Aeration tank, sewage treatment system and sewage treatment method

A sewage treatment system and aeration tank technology, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low sewage treatment efficiency and long sewage residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

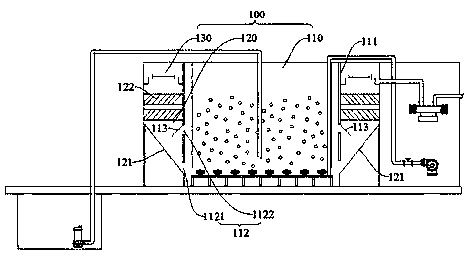

[0078] figure 1 It is a schematic structural diagram of the aeration tank provided in Example 1 of the present invention.

[0079] refer to figure 1 As shown, Embodiment 1 of the present invention provides an aeration tank 100, the aeration tank 100 includes an aeration area 110 and a sedimentation area 120 connected to each other, wherein, the sedimentation area 120 is provided with at least one set of slopes along the vertical direction Type settling assembly 122, a plurality of inclined flow channels are formed in the inclined settling assembly 122, when the water flows from the bottom of the inclined settling assembly 122 to the top of the inclined settling assembly 122, the inner wall of the inclined flow channel blocks the sediment in the water flow .

[0080] The aeration tank 100 provided in Embodiment 1 of the present invention includes an aeration area 110 and a sedimentation area 120 connected to each other, wherein at least one set of inclined sedimentation compo...

Embodiment 2

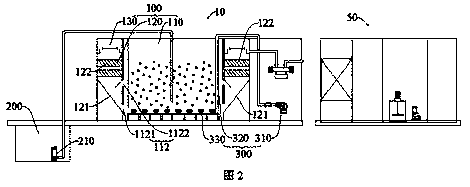

[0096] figure 2 It is a schematic structural diagram of the sewage treatment system provided by Embodiment 2 of the present invention.

[0097] Based on the foregoing embodiment one, refer to figure 2 As shown, the second embodiment of the present invention provides a sewage treatment system, the sewage treatment system includes a primary treatment equipment 10 and a secondary treatment equipment 50 connected to each other, the primary treatment equipment 10 includes any optional implementation of the first embodiment of the present invention The aeration tank 100 provided by the method, the regulating tank 200 and the air delivery device 300 communicated with the aeration tank 100;

[0098] The adjustment tank 200 is used to adjust the physical and chemical properties of the sewage. The adjustment tank 200 has a lifting pump 210, and the lifting pump 210 is used to send the sewage into the aeration tank 100;

[0099] The air supply device 300 includes an air booster assembl...

Embodiment 3

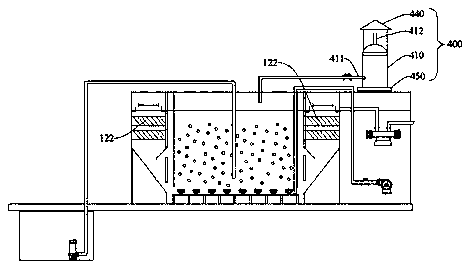

[0103] image 3 Schematic diagram of the structure of the primary treatment equipment in the sewage treatment system provided by Embodiment 3 of the present invention; Figure 4 Schematic diagram of the structure of the waste gas treatment device in the sewage treatment system provided by Embodiment 3 of the present invention; Figure 5 It is a schematic structural diagram of the biological filler layer in the sewage treatment system provided by Embodiment 3 of the present invention.

[0104] Based on the foregoing embodiment one or embodiment two, refer to Figure 3 to Figure 5 As shown, the third embodiment of the present invention provides a sewage treatment system, the primary treatment equipment 10 also includes a waste gas treatment device 400; the waste gas treatment device 400 includes a reactor 410 and a biological filler layer 420 arranged in the reactor 410, the reactor 410 has an air inlet 411 and an air outlet 412, the air inlet 411 is located at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com