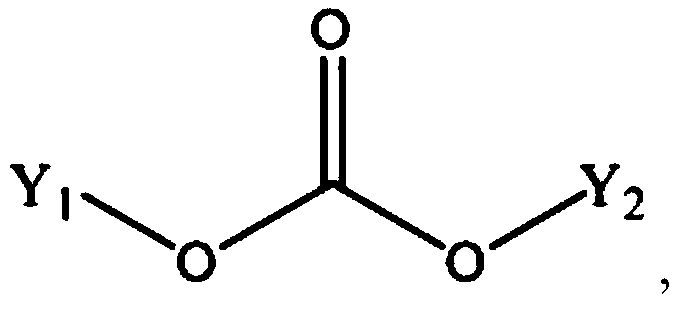

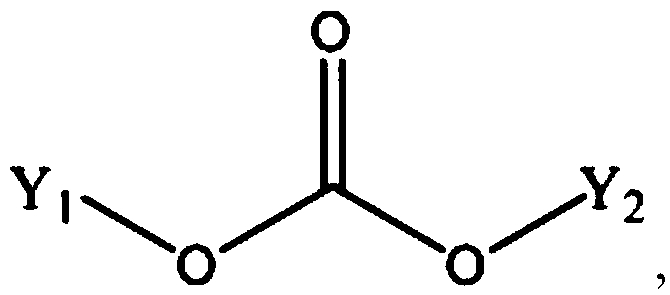

Preparation method of hydrocarbyl fluoroalkyl asymmetric chain carbonate

A technology of hydrocarbyl fluoroalkyl, chain carbonate, applied in the preparation of organic carbonate, electrochemical generator, organic chemistry, etc., can solve the problems of low yield, complicated synthesis steps, high toxicity of raw materials, etc. The effect of high rate, safe and easy-to-obtain raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

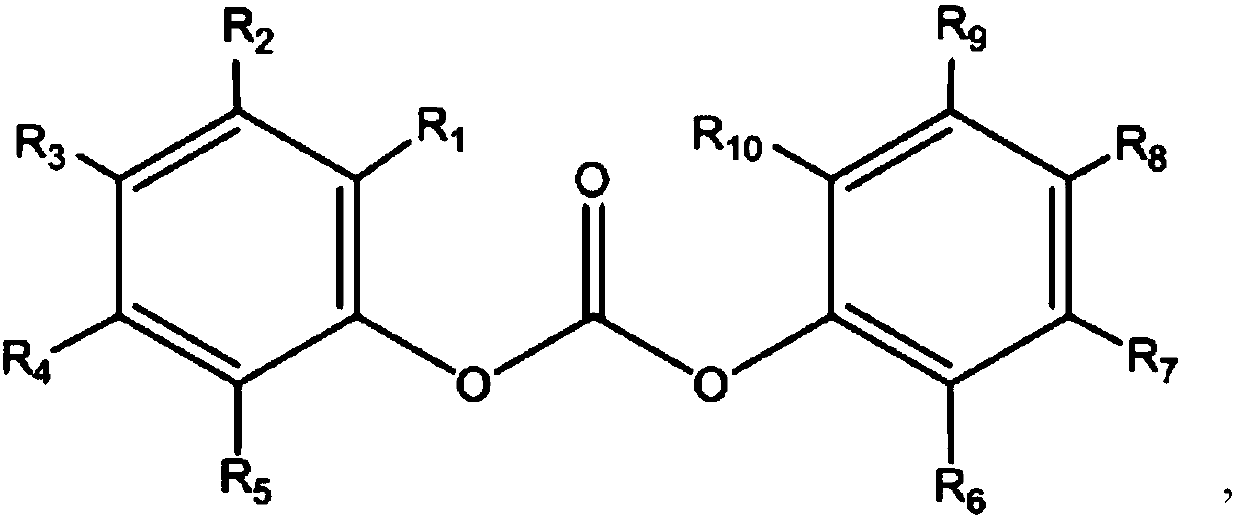

Method used

Image

Examples

Embodiment 1

[0034] Add 1980g of 2,2,3,3-tetrafluoropropanol, 2282g of phenyl-p-methylphenyl carbonate, and 250g of sodium carbonate into the reaction kettle, stir and raise the temperature to 68℃, react for 3h, then add 320g of methanol and continue to keep warm After 12h, after the heat preservation is completed, it is transferred to the distillation kettle for atmospheric distillation to obtain 1615 g of methyl tetrafluoropropyl carbonate with a yield of 85.1%. After testing, the purity of the obtained methyl tetrafluoropropyl carbonate is 99.91%, and the moisture content is 56 ppm.

example 2

[0036] Put 3680 g of anhydrous ethanol, 3042 g of bis(o-chlorophenyl) carbonate, and 600 g of solid sodium ethoxide into the reaction kettle, stir and raise the temperature to 78° C., react for 2 hours, and then add 2562 g of 4.4.4-trifluorobutanol. After the dripping is completed, the temperature is kept for 8 hours. After the temperature is completed, it is transferred to the rectification kettle for atmospheric distillation to obtain 1621 g of ethyl tetrafluorobutyl carbonate with a yield of 81.0%. After testing, the purity of the obtained ethyl tetrafluorobutyl carbonate is 99.94%, and the moisture content is 30 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com