Method for effectively removing iodinated X-ray contrast agent in water

An X-ray and water removal technology, which is applied in the field of effective removal of iodine X-ray contrast agents in water, can solve the problems of difficult ICM removal and achieve the effects of outstanding safety, reduced production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

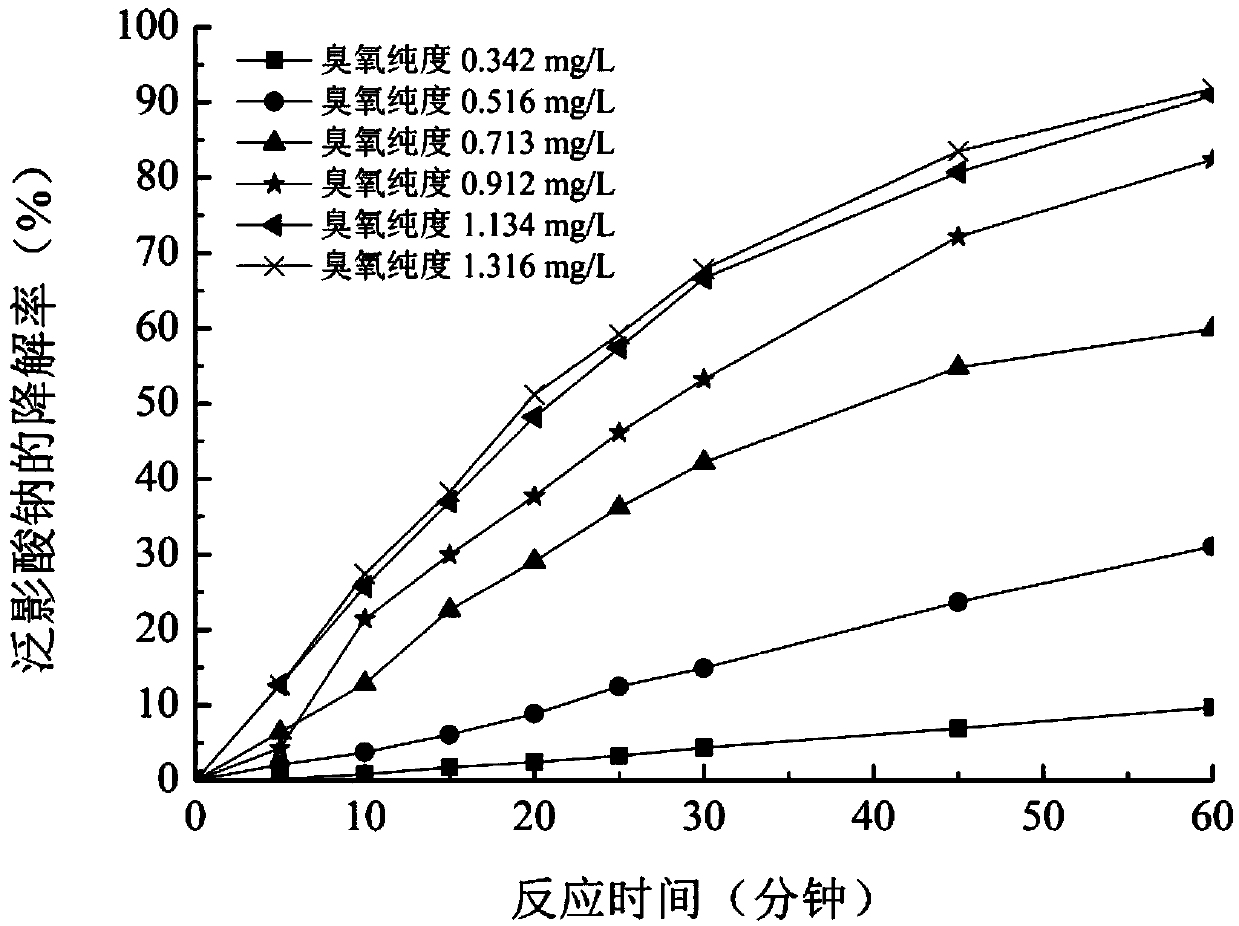

[0026] Taking sodium diatrizoate as an example, adjust the raw water containing 10 μM sodium diatrizoate to pH = 7, control the temperature at 25°C, pass ozone gas into the reaction solution and mix it evenly, and the reaction time is 60 minutes. Calculated according to the purity of ozone, the purity of ozone gas passed into the solution is 0.342mg / L, 0.516mg / L, 0.713mg / L, 0.912mg / L, 1.134mg / L and 1.316mg / L respectively. , the degradation rate of sodium diatrizoate varies with the reaction time as figure 1 shown.

[0027] from figure 1 It can be seen that there are significant differences in the degradation rate of sodium diatrizoate at the same reaction time under the addition of ozone gas of different purity. When the ozone gas purity reached 0.516mg / L, the degradation rate was 31.1%; after that, increasing the ozone gas purity significantly increased the degradation rate of sodium diatrizoate, when the ozone gas purity reached 1.134mg / L , the degradation rate of sodium ...

Embodiment 2

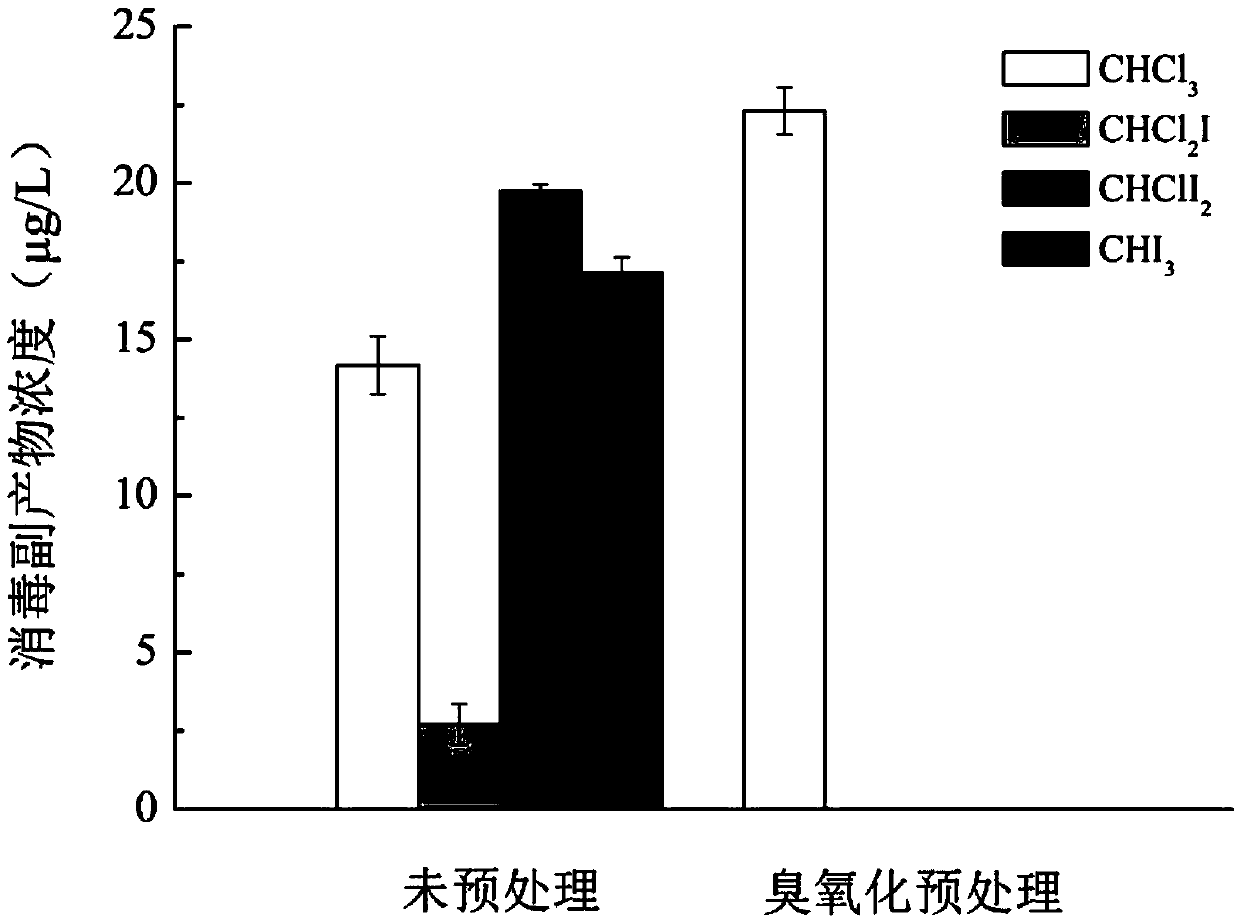

[0029] Taking sodium diatrizoate as an example, adjust the raw water containing 10 μM sodium diatrizoate to pH = 7, control the temperature at 25°C, pass ozone gas into the reaction solution and mix it evenly, calculate according to the purity of ozone, The purity of the ozone gas introduced into the solution was 0.713 mg / L. After 60 minutes of reaction, 7 mg / L chlorine was added to the reaction solution. After the chlorination reaction at 25°C for 3 days, the amount of I-THMs produced is as follows figure 2 shown.

[0030] When no ozone pretreatment was performed, sodium diatrizoate produced three I-THMs (triiodomethane, dichloromonoiodomethane, monochlorodiiodomethane) and chloroform after chlorination; After treatment, only chloroform was detected as a disinfection by-product from the chlorination of the solution. Compared with the solution after direct chlorination, although the concentration of chloroform produced by the ozone pretreated solution after chlorination is ...

Embodiment 3

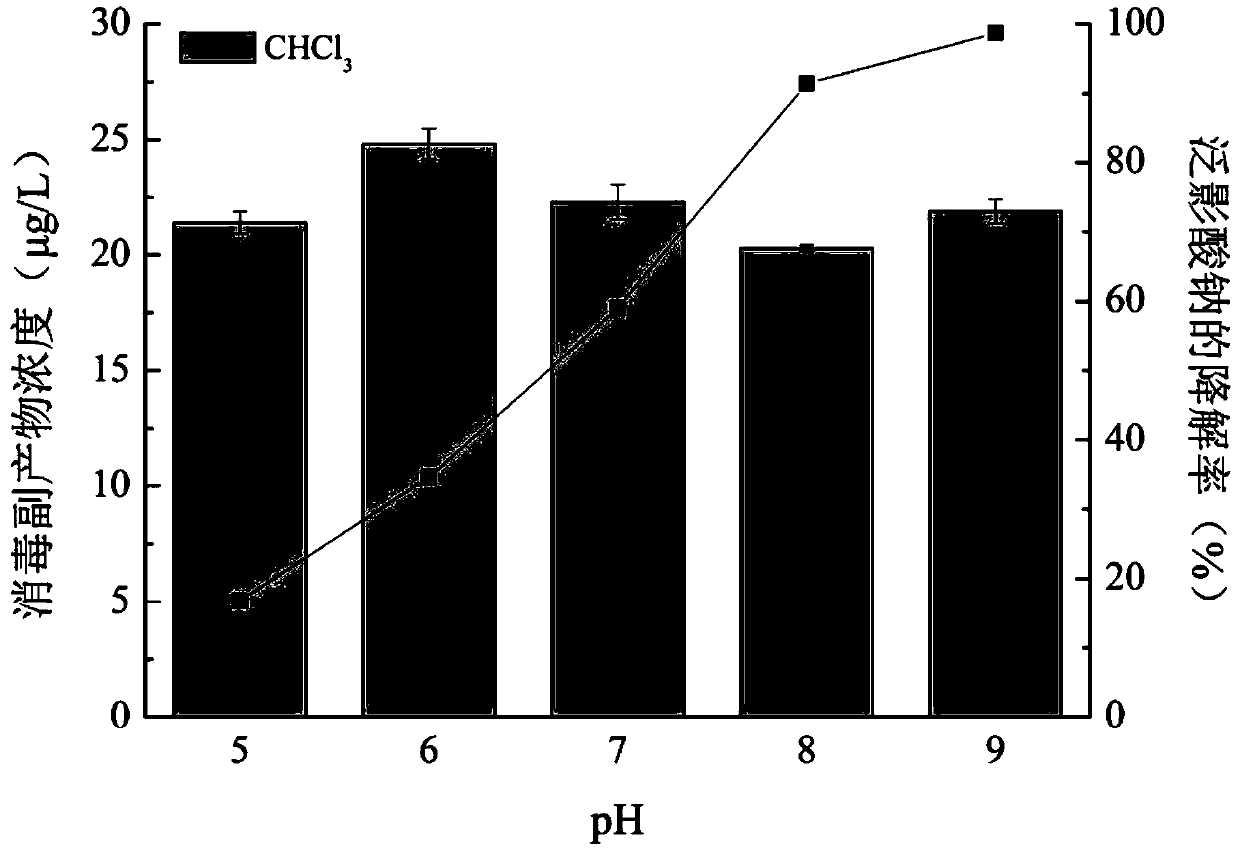

[0032] Taking sodium diatrizoate as an example, control the temperature of the raw water containing 10 μM sodium diatrizoate at 25°C, adjust the pH of the reaction solution, and pass through the reaction solution when the pH is 5, 6, 7, 8, and 9 respectively Enter ozone gas and make it mix, calculate by the purity of ozone, lead to the ozone gas purity that feeds in the solution is 0.713mg / L, after reacting 60min, sodium diatrizoate degradation rate changes with reaction time as follows image 3 shown. Then 7 mg / L chlorine was added to the reaction solution. After the chlorination reaction at 25°C for 3 days, the amount of I-THMs produced is as follows image 3 shown.

[0033] The degradation rate of sodium diatrizoate is affected by the change of pH. With the decrease of pH value, the degradation rate of sodium diatrizoate decreases significantly. When pH=5, the degradation rate of sodium diatrizoate was only 16.8%, but when pH=9, the degradation rate was as high as 98.7%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com