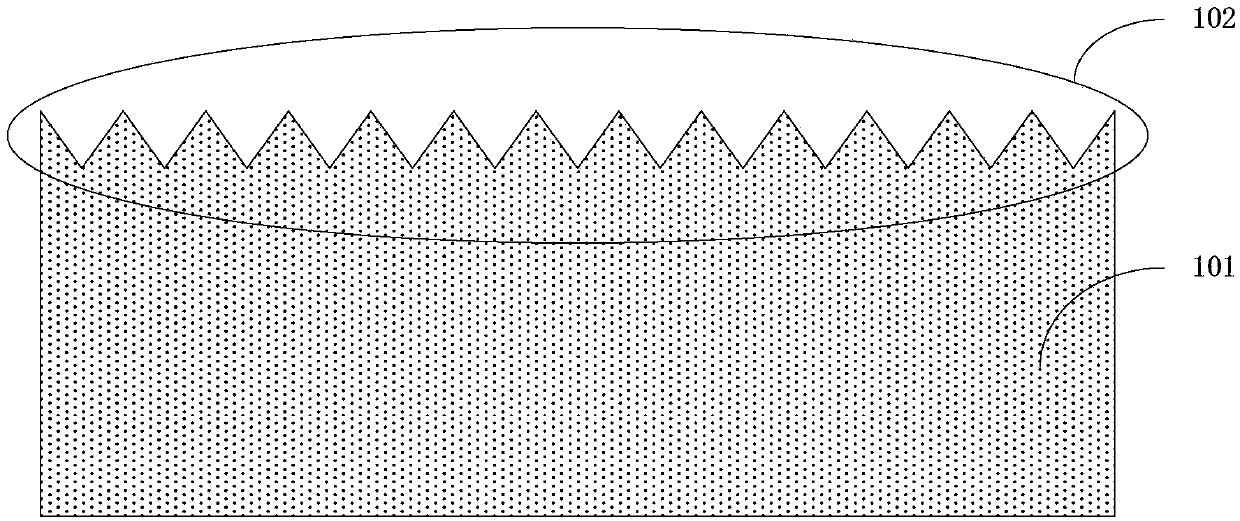

[0077] Such as figure 1 As shown, perform step 1) to provide a p-type crystalline silicon substrate 101, and use texturing treatment to form a textured light-trapping structure 102 on the front surface of the p-type crystalline silicon substrate 101.

[0078] As an example, the thickness of the p-type crystalline silicon substrate 101 is between 40-200 μm, the resistivity of the p-type crystalline silicon substrate 101 is between 0.5-3 Ω·cm, and the p-type crystalline silicon substrate 101 may be a single crystal Silicon can also be polysilicon.

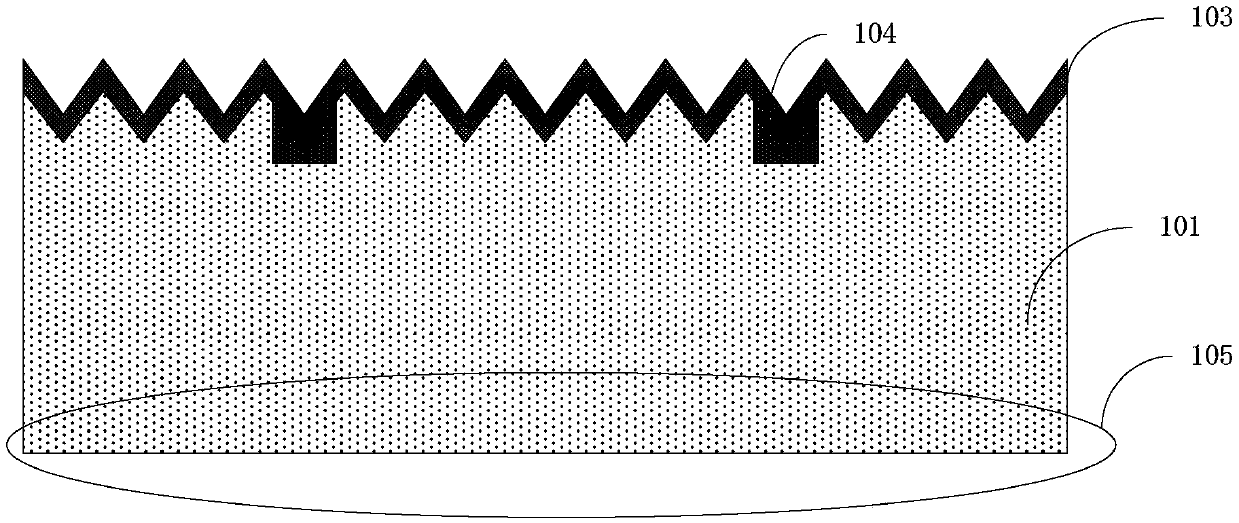

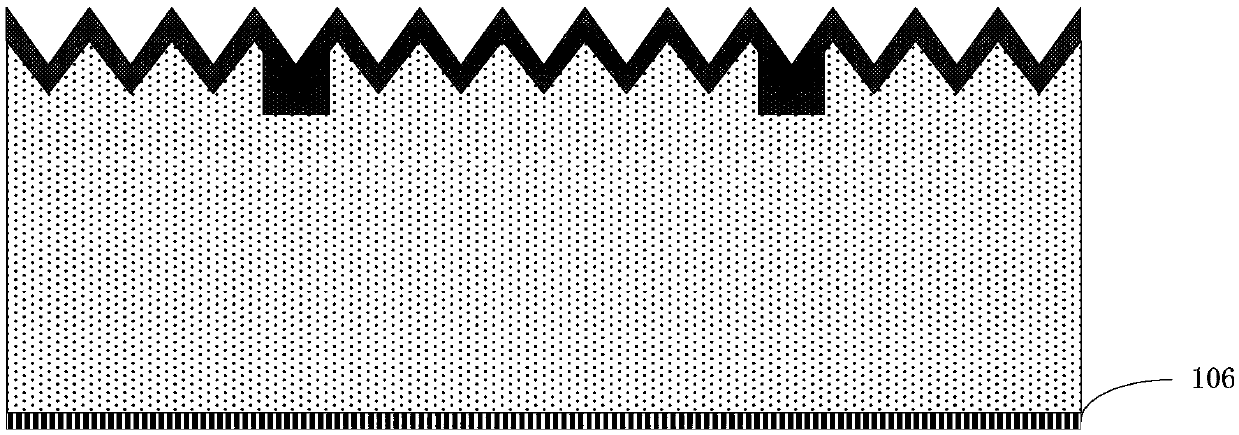

[0079] Such as figure 2 As shown, proceed to step 2) form an n-type doped layer 103 on the front surface of the p-type crystalline silicon substrate 101 by using phosphorus diffusion process, and the n-type doped layer 103 forms a pn junction with the p-type crystalline silico...

Embodiment 2

[0128] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is only that: in this embodiment, no heavily doped n-type layer 104 is provided.

[0129] Table 1

[0130]

[0131]Table 1 is the battery performance parameters of Example 1 and Example 2.

[0132] In summary, the present invention provides a p-type crystalline silicon solar cell and its preparation method, which have the following effects:

[0133] A heavily doped n-type layer 104 is formed on the front surface of the p-type crystalline silicon substrate 101, and the heavily doped n-type layer 104 has a certain promoting effect on the overall performance of the solar cell.

[0134] The shape 105 of the back surface of the p-type crystalline silicon substrate 101 includes a plane and textured light-trapping structure. When light is incident from the front surface of the p-type crystalline silicon substrate 101, the structure with a planar back surface has a relatively large short-ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com