Method for spraying EnSone ceramic on surface of heat dissipation strip of PTC heater

A technology of surface spraying and heat dissipation strips, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. It can solve problems such as damage to the quality of aluminum sheets, and achieve the effect of ensuring adhesion quality and long-term work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

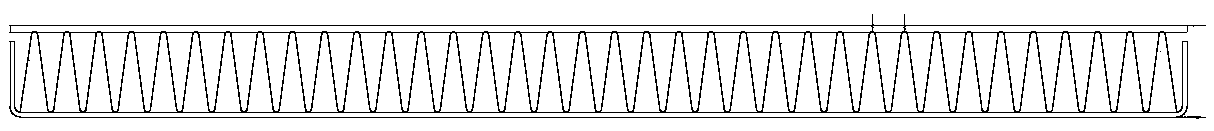

[0008] The typical structure of the PTC heater cooling strip is shown in the figure. The overall dimensions are basically the same, but the lengths are different. Its main structure is made of aluminum alloy plate, which is relatively thin aluminum plate, which is easy to deform after being stressed. Therefore, this factor needs to be considered in the surface spraying process.

[0009] 1. Surface roughening----choose No. 60-100, such as No. 80 corundum, to sandblast the heat dissipation strip under appropriate air pressure. The surface roughness is about Ra10μm, which is the best. .

[0010] 2. Cleaning the surface and preheating - degrease the surface of the heat dissipation strip after sandblasting with hot water, dry it with hot air and adjust the surface temperature of the aluminum strip to 30-35°C.

[0011] 3. Spraying "liquid ceramics" --- choose the appropriate spraying method [manual spraying or automatic spraying], and spray "liquid ceramics" on the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com