Efficient, environment-friendly and low-cost preparation method for polyphenyl ether

A polyphenylene ether, low-cost technology, applied in the field of preparation of engineering material polyphenylene ether, can solve the problems of high cost, high toxicity, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

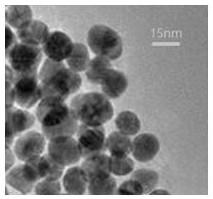

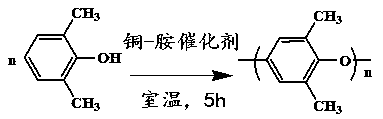

[0027] Put 2.23g (10mmol) of copper bromide into a PTFE-lined autoclave, add an appropriate amount of ethanol, mix well, cover the lid tightly, place in a muffle furnace, control the temperature at 200°C, and react for 18 hours . After the reaction is completed, take out the reaction kettle, cool to room temperature, vacuum filter under reduced pressure, wash with ethanol, and vacuum-dry the product obtained by suction filtration to obtain nano-cuprous bromide. Weigh nano-cuprous bromide (0.1g) into a four-necked flask, then add dimethyl n-butylamine (4mL), the molar ratio of nano-cuprous bromide and dimethyl n-butylamine is 1:50, The color becomes light yellow, then add 30ml of tetrahydrofuran as a solvent, the color turns to yellow-green, put the device on a magnetic stirrer, start stirring and feed oxygen for 5 minutes, then add 2.2ml of tetrahydrofuran to the four-necked flask 2,6-Xylenol (2.5g, 18mmol), continue to feed oxygen for 2 hours, after reacting for 4-5 hours, e...

Embodiment 2

[0029] According to the method and operation steps of Example 1, the process of introducing oxygen in Example 1 was changed to the process of introducing air to obtain 1.87 g of light yellow polyphenylene ether with a yield of 74.80%. It can be seen that replacing oxygen with air does not have much influence on the yield and quality of polyphenylene ether.

Embodiment 3

[0031] According to the method and operation steps of Example 2, the nano-sized cuprous bromide in Example 2 was changed to commercial cuprous bromide to obtain 1.03 g of light yellow polyphenylene ether with a yield of 41.20%. It can be seen that the catalytic activity of nano-sized cuprous bromide provided by the present invention is much higher than that of commercial cuprous bromide by adopting the process of feeding air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com