Preparation method of flavored oyster sauce

A technology of oyster sauce and flavor, which is applied in the direction of food ingredients as odor improvers, food ingredients as taste improvers, food ingredients as thickeners, etc. It can solve the problems of undisclosed oyster sauce, etc., to increase the thickness of the taste and eliminate the fishy smell Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

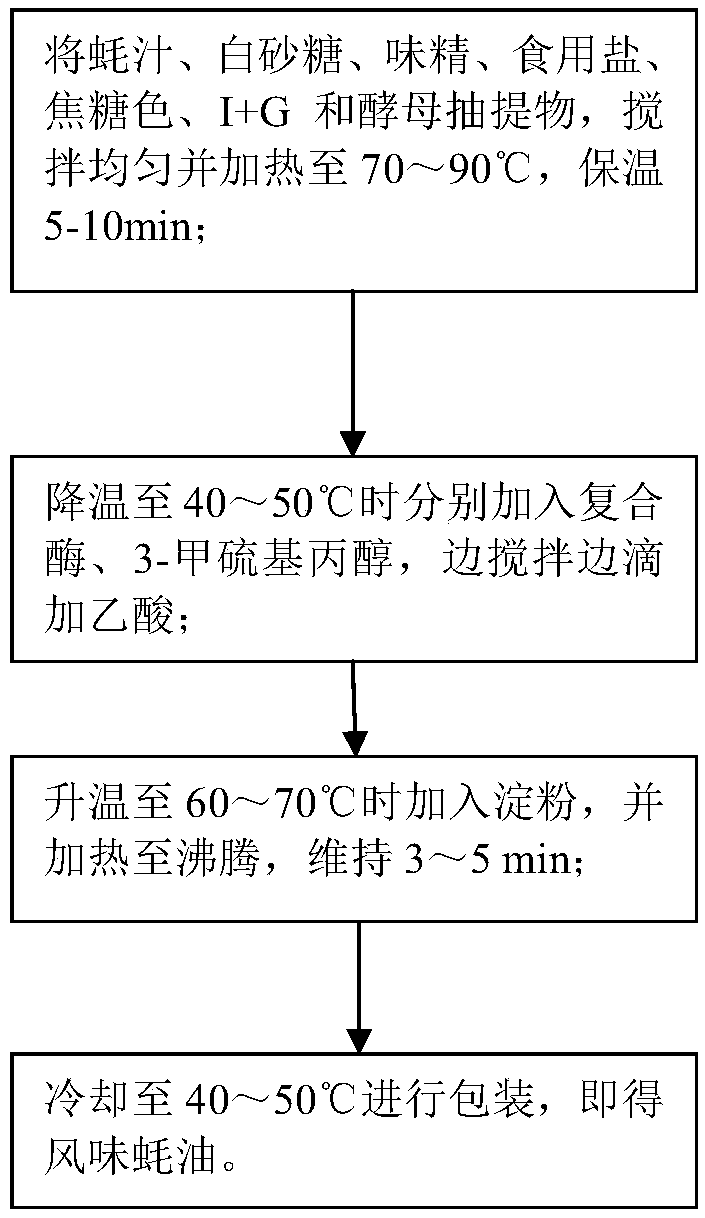

[0027] A kind of embodiment of the preparation method of flavor oyster sauce among the present invention (referring to figure 1 ), including the following steps:

[0028] Stir oyster juice, white sugar, monosodium glutamate, edible salt, caramel color, I+G and yeast extract evenly, the quality of oyster juice, white sugar, monosodium glutamate, edible salt, caramel color, I+G, and yeast extract The ratio is 3: 8: 6: 5: 1: 0.1: 0.1 to obtain a semi-finished mixed solution, and heat it to 70°C and keep it warm for 5 minutes; when the above mixed solution is cooled to 40°C, add 3-methylthiopropanol, alkaline Protease and neutral protease are mixed evenly, the mass ratio of 3-methylthiopropanol, alkaline protease, neutral protease and oyster juice is 2:0.01:0.005:5, and the stirring speed of the mixed solution is 100r / min, Continue to stir, and add acetic acid dropwise while stirring; the drop rate of acetic acid is 2g / min, and the mass ratio of 3-methylthiopropanol to acetic aci...

Embodiment 2

[0030] A kind of embodiment of the preparation method of flavor oyster sauce among the present invention (referring to figure 1 ), including the following steps:

[0031] Stir oyster juice, white sugar, monosodium glutamate, edible salt, caramel color, I+G and yeast extract evenly, the quality of oyster juice, white sugar, monosodium glutamate, edible salt, caramel color, I+G, and yeast extract The ratio is 5:10:8:7:1.5:0.6:2 to obtain a semi-finished mixed solution, which is heated to 80°C and kept for 7 minutes; when the above mixed solution is cooled to 45°C, 3-methylthiopropanol, alkaline Protease and neutral protease are mixed evenly, the mass ratio of 3-methylthiopropanol, alkaline protease, neutral protease and oyster juice is 3:0.01:0.005:5, and the stirring speed of the mixed solution is 120r / min, Continue to stir, and add acetic acid dropwise while stirring; the drop rate of acetic acid is 3.5g / min, the mass ratio of 3-methylthiopropanol to acetic acid is 5:1, and w...

Embodiment 3

[0033] A kind of embodiment of the preparation method of flavor oyster sauce among the present invention (referring to figure 1 ), including the following steps:

[0034]Stir oyster juice, white sugar, monosodium glutamate, edible salt, caramel color, I+G and yeast extract evenly, the quality of oyster juice, white sugar, monosodium glutamate, edible salt, caramel color, I+G, and yeast extract The ratio is 6: 12: 10: 10: 2: 1: 3 to obtain a semi-finished mixed solution, and heat it to 90°C and keep it warm for 10 minutes; when the above mixed solution is cooled to 50°C, add 3-methylthiopropanol, alkaline Protease and neutral protease are mixed evenly, the mass ratio of 3-methylthiopropanol, alkaline protease, neutral protease and oyster juice is 3:0.02:0.01:5, and the stirring speed of the mixed solution is 150r / min, Continue to stir, and add acetic acid dropwise while stirring; the drop rate of acetic acid is 5g / min, and the mass ratio of 3-methylthiopropanol to acetic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com