Bread frozen dough with excellent yeast frost resistance and preparation method thereof

A technology for freezing dough and bread, which is applied in the direction of dough preparation, dough processing, pre-baked dough processing, etc. It can solve the problems of affecting the appearance and taste of bread, small bread, and the decrease of fermentation capacity of yeast cells with holding power, so as to improve the quality of yeast Survival rate and frost resistance, air holding capacity and water holding rate are improved, and the effect of technological progress is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

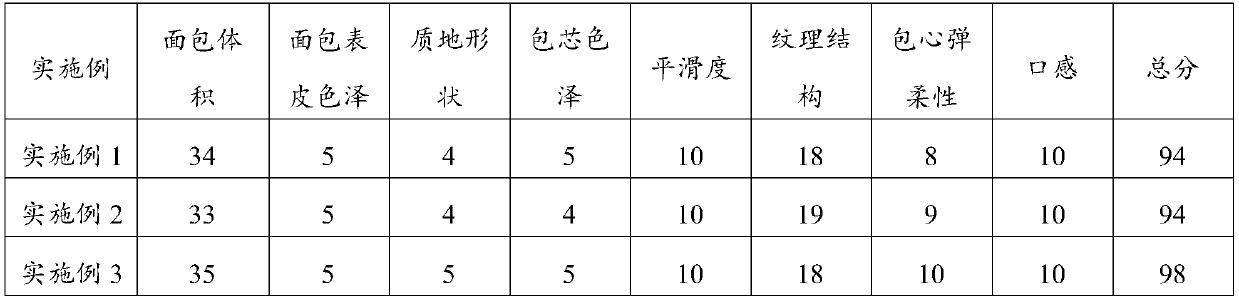

Examples

Embodiment 1

[0058] A kind of bread frozen dough with good antifreeze property of yeast, the processing raw material weight part composition of described frozen bread dough is as follows:

[0059] 15 parts of spirulina powder;

[0060] 40 parts of high-gluten wheat flour;

[0061] 0.5 part refined salt;

[0062] 5 parts white sugar;

[0063] 6 parts whole milk powder;

[0064] 1.2 parts of active dry yeast;

[0065] 2 parts of compound frozen dough improver, described compound frozen dough improver is used in combination with mass ratio 8: 1 by base material and functional material, and the weight percent of base material is formed as follows: 5% modified phospholipid, 10% Sucrose Fat, 5% Calcium Stearyl Lactate, 15% Diacetyl Tartrate Monoglyceride, 5% Monoglyceride, 10% Gluconolactone, 10% Compound Enzyme, The Balance is Starch, the sum is 100% ;

[0066] The weight percent composition of the functional material is as follows: 20% trehalose, 10% water-soluble and water-insoluble dex...

Embodiment 2

[0082] A kind of bread frozen dough with good antifreeze property of yeast, the processing raw material weight part composition of described frozen bread dough is as follows:

[0083] 25 parts of spirulina powder;

[0084] 60 parts of high-gluten wheat flour;

[0085] 2.0 parts refined salt;

[0086] 8 parts white sugar;

[0087] 10 parts whole milk powder;

[0088] 1.8 parts of active dry yeast;

[0089] 4 parts of compound frozen dough improver, described compound frozen dough improver is used in combination with mass ratio 10: 1 by base material and functional material, and the weight percentage of base material is made up as follows: 12% modified phospholipid, 20% Sucrose lipid, 5% sodium stearoyl lactylate, 15% diacetyl tartrate monoglyceride, 5% monoglyceride, 10% gluconolactone, 10% complex enzyme, the balance is starch, the sum is 100% ;

[0090] The weight percent composition of the functional material is as follows: 30% trehalose, 20% water-soluble and water-in...

Embodiment 3

[0106] A kind of bread frozen dough with good antifreeze property of yeast, the processing raw material weight part composition of described frozen bread dough is as follows:

[0107] 20 parts of spirulina powder;

[0108] 50 parts of high-gluten wheat flour;

[0109] 1.2 parts refined salt;

[0110] 6 parts white sugar;

[0111] 8 servings of whole milk powder;

[0112] 1.5 parts active dry yeast;

[0113] 3 parts of compound frozen dough improver, said compound frozen dough improver is used in conjunction with base material and functional material with mass ratio 9: 1 composition, and the weight percentage of base material is composed as follows: 8% modified phospholipid, 15% Sucrose Lipid, 8% Calcium Stearyl Lactate or Sodium Stearoyl Lactylate, 18% Diacetyl Tartrate Monoglyceride, 8% Monoglyceride, 15% Gluconolactone, 12% Complex Enzyme, 16% starch;

[0114] The weight percent composition of the functional material is as follows: 25% trehalose, 15% water-soluble and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com