Preparation method of tamarind polysaccharide gel

A technology for tamarind polysaccharide gum and tamarind polysaccharide, which is applied in the field of polysaccharide gel, can solve the problems of not utilizing tamarind polysaccharide gel and the like, and achieve the effects of simple and fast preparation process, low cost and complicated preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

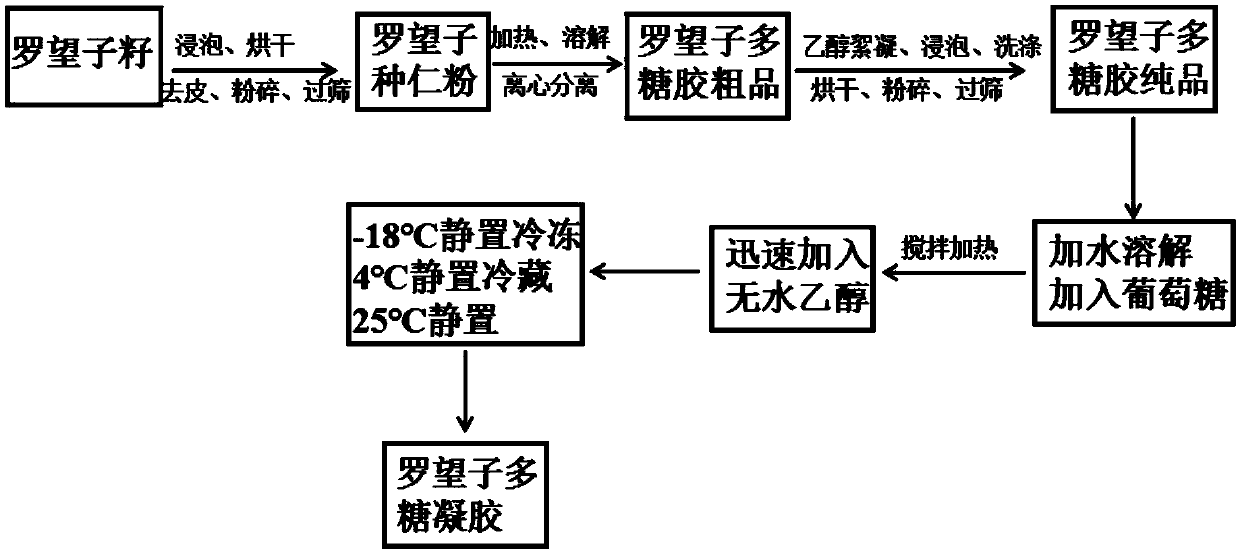

[0038] (1) Preparation of tamarind seed kernel powder: soak tamarind seed seed in hot water, drain water, dry, peel off seed coat, pulverize, sieve, obtain tamarind seed kernel powder;

[0039] (2) Extraction of tamarind polysaccharide gum: Dissolve the tamarind seed kernel powder in hot water, stir at a constant temperature, centrifuge at a speed of 6000-12000 rpm after cooling, and collect the supernatant; if the centrifugal speed is less than 6000 rpm, The sedimentation of protein and impurities is not complete, and the centrifugation speed higher than 9000rpm will cause some tamarind polysaccharide gums to settle, reducing the extraction rate of tamarind polysaccharide gums;

[0040] (3) Purification of tamarind polysaccharide gum: add the same volume of absolute ethanol to the supernatant, stir, let stand, take out the precipitate and add absolute ethanol to soak and wash several times, remove the solvent, and obtain purified tamarind polysaccharide gum;

[0041] (4) Pul...

Embodiment 1

[0056] (1) Preparation of tamarind seed kernel powder: Soak tamarind seed and hot water for 24 hours according to the mass ratio of 1:2, drain the water, dry at 100°C for 48 hours, peel off the seed coat, crush it with a pulverizer, and pass through a 60-mesh sieve ,spare;

[0057] (2) Extraction of tamarind polysaccharide gum: Weigh 10g of tamarind seed kernel powder, put it into hot water at 85°C at a mass ratio of 1:50, stir with a magnetic stirrer at constant temperature for 50min, and cool it at a speed of 9000rpm Centrifuge and collect the supernatant;

[0058] (3) Purification of tamarind polysaccharide gum: add the same volume of absolute ethanol to the supernatant, fully stir it with a magnetic stirrer for 30 minutes, then let it stand still, take out the precipitate and add 50mL ethanol to soak and wash with a volume ratio of 1:2, gently Squeeze the precipitate, remove the solvent, and repeat the washing 4 times to obtain the purified tamarind polysaccharide gum. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

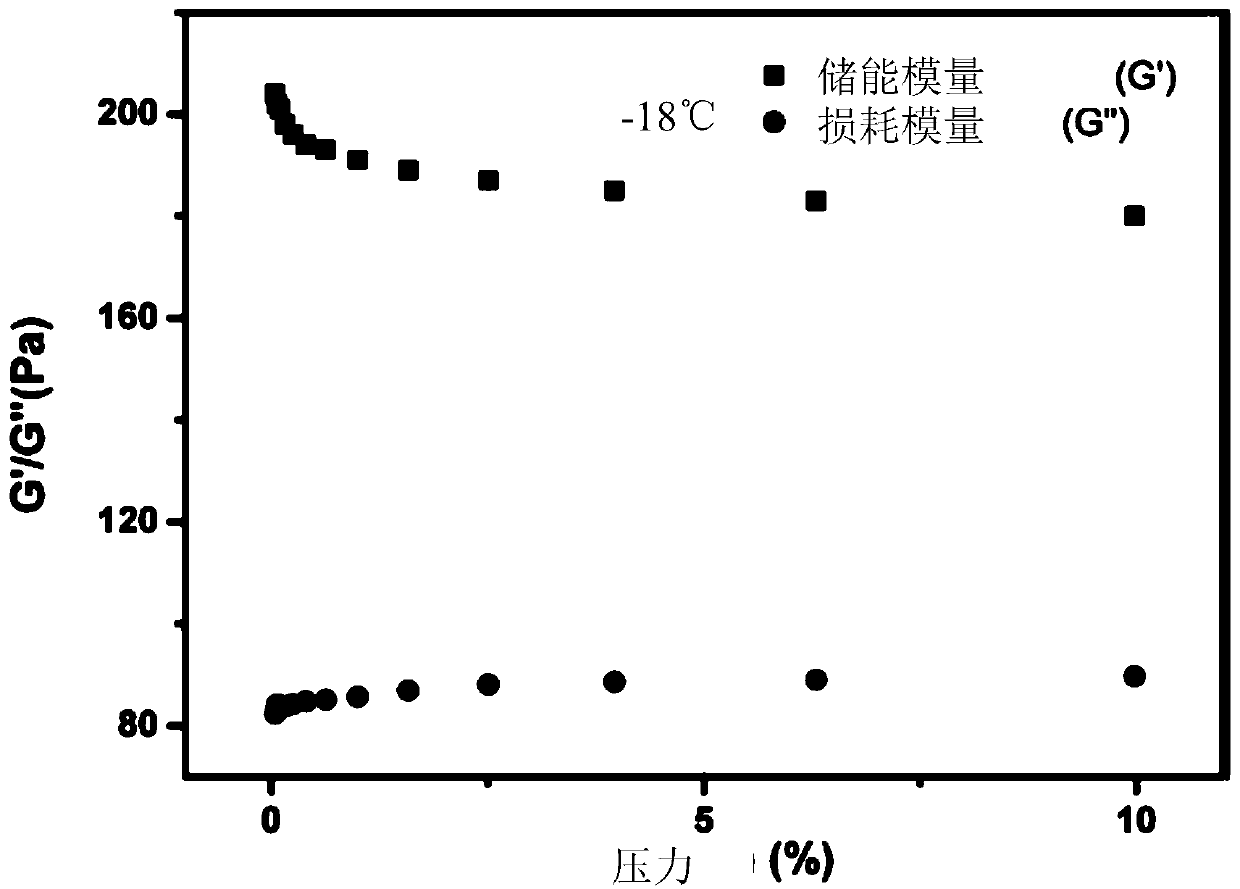

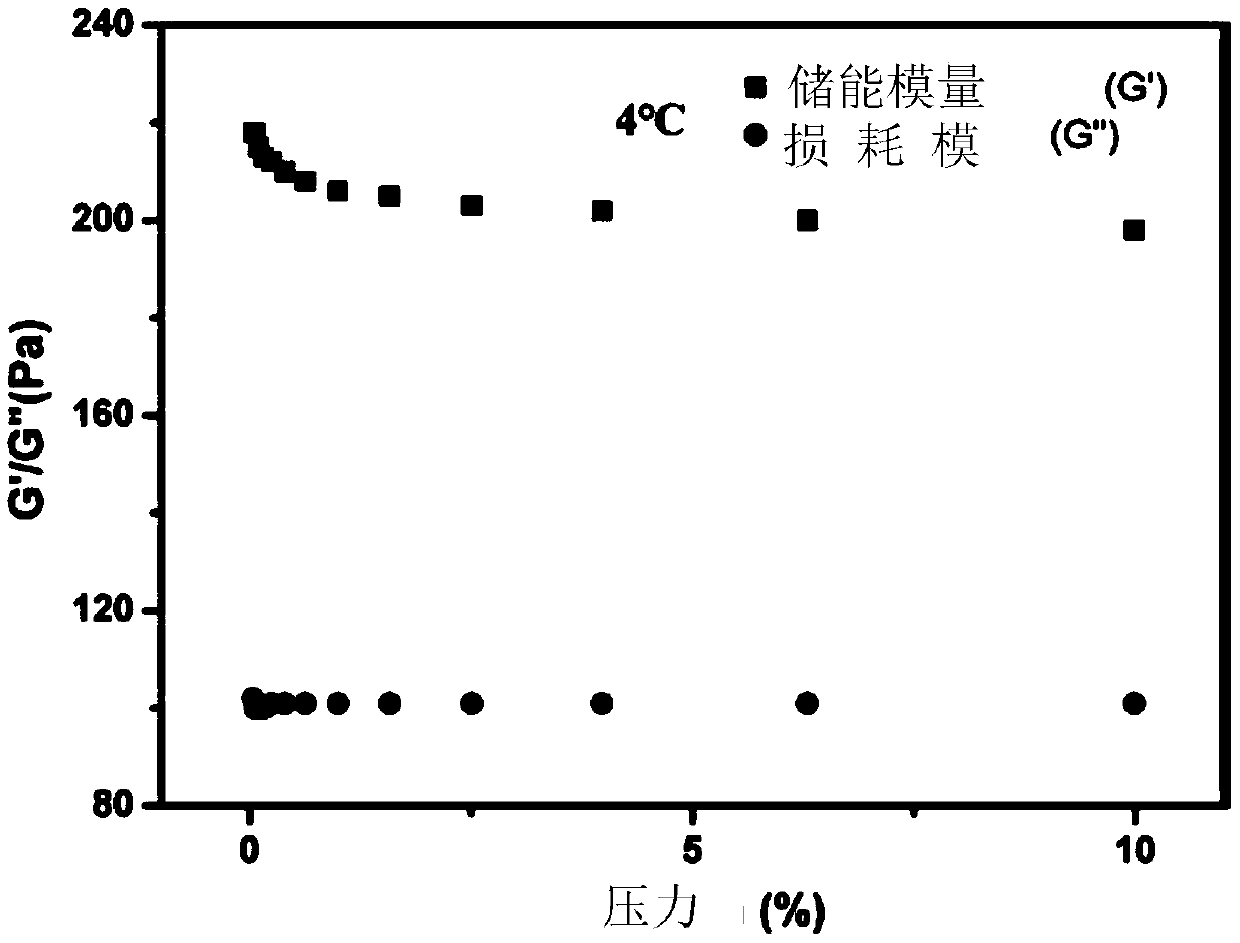

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com