A kind of mid-wave infrared glass and its preparation process

A technology of infrared glass and preparation process, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of complex material processing, small range, poor stability, etc., achieve good chemical stability, low production cost, and use The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

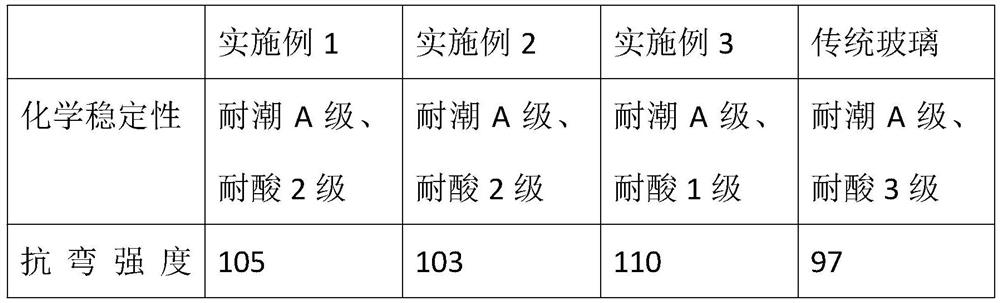

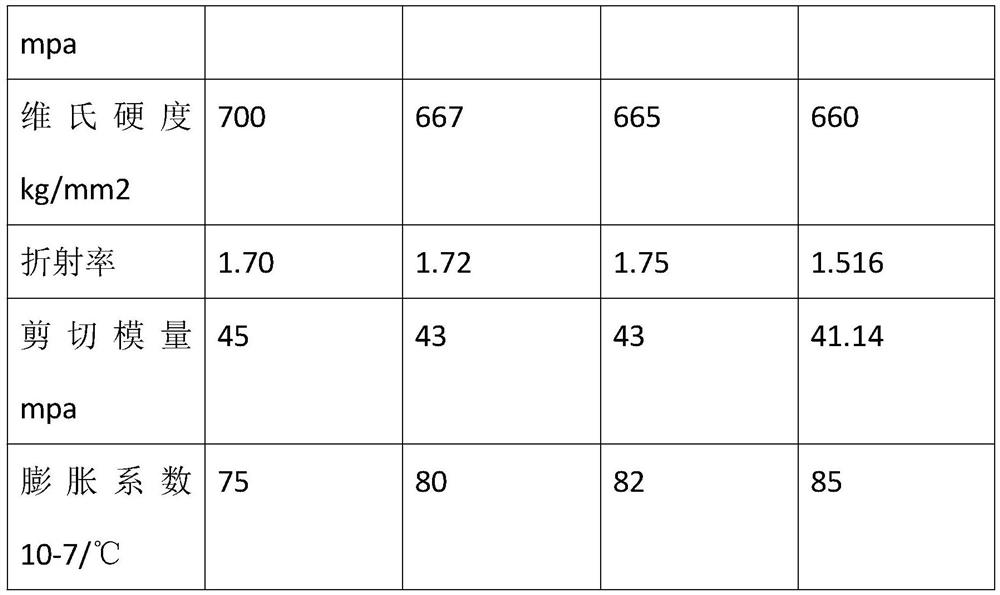

Examples

Embodiment 1

[0036] A medium-wave infrared glass, characterized in that it consists of the following components by mass percentage:

[0037] B 2 o 3 6-10%; GeO 70-81%, Bi 2 o 3 2~6%, La 2 o 3 2~4%, BaO 2~5%, Sb 2 o 3 0.5-4%.

[0038] In some embodiments, it consists of the following components by mass percentage:

[0039] B 2 o 3 8%; GeO 81%, Bi 2 o 3 4%, La 2 o 3 3%, BaO 3%, Sb 2 o 3 3%.

[0040] A preparation process for mid-wave infrared glass, comprising the steps of:

[0041] (1) Ingredients melting stage: Stir the materials of the above components according to the ratio and evenly pour them into the crucible and continue to heat at 1380°C±10°C for 6-10 hours. 8 feedings are completed;

[0042] (2) Clarification stage: Control the temperature in the crucible at 1410°C±10°C and keep it warm for 6-8 hours. During this process, stirring and defoaming should be carried out, and the stirring is divided into four times. The specific stirring speed is 60 rpm, 30 rp...

Embodiment 2

[0053] A medium-wave infrared glass, characterized in that it consists of the following components by mass percentage:

[0054] B 2 o 3 6-10%; GeO 70-81%, Bi 2 o 3 2~6%, La 2 o 3 2~4%, BaO 2~5%, Sb 2 o 3 0.5-4%.

[0055] In some embodiments, it consists of the following components by mass percentage:

[0056] B 2 o 3 8%; GeO 81%, Bi 2 o 3 4%, La 2 o 3 3%, BaO 3%, Sb 2 o 3 3%.

[0057] A preparation process for mid-wave infrared glass, comprising the steps of:

[0058] (1) Ingredients melting stage: Stir the materials of the above components according to the ratio and evenly pour them into the crucible and continue to heat at 1380°C±10°C for 6-10 hours. 8 feedings are completed;

[0059] (2) Clarification stage: Control the temperature in the crucible at 1410°C±10°C and keep it warm for 6-8 hours. During this process, stirring and defoaming should be carried out, and the stirring is divided into four times. The specific stirring speed is 60 rpm, 30 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com