A Design Method for Alloy Melt Atomizer with Supersonic Laval Nozzle Structure

A Laval nozzle and design method technology, applied in design optimization/simulation, computer-aided design, instruments, etc., can solve the problems of insufficient system depth, less research on the flow field of supersonic nozzle atomization nozzle, etc., and achieve reduction The effect of energy loss, reduction of shock wave and turbulence, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

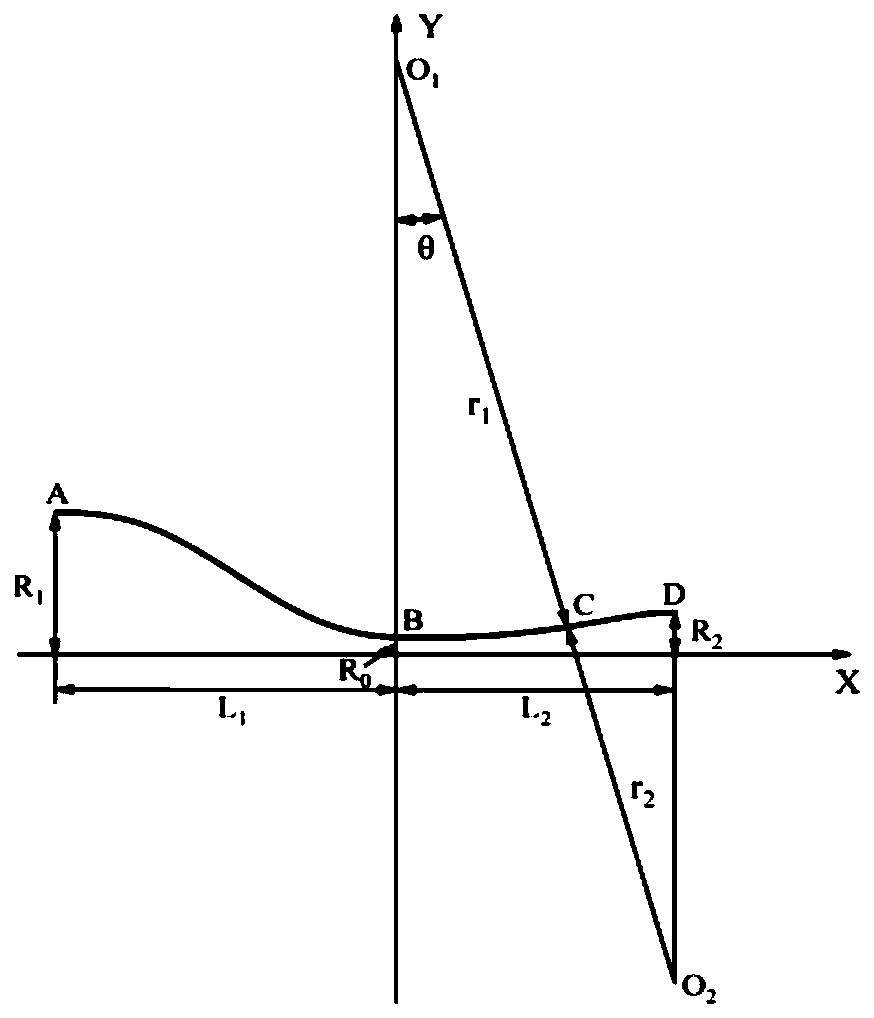

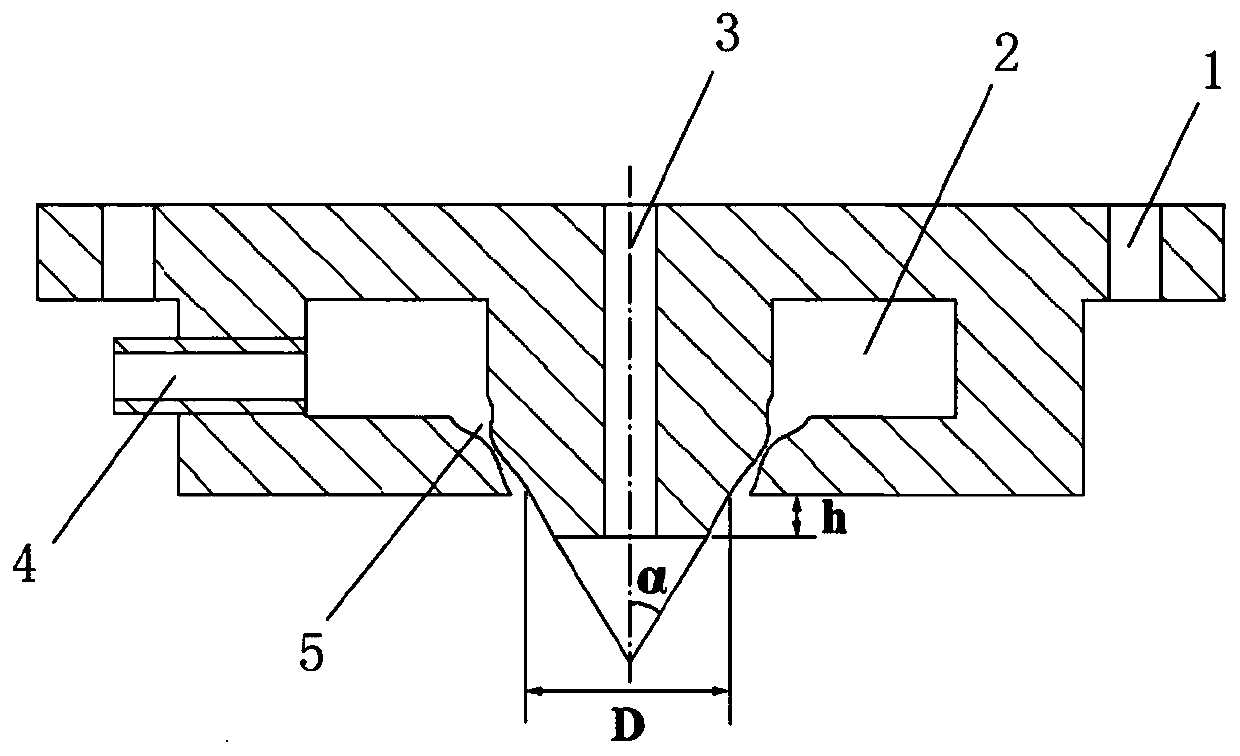

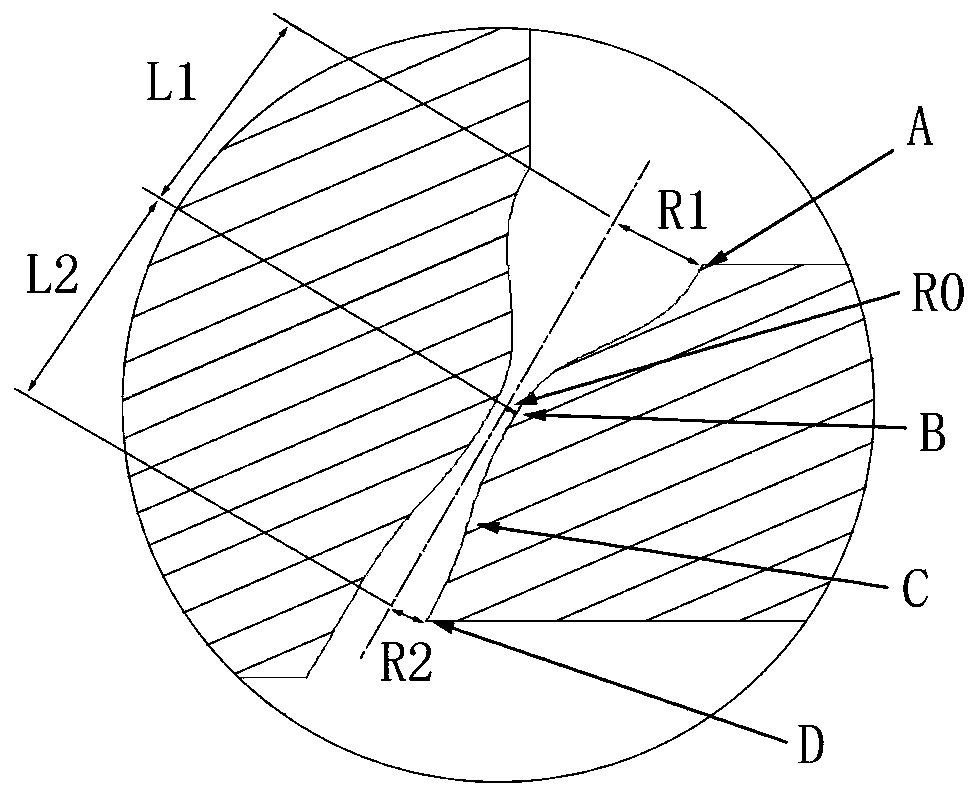

[0034] The simulation calculation found that when the atomization pressure is 1.7MPa, the gas does not expand after spraying when the atomization pressure is low, and when the atomization pressure increases to 3.2MPa, only a small expansion occurs after the gas exits. The increase of the atomizing gas pressure makes the velocity of the flow field gradually increase, and the maximum velocity increases from 615m / s to 674m / s, but the structure of the flow field is basically similar. Unlike ordinary gas nozzles, the Laval nozzle atomizer does not appear the so-called "closed vortex structure" when the pressure is increased. This is due to the special contraction-expansion structure of the Laval tube. The gas has been fully expanded and accelerated in the tube. The high-speed gas is ejected tangentially along the outlet, and no periodic expansion-compression waves are formed. When the atomization pressure is low, the static pressure in the recirculation area changes little and rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com