Ultrasonic-assisted laser-deposition additive manufacturing method and device

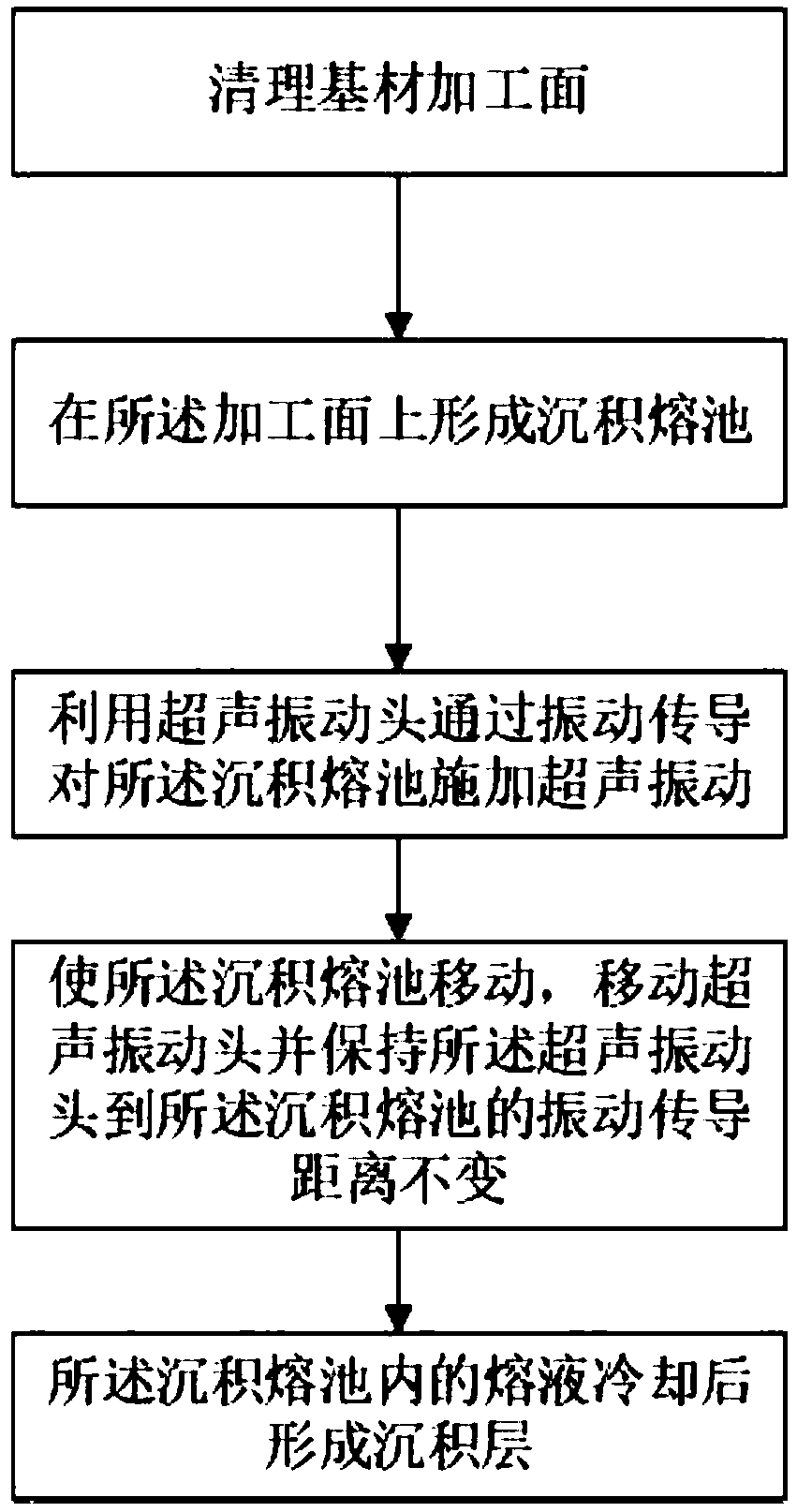

An auxiliary laser and additive manufacturing technology, which is applied in the field of additive manufacturing, can solve the problems of unstable deposit layer quality, uneven distribution of deposit layer structure, poor overall mechanical properties, etc., and improve the uniformity and uniformity of the deposit layer. , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

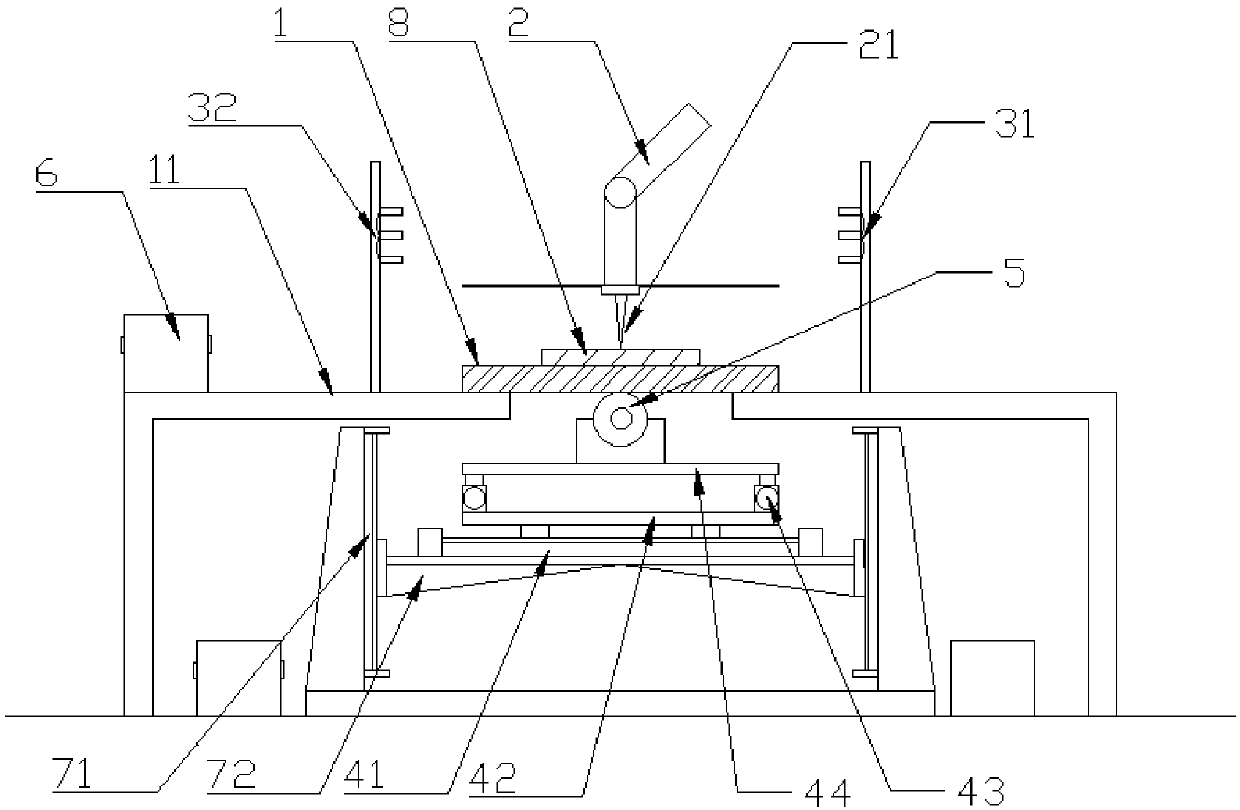

[0087] As a specific embodiment of the ultrasonic-assisted laser deposition additive manufacturing method provided by the present invention, moving the ultrasonic vibration head 5 and keeping the vibration transmission distance from the ultrasonic vibration head 5 to the deposition molten pool unchanged includes:

[0088] Move the ultrasonic vibrating head 5 and keep the relative position of the ultrasonic vibrating head 5 and the deposition molten pool fixed.

[0089] Specifically, when the deposition molten pool moves in a direction parallel to the plate surface of the substrate 1, the ultrasonic vibration head 5 moves along the lower surface of the substrate 1 in the same manner as the deposition molten pool, so that the ultrasonic vibration head 5 and the deposition molten pool The relative position is kept fixed, and the vibration transmission distance between the ultrasonic vibrating head 5 and the deposition molten pool is kept constant.

[0090] As a specific implement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com