Metal particle-bearing macromolecular curing agent and application thereof

A technology of polymer curing agent and metal particles, applied in the field of water treatment, can solve the problems of low equipment stability, low catalytic efficiency, short service life, etc., and achieve easy batch industrial production, simple structure, and convenient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

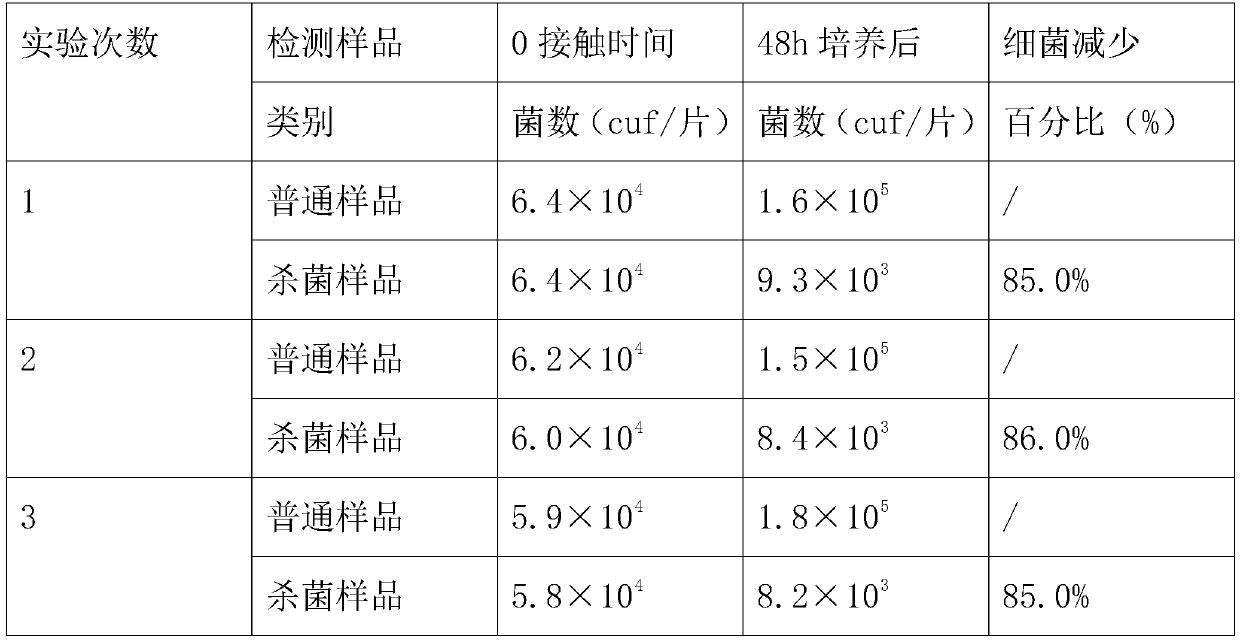

Examples

Embodiment 1

[0031] Weigh 140g epoxy resin, 0.5g copper powder (particle size 5nm), 0.1g cobalt powder (particle size 100nm), 1g titanium dioxide (particle size 100μm). First pour 70 grams of epoxy resin into a 10mm-12mm thick sheet. After 8 hours, when the epoxy resin is in a semi-cured state, sprinkle the above powder evenly on the epoxy resin sheet, and then use another 70 grams of ring The epoxy resin is poured on it, wait for the epoxy resin to fully cure, and the preparation is completed.

[0032] A magnetic field environment is placed around the above-mentioned epoxy resin carrying metal particles, and a catalytic light source with a wavelength of 300nm-600nm and a frequency of 8Hz-15Hz is placed above the water container. The height of the water container is 400mm. The epoxy resin is lower than 10mm from the water surface, and without contact with water, it will break the hydrogen bonds of water molecules and form small molecular clusters of water.

[0033] a. NMR testing data:

...

Embodiment 2

[0042] Weigh 140g epoxy resin, 0.05g cobalt powder (10nm particle size), and 2g titanium dioxide (100nm particle size). First pour 70 grams of phenolic resin into a 10mm-12mm thick sheet. After 8 hours, when the phenolic resin is in a semi-cured state, sprinkle the above powder evenly on the phenolic resin sheet, and pour another 70 grams of phenolic resin on it, and wait. The phenolic resin is all cured, and the preparation is complete.

[0043] A magnetic field environment is placed around the above-mentioned phenolic resin carrying metal particles, and a catalytic light source with a wavelength of 300nm-600nm and a frequency of 8Hz-15Hz is placed above the water container, and the height of the water container is 400mm. The resin is lower than 10mm from the water surface, and without contact with water, it breaks the hydrogen bonds of water molecules and generates small molecular clusters of water.

[0044] After testing, the nuclear magnetic resonance frequency is 9.2HZ, ...

Embodiment 3

[0046]Weigh 140g epoxy resin and 1g cobalt powder (100nm particle size). First pour 70 grams of epoxy resin into a 10mm-12mm thick sheet. After 8 hours, when the epoxy resin is in a semi-cured state, sprinkle the above powder evenly on the epoxy resin sheet, and then use another 70 grams of ring The epoxy resin is poured on it, wait for the epoxy resin to fully cure, and the preparation is completed.

[0047] A magnetic field environment is placed around the above-mentioned epoxy resin carrying metal particles, and a catalytic light source with a wavelength of 300nm-600nm and a frequency of 8Hz-15Hz is placed above the water container. The height of the water container is 400mm. The epoxy resin is lower than 10mm from the water surface, and without contact with water, it will break the hydrogen bonds of water molecules and form small molecular clusters of water.

[0048] After testing, the nuclear magnetic resonance frequency is 15Hz, and the viscosity is 0.009×10 -3 , after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com