Composite quality improver for frozen dough and preparation method of composite quality improver

A quality improver and a technology for freezing dough, which is applied in dough processing, pre-baking dough processing, baking, etc., can solve problems such as affecting the appearance and taste of bread, small size of bread, and decreased fermentation capacity of air-holding yeast cells. Improved yeast survival rate and frost resistance, improved air and water holding capacity, and significant technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

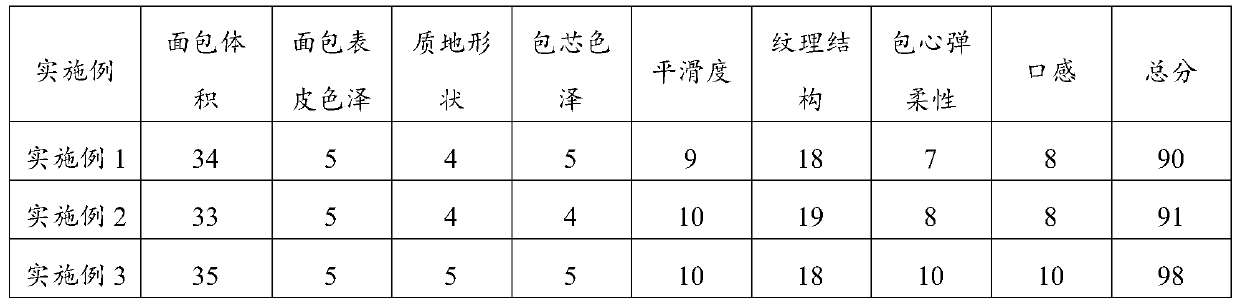

Examples

Embodiment 1

[0043] A composite frozen dough quality improver, the composite frozen dough quality improver is used in a combination of a base material and a functional material in a mass ratio of 8:1, and the weight percentage of the base material is composed as follows: 5% modified phospholipid, 10% Sucrose lipid, 5% calcium stearate lactate, 15% diacetyltartaric acid monoglyceride, 5% monoglyceride, 10% gluconolactone, 10% complex enzyme, the balance is starch, the total is 100% ;

[0044] The weight percentage composition of the functional material is as follows: 20% trehalose, 10% water-soluble and water-insoluble glucan compound, and the balance is the extract of the octagonal gold plate seed, the total is 100%.

[0045] In this embodiment, the mass ratio of water-soluble and water-insoluble glucan in the functional material is 1:1, the composite enzyme includes 2% glucose oxidase and 2.5% hemicellulase, and the balance is xylan Enzyme.

[0046] In this embodiment, the extraction method of...

Embodiment 2

[0058] A composite frozen dough quality improver. The composite frozen dough quality improver is used in combination with a base material and a functional material at a mass ratio of 10:1, and the weight percentage of the base material is composed as follows: 12% modified phospholipid, 20% Sucrose lipid, 5% sodium stearoyl lactylate, 15% diacetyl tartaric acid monoglyceride, 5% monoglyceride, 10% gluconolactone, 10% complex enzyme, the balance is starch, the total is 100% ;

[0059] The composition by weight percentage of the functional material is as follows: 30% trehalose, 20% water-soluble and water-insoluble glucan compound, the balance is the extract of the octagonal gold plate seed, the total is 100%.

[0060] In this embodiment, the mass ratio of water-soluble and water-insoluble glucan in the functional material is 5:3, the composite enzyme includes 3% glucose oxidase and 2.5% hemicellulase, and the composite enzyme also includes 3.5% xylanase, 1.0% maltose amylase.

[0061...

Embodiment 3

[0073] A composite frozen dough quality improver, which is composed of a base material and a functional material in a mass ratio of 9:1. The weight percentage of the base material is composed as follows: 8% modified phospholipid, 15% Sucrose lipid, 8% calcium stearyl lactate or sodium stearoyl lactylate, 18% diacetyl tartrate monoglyceride, 8% monoglyceride, 15% gluconolactone, 12% complex enzyme, 16% starch;

[0074] The weight percentage composition of the functional material is as follows: 25% trehalose, 15% water-soluble and water-insoluble glucan complex, 60% octagonal golden seed extract.

[0075] The mass ratio of water-soluble and water-insoluble glucan in the functional material described in Example 3 is 4:3, and the composite enzyme includes 2.5% glucose oxidase, 2.0% hemicellulase, 3.0% maltose amylase, 2.5% % Alpha-amylase and 2% lipase.

[0076] In Example 3, the extraction method of the star anise gold seed extract is as follows:

[0077] Step S1: Crushed raw material:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com