Environment-friendly durable composite foam material, as well as preparation method and application thereof

A composite foaming and durable technology, applied in applications, shoe soles, clothing, etc., can solve the problems of gas permeability, wear resistance, anti-slip performance, and poor compression deformation resistance, so as to reduce gas overflow rate and improve support , to meet the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

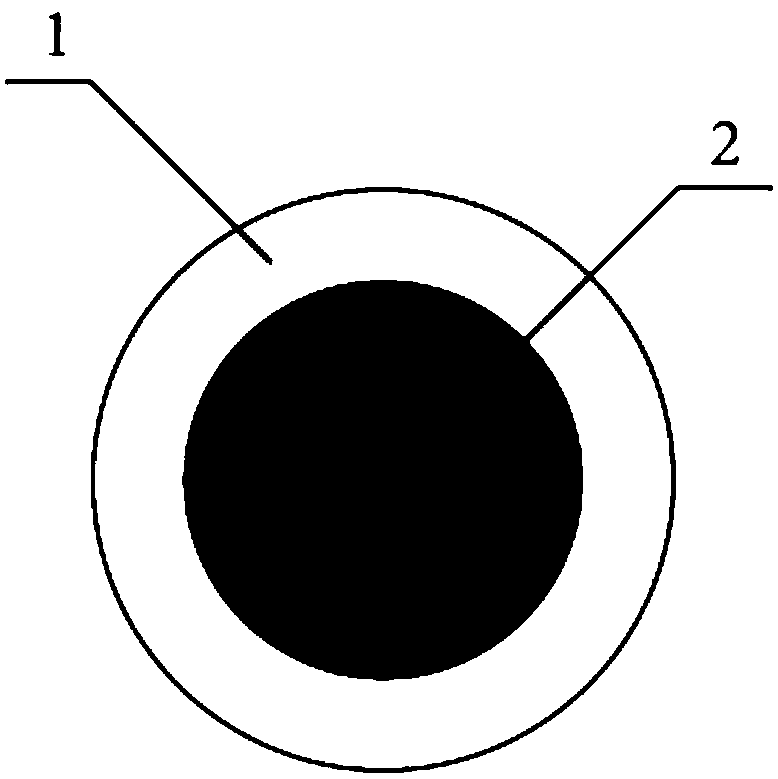

[0044] In a second aspect, the present invention provides a method for preparing the above-mentioned environmentally friendly and durable composite foam material, which specifically includes the following steps:

[0045] (1) Add the ethylene vinyl acetate copolymer, ethylene vinyl acetate rubber, ethylene-octene copolymer, filler, zinc oxide and zinc stearate in parts by mass into an internal mixer and knead for 3 to 5 minutes.

[0046] (2) Add the benzene-free crosslinking agent of the above mass parts into the internal mixer and continue mixing for 2 to 3 minutes;

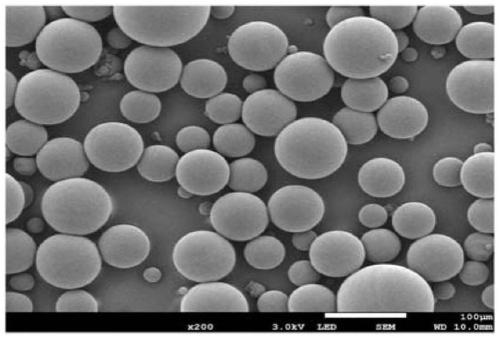

[0047] (3) Add the above-mentioned expandable microsphere foaming agent in parts by mass to the internal mixer and continue mixing for 2 to 3 minutes;

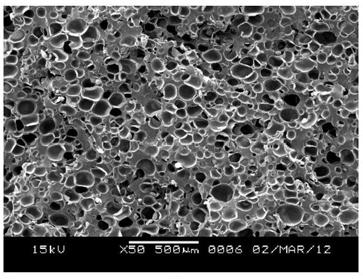

[0048] (4) Granulating the material obtained in step (3), followed by foam molding to obtain an environmentally friendly and durable composite foam material;

[0049] Wherein, in step (1) to step (3), the mixing temperature of the internal mixer is 90°C to 120°C...

Embodiment 1

[0063] The consumption of each raw material is as shown in Table 1 in the present embodiment.

[0064] The preparation method of the composite foam material in this embodiment is: use an internal mixer to mix the raw materials sequentially, the mixing temperature is 90°C-120°C, the rotating speed of the internal mixer rotor is 40-70 rpm, During the refining process, ethylene-vinyl acetate, ethylene-vinyl acetate rubber, ethylene-octene copolymer, zinc stearate, zinc oxide and fillers are first added to the internal mixer for mixing. The mixing time is 3 to 5 minutes, after mixing evenly, add the crosslinking agent, mix for 2 to 3 minutes, then add the expandable microsphere foaming agent, adjust the rotor speed of the internal mixer to 30 to 40 rpm, and mix for 2 to 3 minutes Discharging, granulation after banburying, followed by foam molding to obtain environmentally friendly and durable foam material pellets.

Embodiment 2 to Embodiment 7

[0066] The consumption of each raw material in embodiment 2 to embodiment 7 is as shown in table 2.

[0067] The preparation methods of the composite foam materials in Examples 2 to 7 are the same as those in Example 1, the only difference being that the dosage of each raw material is adjusted accordingly according to Table 2.

[0068] Table 2

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com