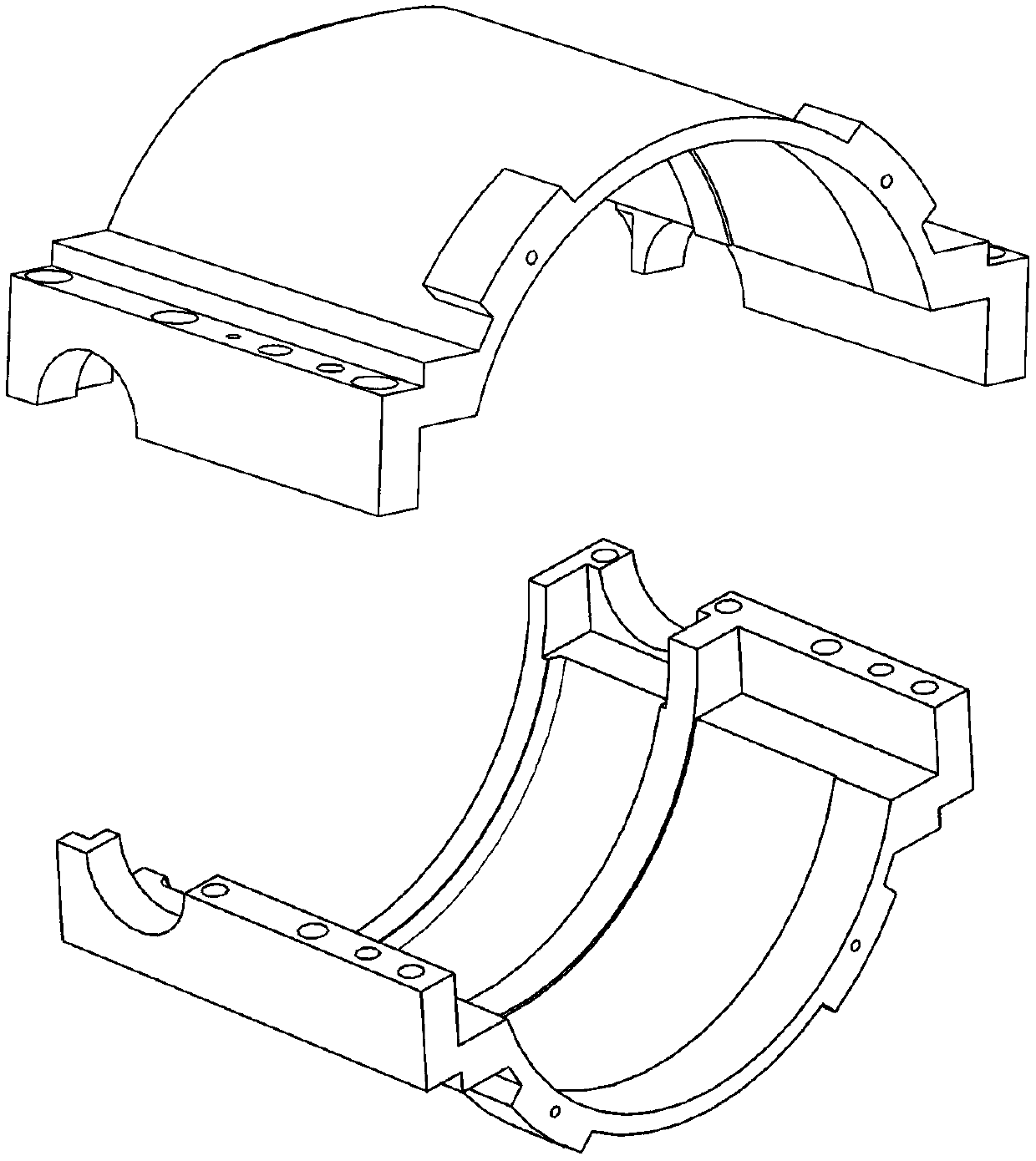

Machining method of high-accuracy thin-wall titanium alloy part with open-type structure

A processing method and an open technology, applied in the processing field of high-precision structure open thin-walled titanium alloy parts, can solve the problems of large deformation, size change, long cycle, etc., to improve mechanical properties, improve stress distribution, reduce The effect of small material deformations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

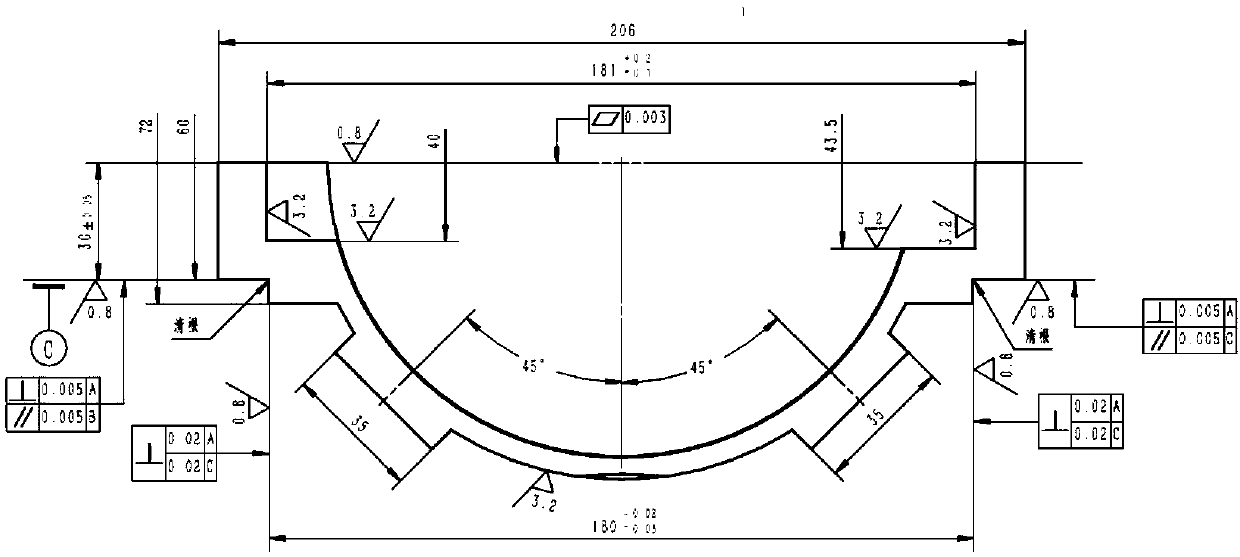

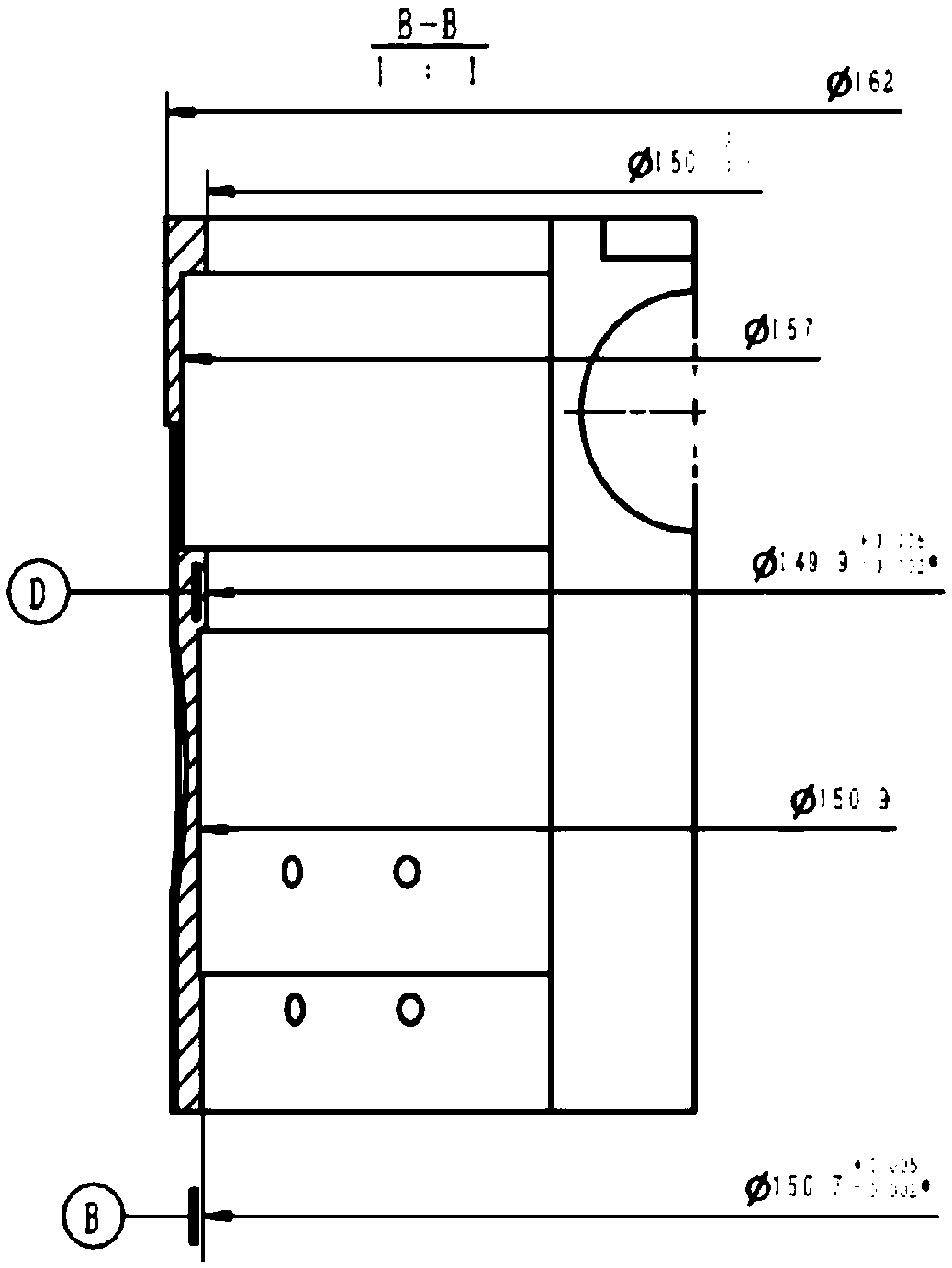

[0018] Based on the characteristics that the cryogenic treatment can eliminate the residual stress of the material, improve its mechanical properties, and the deformation of the material before and after treatment is small, it adopts casting forming-rough machining shape-cryogenic treatment-semi-finishing shape-via hole and thread processing-cryogenic treatment- The finishing process route realizes the processing of high-precision open-type thin-walled titanium alloy parts.

[0019] The technical solution of the present invention is to cast the parts according to the parts casting drawings; use the vertical machining center to preliminarily remove most of the margins of the shape, drill and bore the pin holes, and remove most of the margins of the inner holes on the lathe after the pin holes are positioned; Put the workpiece into the cryogenic treatment equipment, fill it with liquid nitrogen, reach -80°C and -180°C in stages, soak it for two hours, then slowly raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com