Method for preparing phenolic resin microspheres by adopting imidazole binuclear alkaline functionalized ionic liquid as catalyst

A technology of ionic liquid and phenolic resin, which is applied in the field of preparing phenolic resin microspheres, can solve the problems of low yield, long time consumption, and low catalyst activity, and achieve high yield, improved alkali strength distribution, and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

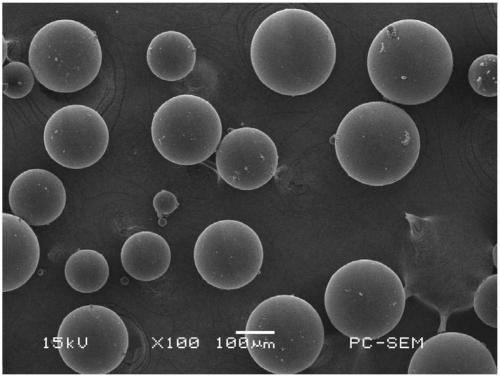

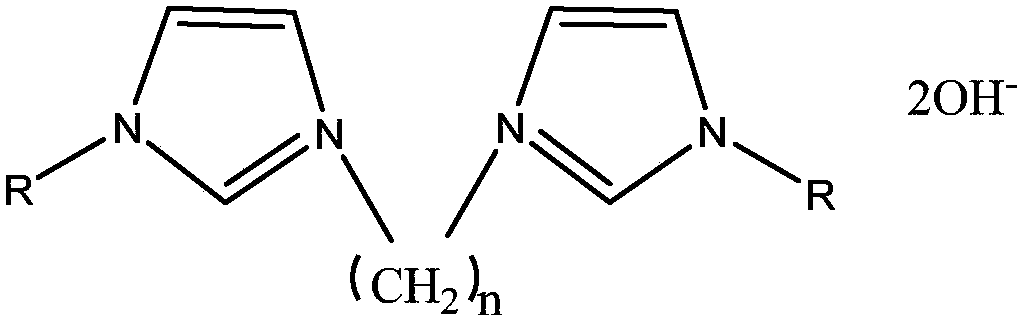

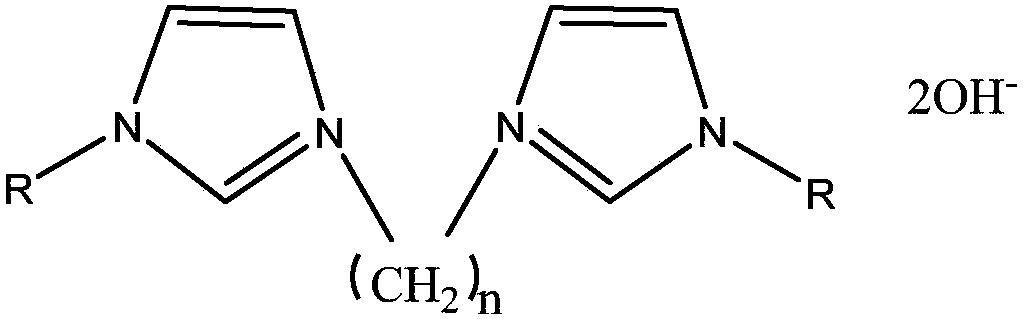

[0024] Phenol and formaldehyde are used as raw material monomers. First, prepare a 6.5wt% polyvinyl alcohol solution, pour it into a 1L reactor, heat it to 70°C, then add phenol and formaldehyde with a molar ratio of 1:1.6, and add 0.9wt% imidazole dinuclear alkaline Functionalized ionic liquid catalyst (1) and 500ml deionized water, at the same temperature, reacted for 4h at a stirring speed of 150r / min, then changed the stirring speed to 300r / min, added 6.0wt% hexamethylenetetramine, And slowly raise the temperature to 90°C, and finally react at this stirring speed and temperature for 4h to terminate. After the reaction temperature drops to normal temperature, unload the material, wash repeatedly with 70°C deionized water until the upper layer solution is clear, then filter and dry at 110°C for a period of time to obtain phenolic resin microspheres. After the filtrate is cooled to room temperature, the imidazole-based binuclear basic functionalized ionic liquid and water ar...

Embodiment 2

[0026] Phenol and formaldehyde are used as raw material monomers. First, prepare a 6.5wt% polyvinyl alcohol solution, pour it into a 1L reactor, heat it to 80°C, then add resorcinol and formaldehyde with a molar ratio of 1:1.8, and add 0.5wt% imidazole dinuclear Alkaline functionalized ionic liquid catalyst (2) and 500ml deionized water, at the same temperature, react at 150r / min stirring speed for 4h, then change the stirring speed to 300r / min, add 6.0wt% hexamethylene tetra Amine, and slowly warming up to 95 ° C, and finally reacted at this stirring speed and temperature for 4h to terminate. After the reaction temperature drops to normal temperature, unload the material, wash repeatedly with 70°C deionized water until the upper layer solution is clear, then filter and dry at 110°C for a period of time to obtain phenolic resin microspheres. After the filtrate is cooled to room temperature, the imidazole-based binuclear basic functionalized ionic liquid and water are automati...

Embodiment 3

[0028] Phenol and formaldehyde are used as raw material monomers. First, prepare a 6.5wt% polyvinyl alcohol solution, pour it into a 1L reactor, heat it to 85°C, then add p-cresol and formaldehyde with a molar ratio of 1:1.7, and add 0.3wt% imidazole at the same time The dual-nuclear alkaline functionalized ionic liquid catalyst (3) and 500ml of deionized water were reacted at the same temperature for 4 hours at a stirring speed of 150r / min, and then the stirring speed was changed to 300r / min, and 6.0wt% hexamethylene was added Tetramine, and slowly warming up to 100°C, and finally reacting at this stirring speed and temperature for 4h to terminate. After the reaction temperature drops to normal temperature, unload the material, wash repeatedly with 70°C deionized water until the upper layer solution is clear, then filter and dry at 110°C for a period of time to obtain phenolic resin microspheres. After the filtrate is cooled to room temperature, the imidazole-based binuclear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com