Method and device for monitoring inner wall temperature during surfacing of non-melting polar electric arc cylinder

A non-melting electrode and monitoring device technology, applied in the direction of arc welding equipment, welding equipment, welding accessories, etc., can solve the problems that the closed-loop control of the welding process cannot be realized, the accumulation of heat input cannot be controlled, and the stability of the temperature measurement method is poor. Dilution rate, improvement of molding quality and dimensional accuracy, and effects of uniform tissue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

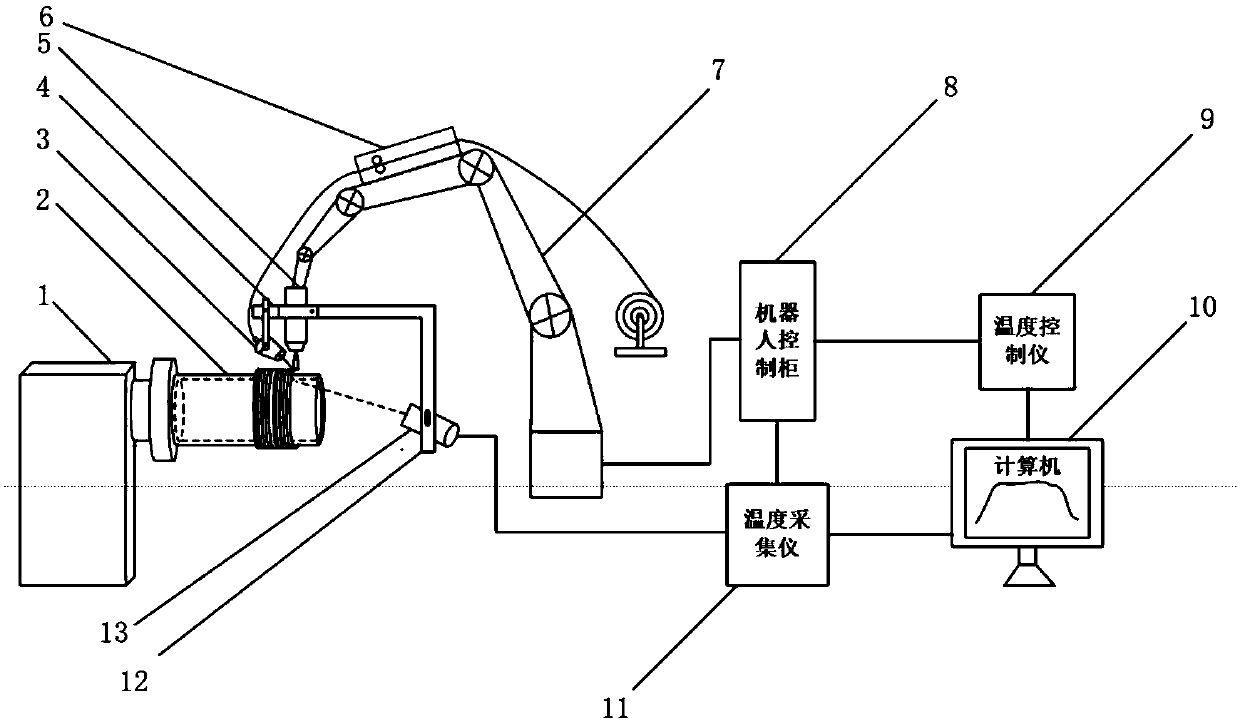

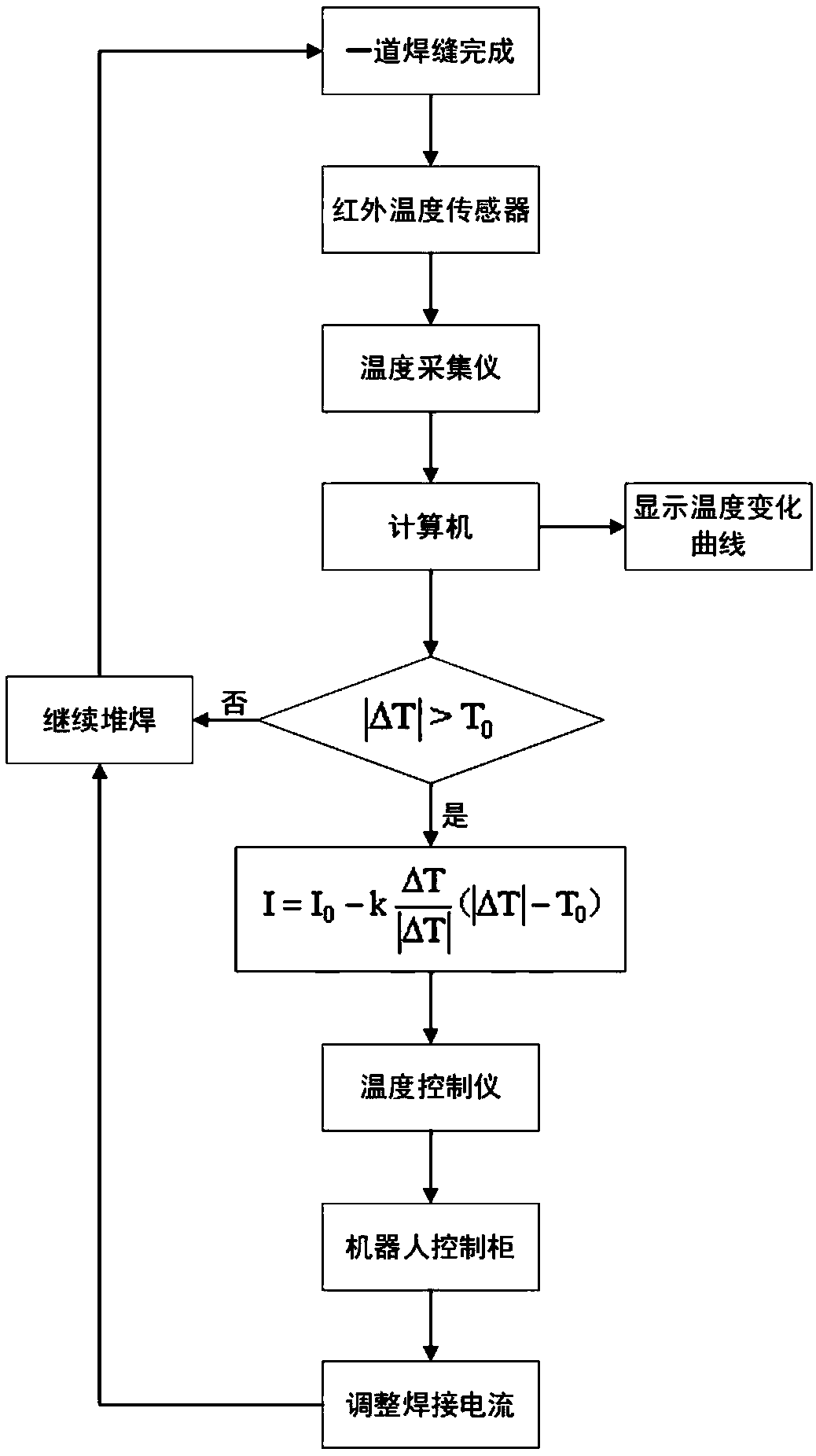

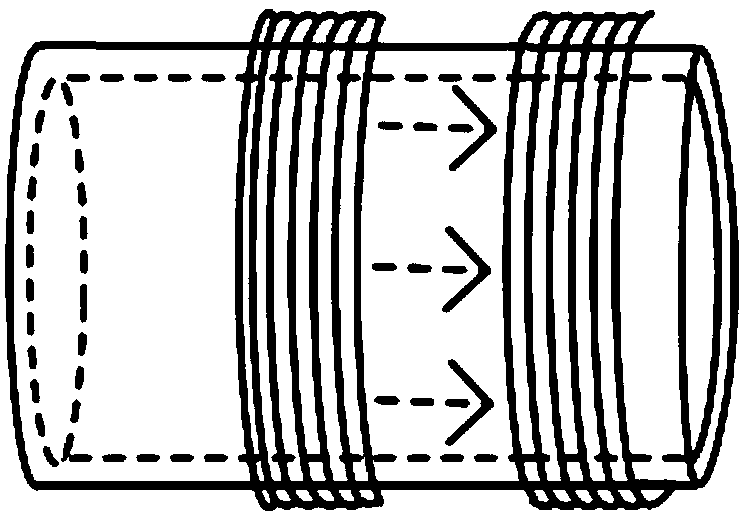

[0033] The invention provides an inner wall temperature detection and control device for surfacing welding of non-melting electrode arcs on steel cylinders, comprising: a positioner, a steel cylinder on the positioner, a plasma torch, an infrared temperature sensor and its A fixing fixture, a temperature acquisition instrument, a temperature controller, a computer, and a robot control cabinet connected with the temperature controller. The infrared temperature sensor is used to detect the temperature information of the inner wall at the relative position of the welding torch; the temperature acquisition instrument is used for filtering and scale conversion of the temperature sensing signal; the computer converts the temperature information converted by the temperature acquisition instrument in the form of a dynamic curve Display and compare the detected temperature with the preset temperature, calculate the adjusted welding current value, and output the control signal; the tempe...

Embodiment 2

[0041] The invention provides an inner wall temperature detection and control device for surfacing welding of non-melting electrode arcs on steel cylinders, comprising: a positioner, a steel cylinder on the positioner, a plasma torch, an infrared temperature sensor and its A fixing fixture, a temperature acquisition instrument, a temperature controller, a computer, and a robot control cabinet connected with the temperature controller. The infrared temperature sensor is used to detect the temperature information of the inner wall at the relative position of the welding torch; the temperature acquisition instrument is used for filtering and scale conversion of the temperature sensing signal; the computer converts the temperature information converted by the temperature acquisition instrument in the form of a dynamic curve Display and compare the detected temperature with the preset temperature, calculate the adjusted welding current value, and output the control signal; the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com