Preparation and application of multi-layer core-shell structure magnetic nano-photocatalyst

A multi-layer core-shell structure, photocatalyst technology, applied in the field of nanocomposite materials and photocatalysis, can solve the problems of low photocatalytic efficiency, and achieve the effects of high recovery rate and regeneration rate, controllable particle size, and good monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

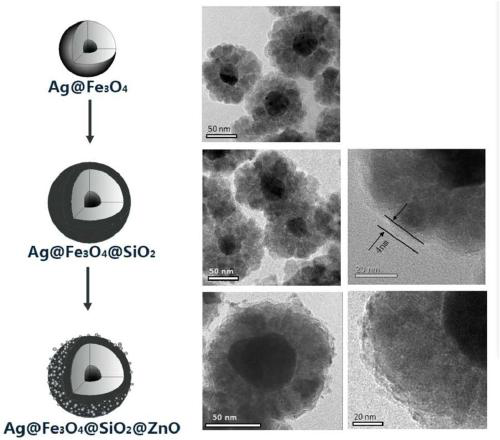

[0027] ① Synthesis of Ag@Fe3O4 nanoparticles: Add Fe(NO3) 9H2O (4mmol), NaAc (35mmol) and AgNO3 (0.59mmol) to ethylene glycol (40mL), stir magnetically until completely dissolved and transfer to polytetrafluoroethylene In an inner stainless steel autoclave, react at 200°C for 8 hours. After the reaction, it was washed several times with ethanol, collected by magnetic force, and dried overnight in a vacuum oven at 60°C.

[0028] ②Synthesis of Ag@Fe3O4@SiO2 nanoparticles: Mix 38mL ethanol and 6mL deionized water, add 0.1gAg@Fe3O4 nanoparticles, stir mechanically, add 2mL ammonia water, then drop 0.38mL TEOS into the mixture, and stir for 3 hours , The resulting product was washed several times with ethanol, collected by magnetic force, and dried overnight in a vacuum oven at 50°C.

[0029] ③Synthesis of Ag@Fe3O4@SiO2@ZnO nanoparticles: ZnNO3×6H2O (0.3 g) was dissolved in DMF (50 mL), NaOH (0.04 g) was dissolved in deionized water (2 mL), Ag@Fe3O4@SiO2 (0.5 g) Sonication Dissol...

Embodiment 2

[0032] Same as Example 1, the difference from Example 1 is that the autoclave reaction temperature in step 1) is 160°C.

Embodiment 3

[0034] Same as Example 1, the difference from Example 1 is that the autoclave reaction temperature in step 1) is 240°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com