Algae fiber facial mask base fabric and preparation method thereof

A technology of seaweed fiber and calcium alginate fiber, which is applied in fiber treatment, plant fiber, non-woven fabrics, etc., can solve the problems of cumbersome and complicated processes, improve subcutaneous tissue damage, repair skin damage, and moisturize and not greasy skin Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

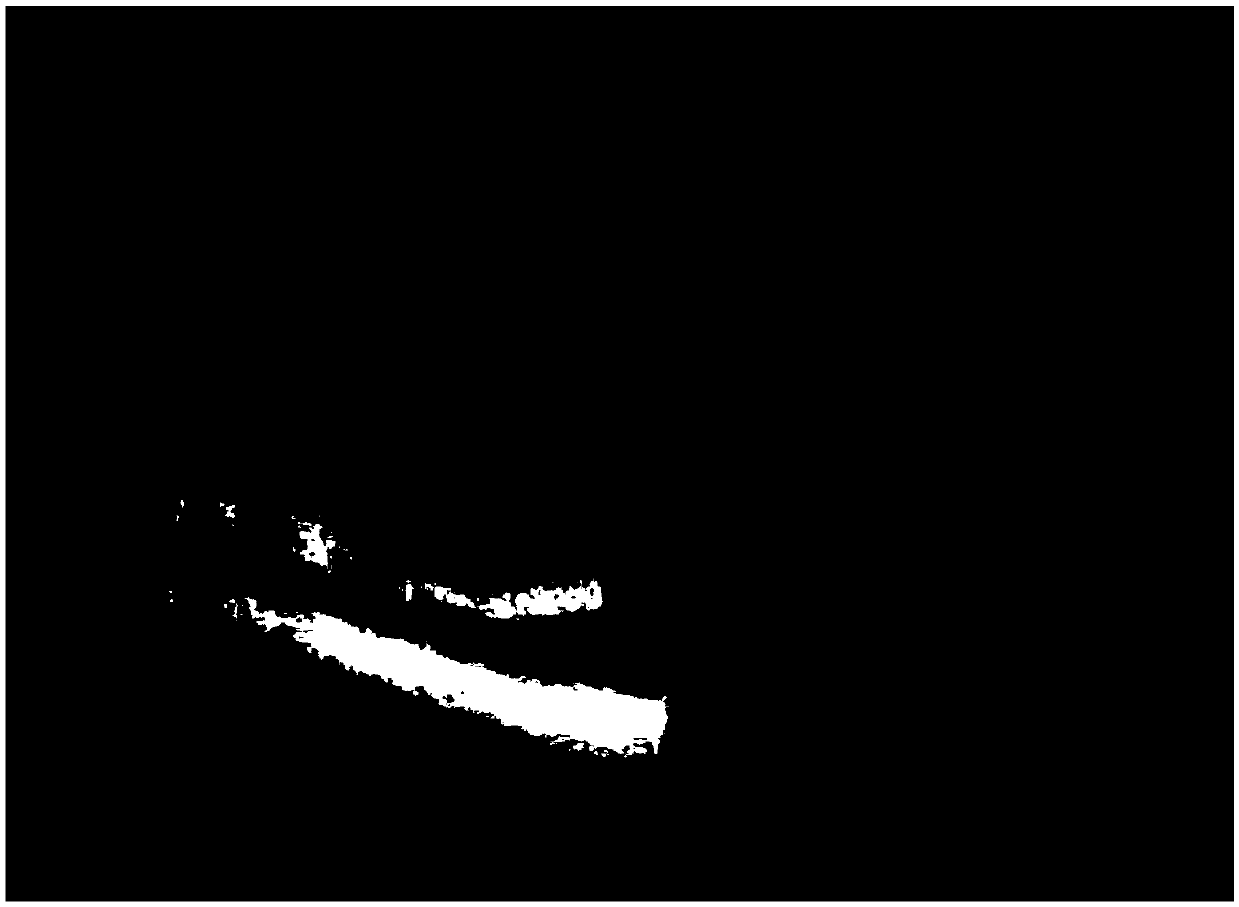

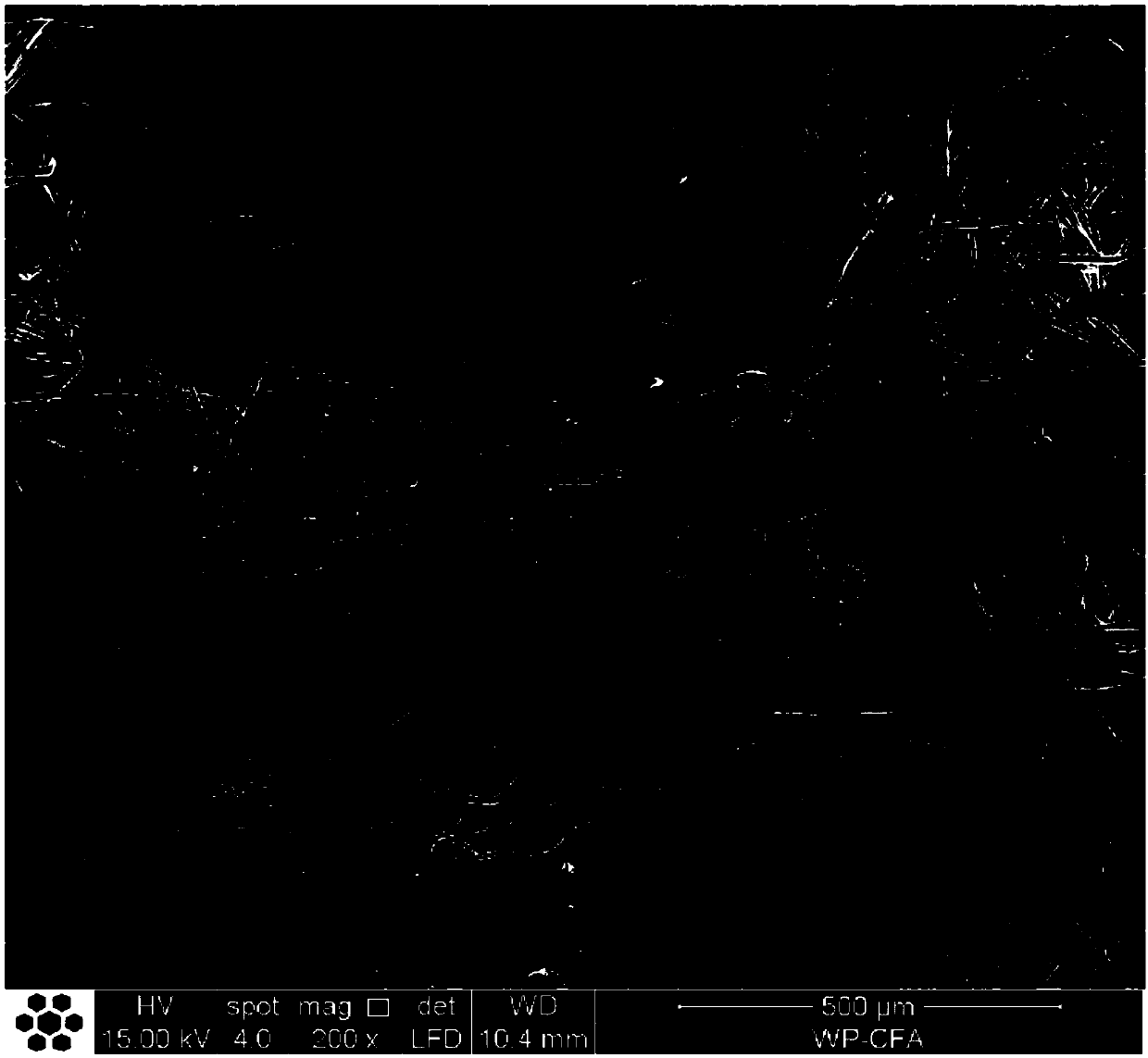

Image

Examples

Embodiment 1

[0034] The seaweed fiber facial mask base cloth is composed of the following components according to mass percentage: 80% carboxymethyl cellulose fiber, 15% calcium alginate fiber and 5% sodium alginate.

[0035] The preparation steps of above-mentioned seaweed fiber mask base cloth are as follows:

[0036] (1) Weigh the raw materials in proportion for later use. Carboxymethyl cellulose fibers and calcium alginate fibers are preliminarily opened and mixed by hand, and then opened with an opener to open the fibers from the original compacted state. Relaxed state;

[0037] (2) mixing the carboxymethyl cellulose fiber and the calcium alginate fiber through step (1), and further opening after mixing;

[0038] (3) Comb the mixed fibers obtained in step (2) into a web, and then perform hydroentanglement processing with a hydroentanglement machine, and spray high-pressure fine water flow onto the fiber web, and the fibers will entangle with each other during the process, so that the...

Embodiment 2

[0042] The seaweed fiber facial mask base cloth is composed of the following components according to mass percentage: 75% carboxymethyl cellulose fiber, 15% calcium alginate fiber and 10% sodium alginate.

[0043] The preparation method of above-mentioned seaweed fiber mask base cloth, concrete steps are as follows:

[0044] (1) Weigh the raw materials in proportion for later use. Carboxymethyl cellulose fibers and calcium alginate fibers are preliminarily opened and mixed by hand, and then opened with an opener to open the fibers from the original compacted state. Relaxed state;

[0045] (2) mixing the carboxymethyl cellulose fiber and the calcium alginate fiber through step (1), and further opening after mixing;

[0046](3) Comb the mixed fibers obtained in step (2) into a web, and then perform hydroentanglement processing with a hydroentanglement machine, and spray high-pressure fine water flow onto the fiber web, and the fibers will entangle with each other during the pro...

Embodiment 3

[0050] The seaweed fiber facial mask base cloth is composed of the following components by mass percentage: 77% carboxymethyl cellulose fiber, 17% calcium alginate fiber and 6% sodium alginate.

[0051] The preparation method of above-mentioned seaweed fiber mask base cloth, concrete steps are as follows:

[0052] (1) Weigh the raw materials in proportion for later use. Carboxymethyl cellulose fibers and calcium alginate fibers are preliminarily opened and mixed by hand, and then opened with an opener to open the fibers from the original compacted state. Relaxed state;

[0053] (2) mixing the carboxymethyl cellulose fiber and the calcium alginate fiber through step (1), and further opening after mixing;

[0054] (3) Comb the mixed fibers obtained in step (2) into a web, and then perform hydroentanglement processing with a hydroentanglement machine, and spray high-pressure fine water flow onto the fiber web, and the fibers will entangle with each other during the process, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com