Ultra-high performance concrete prefabricated hollow bridge deck slab with longitudinal and transverse ribs and construction method of ultra-high performance concrete prefabricated hollow bridge deck slab

An ultra-high performance, concrete technology, used in the manufacture of tools, bridges, bridge parts, etc., can solve the problems of low strength, large cross-section and self-heavy weight of bridge decks, and achieve easy and convenient construction, good mechanical properties, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

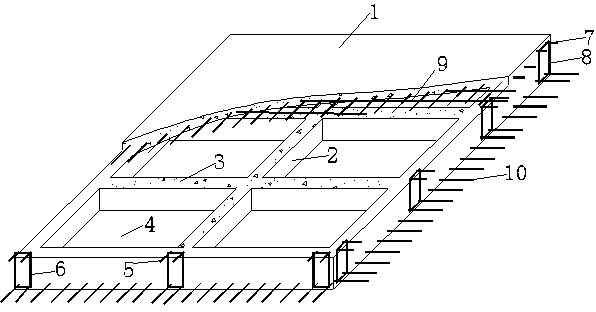

[0015] Such as figure 1 As shown, the ultra-high-performance concrete prefabricated hollow bridge deck with longitudinal and transverse ribs of the present invention includes a top plate 1, a bottom plate 4, and a beam rib intersecting vertically and horizontally between the top plate 1 and the bottom plate 4. The beam rib includes a longitudinal beam rib 2 and a cross beam rib 3 , the longitudinal beam ribs 2 and the cross beam ribs 3 intersect to form a hollow structure, and the top plate and the bottom plate are equipped with ordinary steel meshes made of ordinary steel bars horizontally and vertically, and the ordinary steel meshes are the roof steel mesh 9 and the bottom plate steel mesh 10, The beam rib is equipped with a prestressed steel mesh made of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com