A method for correcting the overall flatness of a sheet welding flame tube eddy current device

A correction method and eddy current device technology, applied in the field of sheet metal welding, can solve the problems of unstable flame cylinder quality, large welding deformation of multi-layer thin-walled sheet metal parts, large flatness of the eddy current device, etc., and achieve the overall flatness and eddy current. Reliable control of the position of the device, improving the processing efficiency and quality, and reducing the effect of the correction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

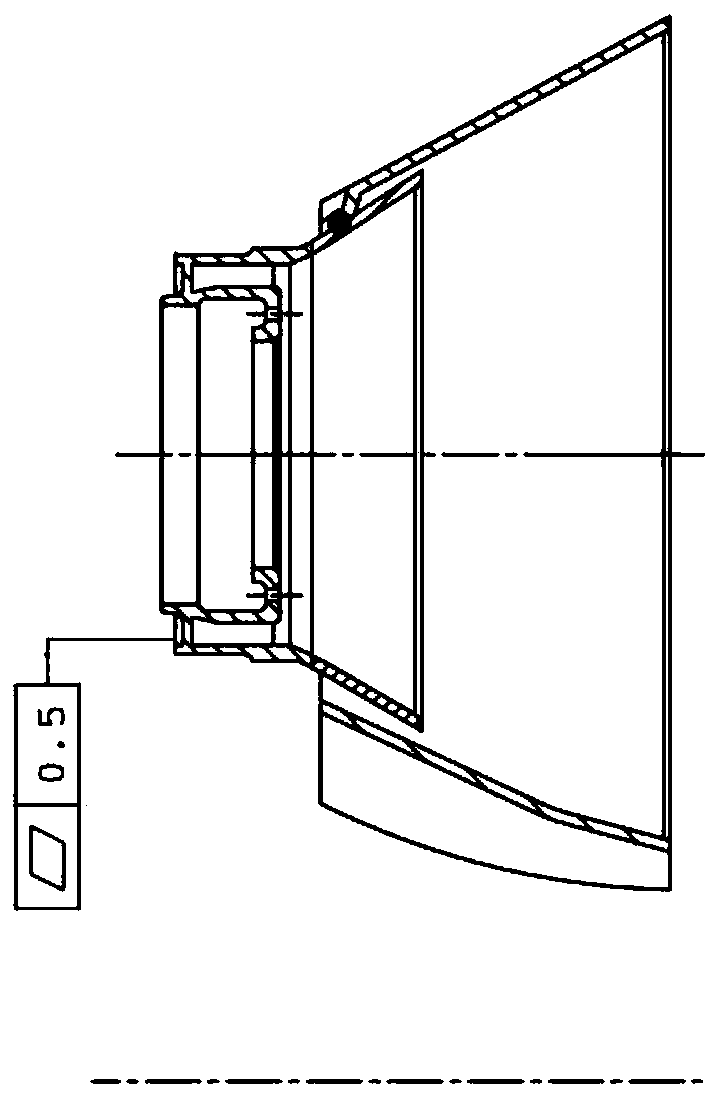

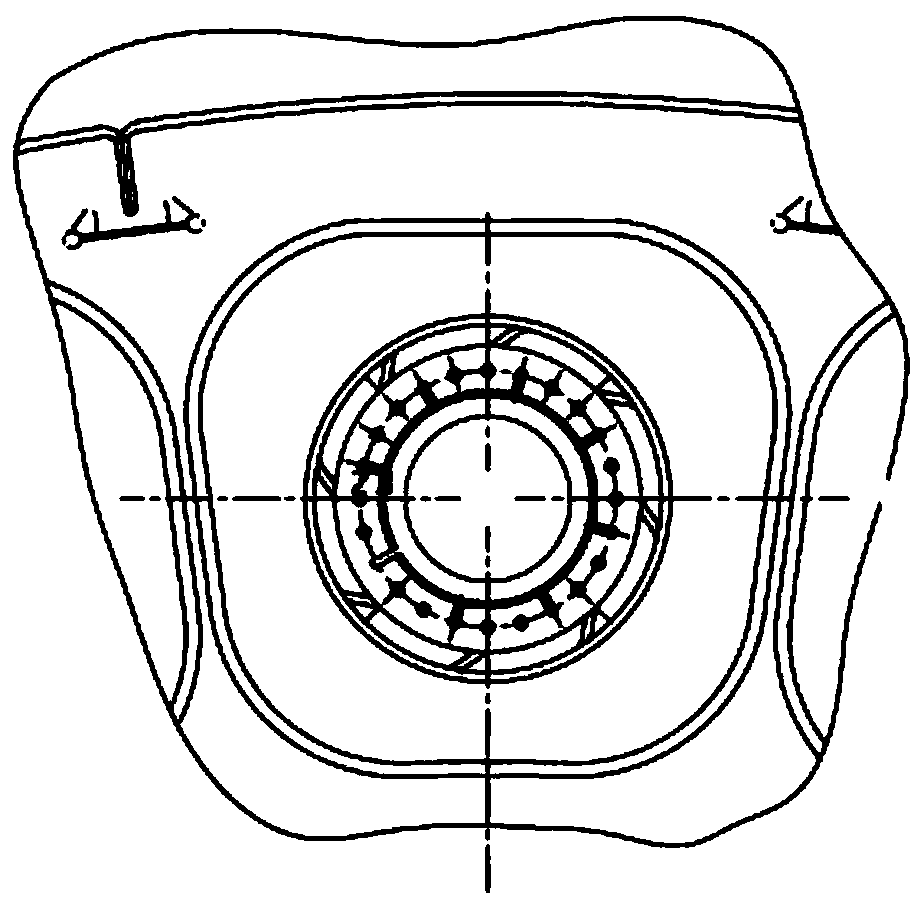

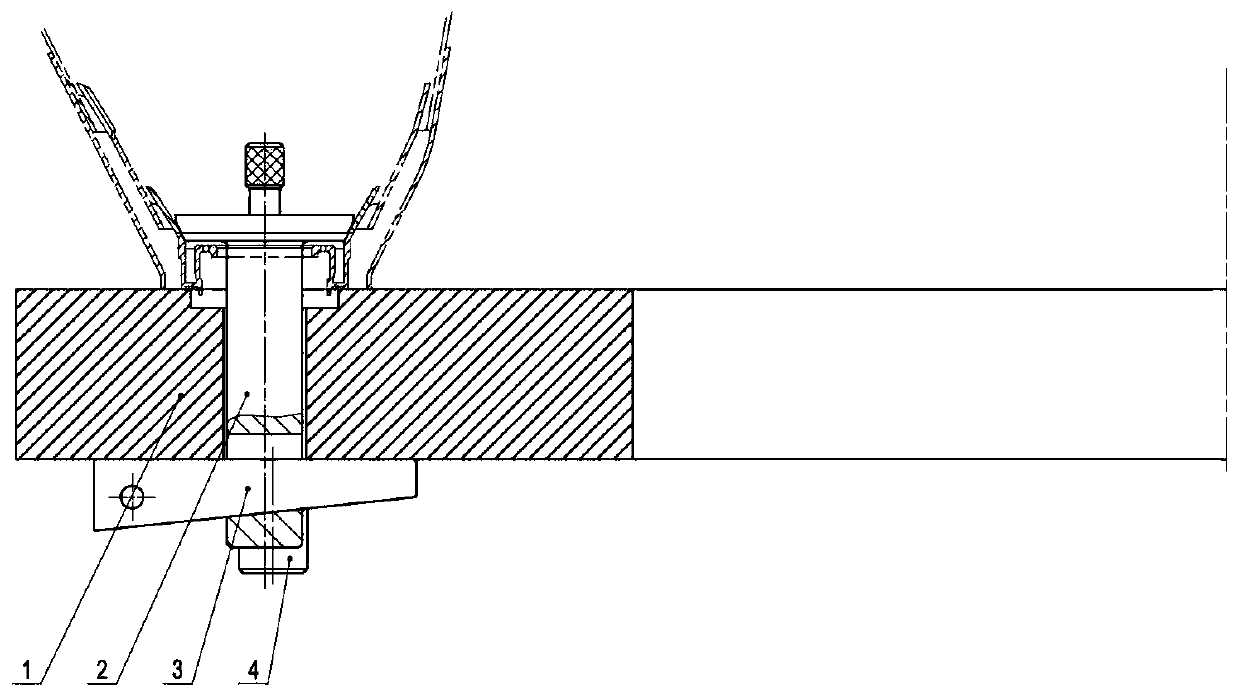

[0023] Such as image 3 As shown, the correction device includes a base 1, a gland 2, a wedge 3 and a foot 4; the base 1 is a ring whose upper and lower end faces are parallel, and there are a plurality of positioning holes passing through the upper and lower end faces on it. The positioning holes are There are two steps of stepped holes, the upper one is larger and the lower one is smaller, the larger hole matches the vortexer, the smaller hole matches the main body of the gland 2, the lower end surface of the base 1 is connected with the leg 4; the gland 2 includes a gland body whose outer diameter is smaller than the inner diameter of the positioning hole, and the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com