Electrical automatic equipment overhauling protection device

A technology for electrical automation and equipment maintenance. It is applied to the device for coating liquid on the surface, special surface, coating, etc. It can solve the problem of scratches and damage on the surface of the rubber roller, affect the service life of the rubber roller, and increase the operating cost of the factory. and other problems, to achieve the effect of not easy to delaminate, moderate viscosity, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

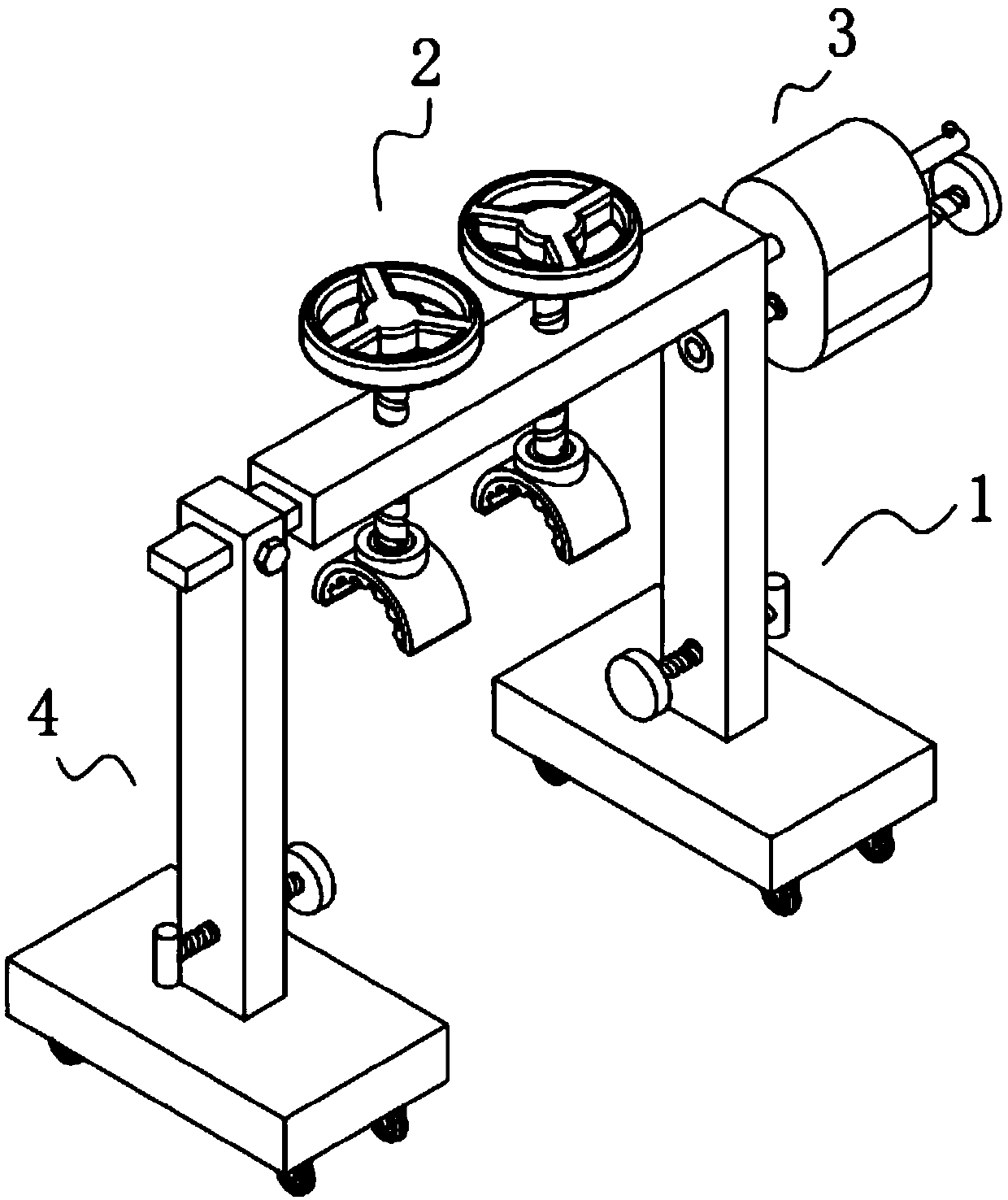

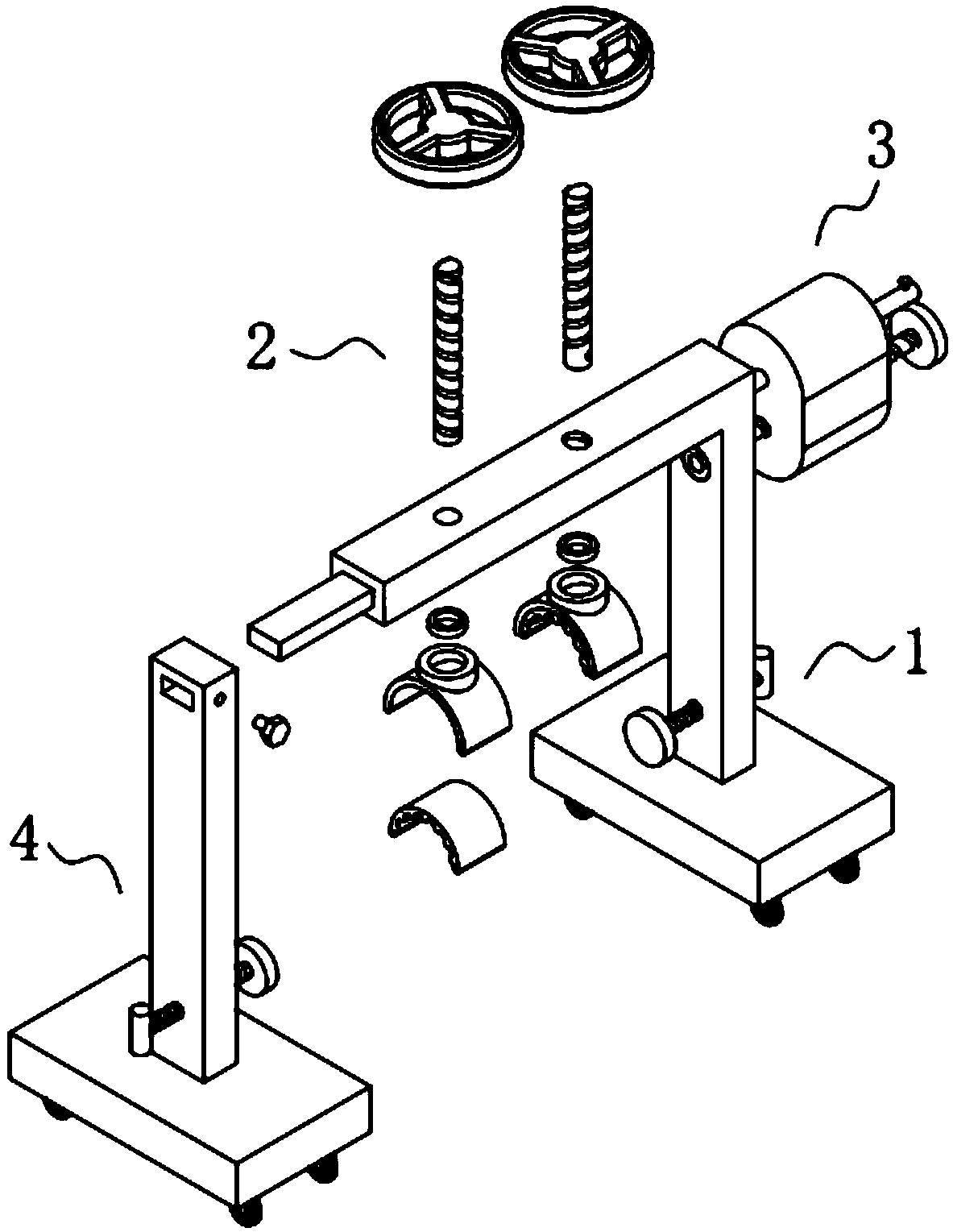

[0051] A maintenance protection device for electrical automation equipment, such as Figure 1-2 As shown, it includes a first support unit 1 and two groups of compression units 2, and the two groups of compression units 2 are installed on the upper part of the first support unit 1;

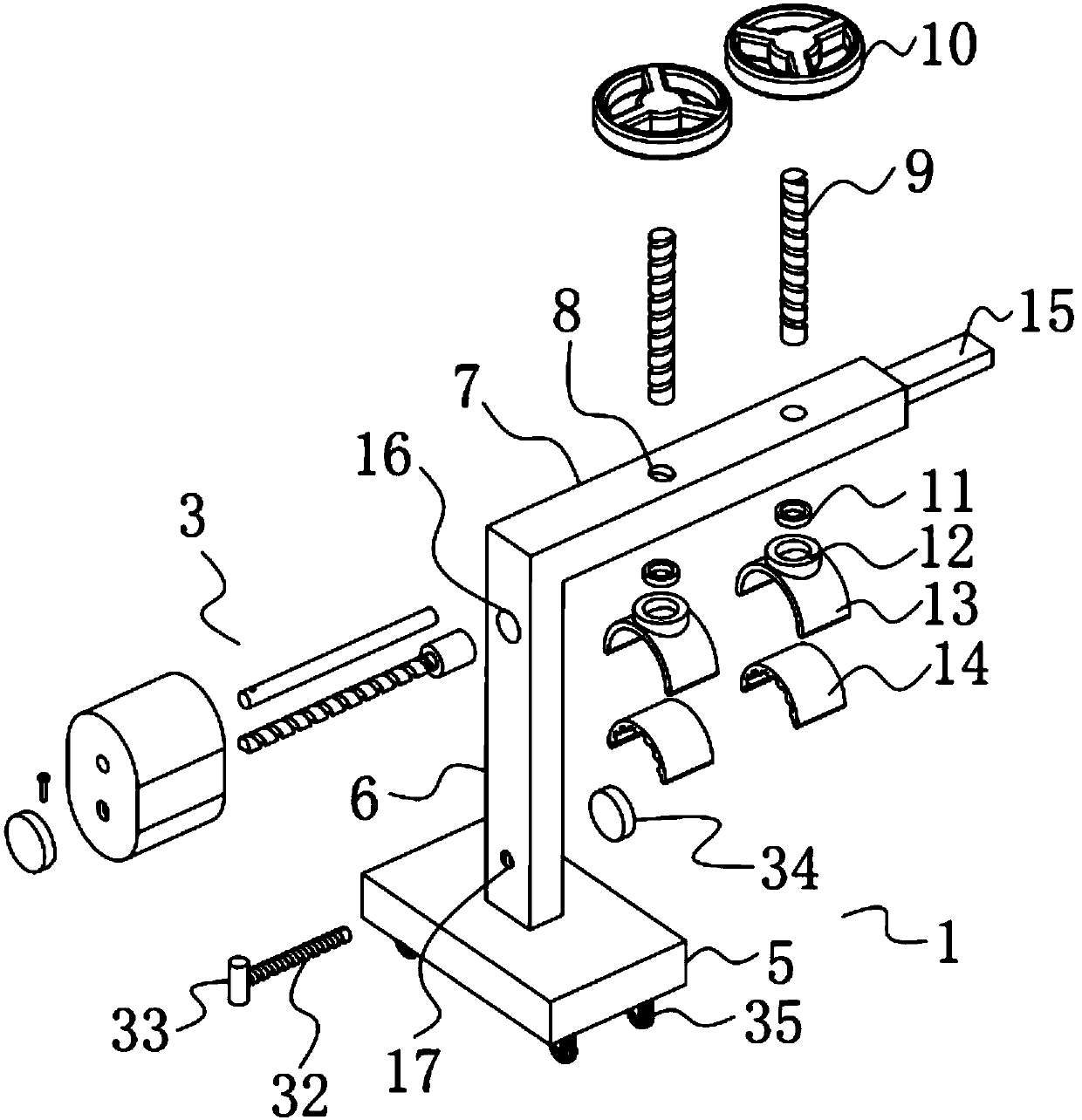

[0052] Such as image 3 As shown, the first support unit 1 includes a first base 5, a first support column 6 vertically and fixedly installed on the upper part of the first base 5, and a beam 7 fixedly installed on the upper end of the first support column 6, Two first installation holes 8 are symmetrically opened on the beam 7;

[0053] Such as image 3 As shown, each set of the pressing unit 2 includes a first threaded rod 9 vertically screwed inside the first mounting hole 8, a hand plate 10 fixedly installed on the upper end of the first threaded rod 9 and a The first rolling bearing 11 is fixedly set on the connection seat 12 outside the bottom end of the first threaded rod 9 and the arc-s...

Embodiment 2

[0068] The difference from Example 1 is that the surfaces of the first base 5 and the second base 26 are provided with a protective layer, and the protective layer is prepared by the following method:

[0069] Take the following raw materials and weigh them by weight: 20 parts of epoxy resin, 8 parts of mica powder, 11 parts of titanium dioxide powder, 12 parts of polytetrafluoroethylene, 12 parts of graphite powder, 8 parts of talcum powder, 2 parts of film-forming aids, 2 parts of agent, 1 part of defoamer and 30 parts of methanol;

[0070] S1. Add the weighed film-forming aid, accelerator, defoamer and methanol into the mixer and stir for 20min at a stirring speed of 600r / min to prepare a mixed solution;

[0071] S2, adding epoxy resin, mica powder, titanium dioxide powder, polytetrafluoroethylene, graphite powder and talcum powder into a pulverizer for pulverization to obtain a mixed powder material;

[0072] S3. Add the mixed solution prepared in step S1 and the mixed po...

Embodiment 3

[0081] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0082] Take the following raw materials and weigh them by weight: 25 parts of epoxy resin, 10 parts of mica powder, 13 parts of titanium dioxide powder, 14 parts of polytetrafluoroethylene, 14 parts of graphite powder, 9 parts of talcum powder, 3 parts of film-forming aids, 3 parts of agent, 2 parts of defoamer and 35 parts of methanol;

[0083] S1. Add the weighed film-forming aid, accelerator, defoamer and methanol into the mixer and stir for 25min at a stirring speed of 700r / min to prepare a mixed solution;

[0084] S2, adding epoxy resin, mica powder, titanium dioxide powder, polytetrafluoroethylene, graphite powder and talcum powder into a pulverizer for pulverization to obtain a mixed powder material;

[0085] S3. Add the mixed solution prepared in step S1 and the mixed powder material prepared in step S2 to the reactor and stir for 25 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com