Drop product volume production device

A droplet volume and droplet technology, which is applied to laboratory appliances, laboratory containers, fluid controllers, etc., can solve the problems of low efficiency of the drawing structure, unsatisfactory use effect, and excessive force, etc., to overcome Quantity and efficiency bottlenecks, ensuring output, and avoiding the effects of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

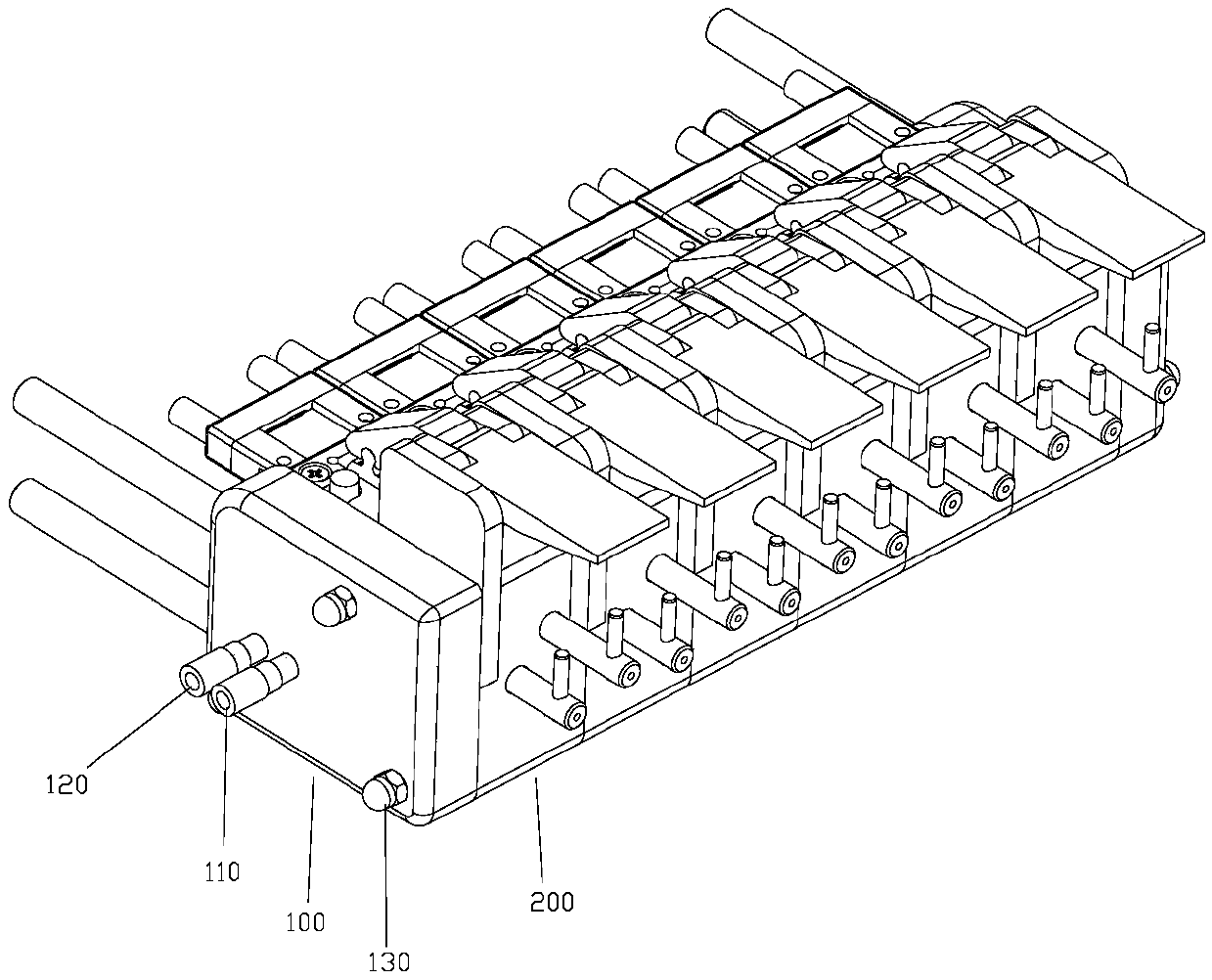

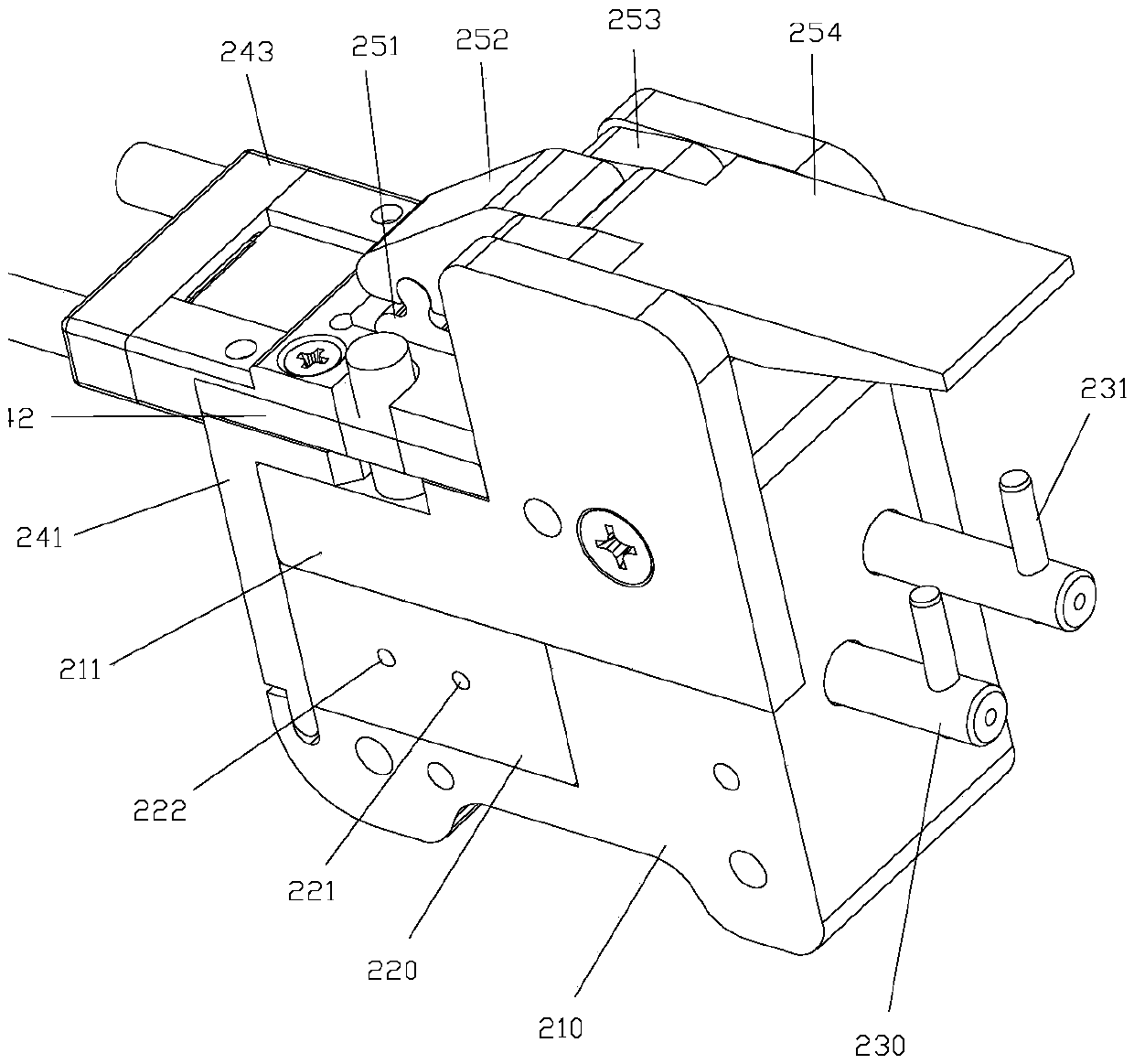

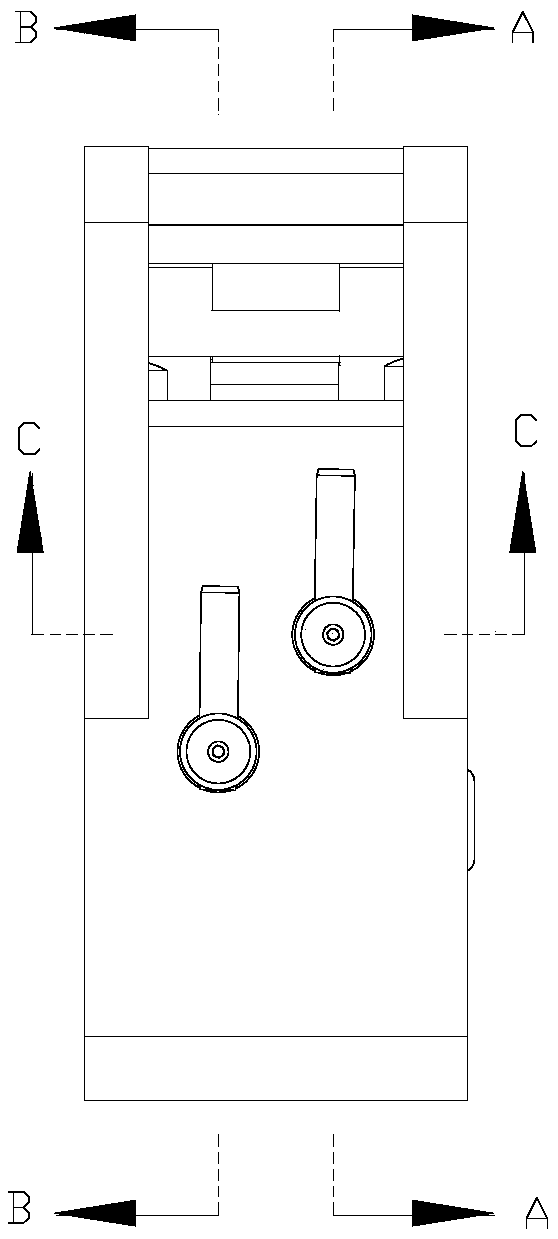

[0033] refer to figure 1 As shown, an embodiment of the droplet mass production device of the present invention is used to cooperate with a microfluidic chip to produce microdroplets. It includes six groups of droplet generating groups 200 connected in parallel and a pair of valve body brackets 100, wherein the pair of valve body brackets 100 are located on both sides of the droplet generating group 200, and the six groups of droplet generating groups are connected by the fixing member 130. 200 locks are fastened together. A water phase joint 110 and an oil phase joint 120 are screwed on a valve body support 100 for communicating with the external water phase and oil phase.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com