A kind of degradable agricultural mulch film and preparation method thereof

A technology of agricultural mulching film and mulching film, which is applied in botany equipment and methods, chemical instruments and methods, agriculture, etc., and can solve the problems of environmental impact of degradation products of degradation performance, processing difficulties, poor heat preservation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Mix the factory waste fibers (wool, flax) in a mass ratio of 1:1, spray 2-3% emulsifier evenly, and pile them up for 12 hours before use.

[0053] (2) Opening and mixing the natural fiber waste, carding and feeding, laying and forming, to obtain a fiber web;

[0054] Opening and mixing: the air volume of dust removal treatment is 18m / h when passing through the multi-bin cotton mixer;

[0055] Carding and feeding: Roller-cylinder carding mechanism is adopted, and messy rollers are attached to uniform the fiber web structure. Among them, the diameter of the cylinder is 850mm, the rotation speed of the cylinder is 70r / min, the width is 2000mm, and the weight of the thin net after carding is 10±1g / m 2 .

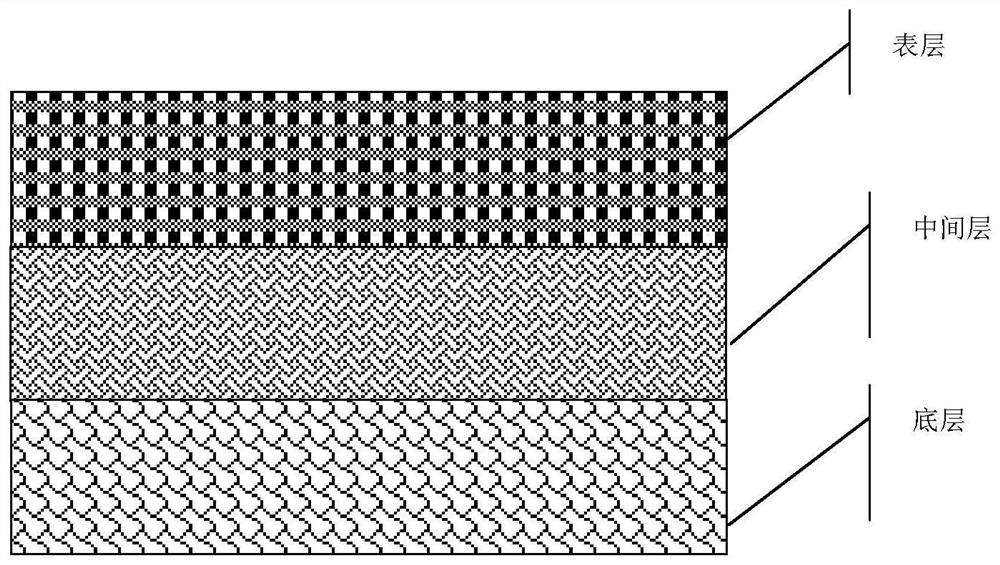

[0056] Laying forming: the combination of cross-laying and press-in air-laying is adopted to form the bottom layer with parallel laying of fibers as the main structure, and the middle layer and surface layer are subjected to the action of press-in airflow to form lig...

Embodiment 2

[0065] (1) Mix the factory waste fibers (wool, flax, PLA) in a mass ratio of 45:45:10, spray evenly with 2-3% emulsifier, and pile them up for 12 hours before use.

[0066] (2) Opening and mixing the natural fiber waste, carding and feeding, laying and forming, to obtain a fiber web;

[0067] Opening and mixing: the air volume of dust removal treatment is 22m / h when passing through the multi-bin cotton mixer;

[0068] Carding and feeding: Roller-cylinder carding mechanism is adopted, and messy rollers are attached to uniform the fiber web structure. Among them, the diameter of the cylinder is 850mm, the rotation speed of the cylinder is 70r / min, the width is 2000mm, and the weight of the thin net after carding is 10±1g / m 2 .

[0069] Laying forming: the combination of cross-laying and press-in air-laying is adopted to form the bottom layer with parallel laying of fibers as the main structure, and the middle layer and surface layer are subjected to the action of press-in airf...

Embodiment 3

[0078] (1) Mix the factory waste fiber (cotton, flax) in a mass ratio of 1:2, spray evenly with 1% emulsifier and 1% water, and pile it up for 12 hours before use.

[0079] (2) Opening and mixing the natural fiber waste, carding and feeding, laying and forming, to obtain a fiber web;

[0080] Opening and mixing: the air volume of dust removal treatment is 18m / h when passing through the multi-bin cotton mixer;

[0081] Carding and feeding: Roller-cylinder carding mechanism is adopted, and messy rollers are attached to uniform the fiber web structure. Among them, the diameter of the cylinder is 850mm, the rotation speed of the cylinder is 70r / min, the width is 2000mm, and the weight of the thin net after carding is 10±1g / m 2 .

[0082] Laying forming: the combination of cross-laying and press-in air-laying is adopted to form the bottom layer with parallel laying of fibers as the main structure, and the middle layer and surface layer are subjected to the action of press-in airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com