Isostatic pressing method for refractory polybenzimidazole

A technology of isostatic pressing and polybenzimidazole, which is applied in the field of refractory polymer molding, can solve problems such as limitations, the inability to apply PBI high-performance matrix resin, and the inability to break through the overall molding problem, and achieves optimization of mechanical properties, The effect of good machinability and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

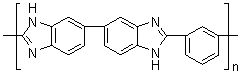

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of isostatic pressing molding method of refractory polybenzimidazole comprises the following steps:

[0035] ⑴Cold isostatic pressing into blank:

[0036] At room temperature, in an air atmosphere, put 130 g of polybenzimidazole molding powder into a flexible rubber sleeve, apply a pressure of 20 MPa in a cold isostatic press, and keep it for 5 hours; after the pressing is completed, remove the rubber sleeve to obtain Cold isostatic pressing blank.

[0037] ⑵The welding seal of the sheath:

[0038] The sheath is made of pure aluminum, and its shape is a hollow thin-walled cylinder with one end closed and the other open. Put the cold isostatic pressing blank into the sheath, then weld the sheath cover with the exhaust pipe on the opening end of the sheath, and use a vacuum pump to evacuate to 1×10 -2 Pa, and then use hydraulic sealing pliers to seal the exhaust pipe to obtain the workpiece to be pressed in which the aluminum sheath encapsulates the...

Embodiment 2

[0042] Embodiment 2 A kind of isostatic pressing forming method of refractory polybenzimidazole comprises the following steps:

[0043] ⑴Cold isostatic pressing into blank:

[0044] At room temperature, in an air atmosphere, put 65 g of polybenzimidazole molding powder into a flexible rubber sleeve, apply a pressure of 50 MPa in a cold isostatic press, and keep it for 4 hours; after the pressing is completed, remove the rubber sleeve to obtain Cold isostatic pressing blank.

[0045] ⑵The welding seal of the sheath:

[0046] The sheath is made of pure aluminum, and its shape is a hollow thin-walled cylinder with one end closed and the other open. Put the cold isostatic pressing blank into the sheath, then weld the sheath cover with the exhaust pipe on the opening end of the sheath, and use a vacuum pump to evacuate to 7×10 -3 Pa, and then use hydraulic sealing pliers to seal the exhaust pipe to obtain the workpiece to be pressed in which the aluminum sheath encapsulates the ...

Embodiment 3

[0050] Embodiment 3 A kind of isostatic pressing forming method of refractory polybenzimidazole comprises the following steps:

[0051] ⑴Cold isostatic pressing into blank:

[0052] At room temperature, in an air atmosphere, put 195 g of polybenzimidazole molding powder into a flexible rubber sleeve, apply a pressure of 80 MPa in a cold isostatic press, and keep it for 3 hours; after the pressing is completed, remove the rubber sleeve to obtain Cold isostatic pressing blank.

[0053] ⑵The welding seal of the sheath:

[0054] The sheath is made of pure aluminum, and its shape is a hollow thin-walled cylinder with one end closed and the other open. Put the cold isostatic pressing blank into the sheath, then weld the sheath cover with the exhaust pipe on the opening end of the sheath, and use a vacuum pump to evacuate to 5.2×10 -3 Pa, and then use hydraulic sealing pliers to seal the exhaust pipe to obtain the workpiece to be pressed in which the aluminum sheath encapsulates t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com