Aquatic feed pre-digestion method and product and application thereof

A technology of aquatic feed and pre-digestion, which is applied in application, animal feed, animal feed, etc., can solve problems such as difficulty in meeting actual needs, and achieve the effects of solving safety, promoting digestion and absorption rate, and stabilizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

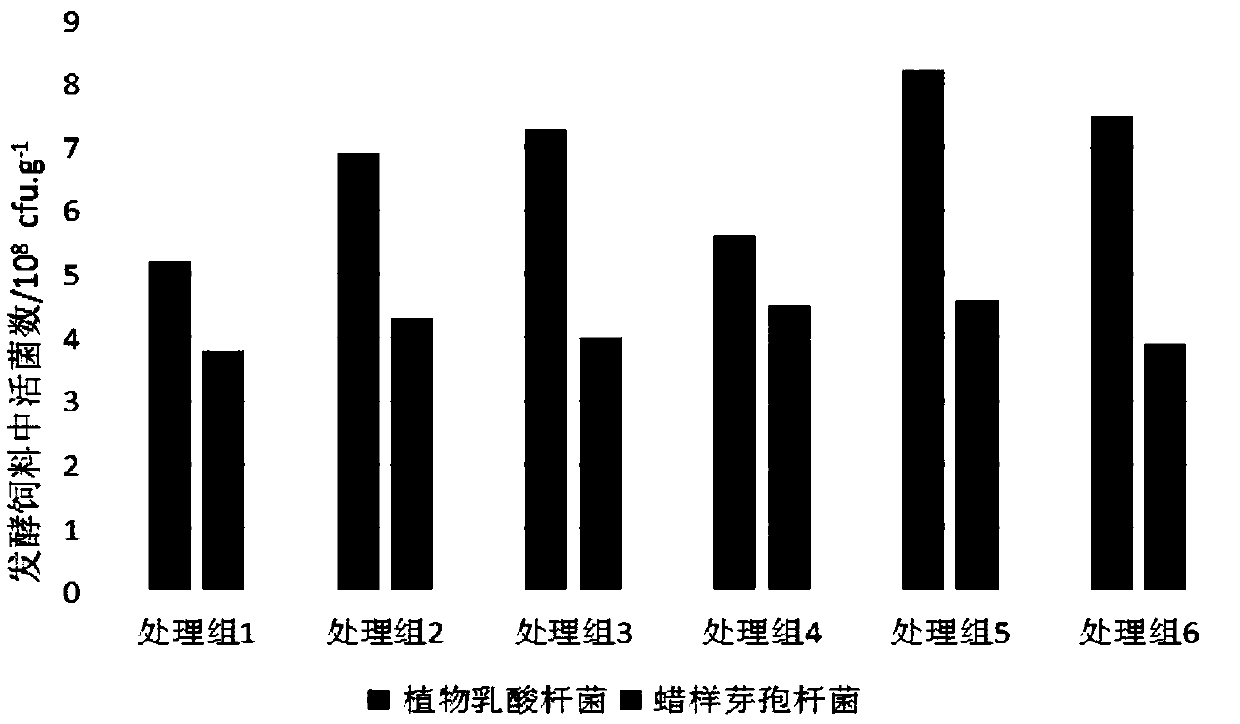

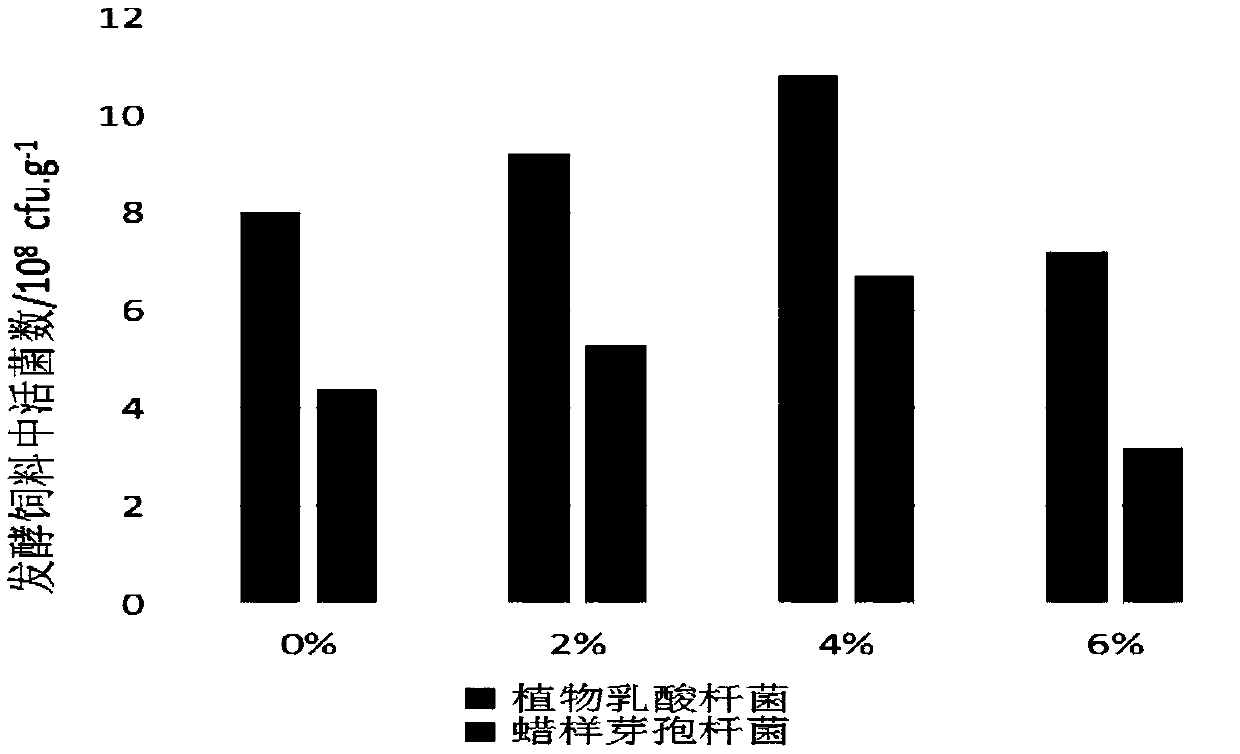

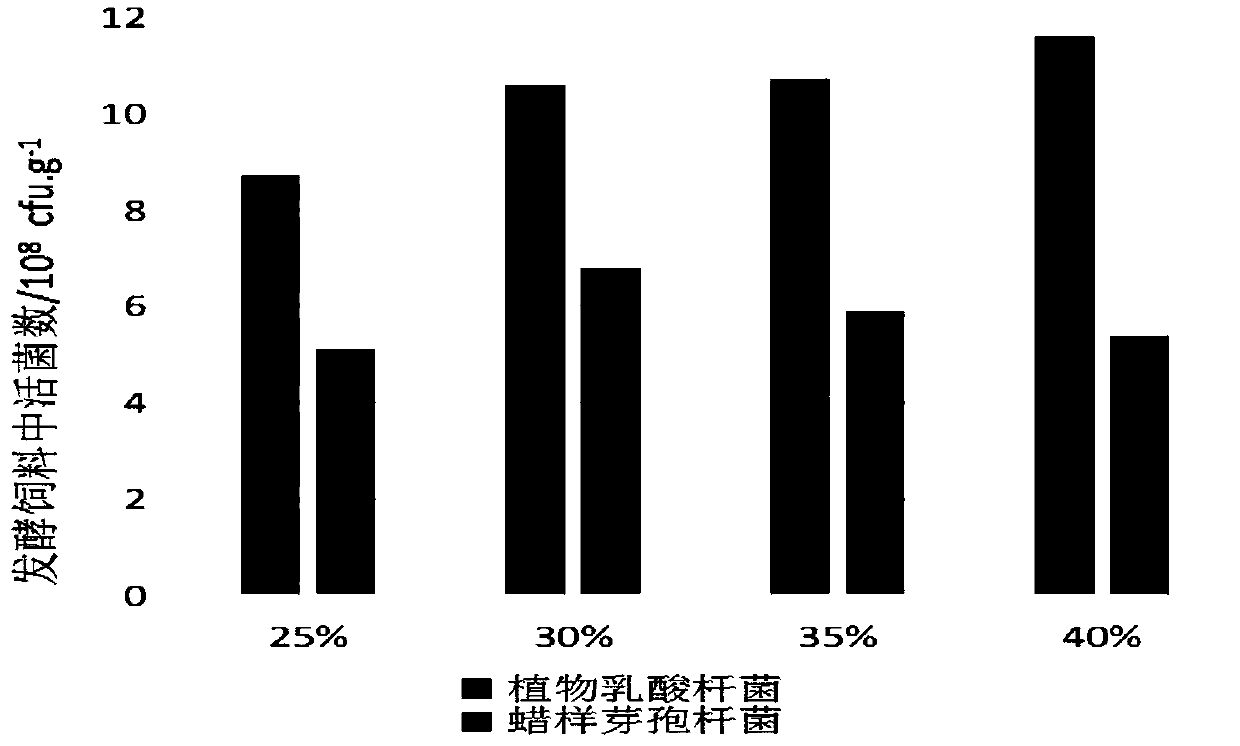

[0034] Add 4% Lactobacillus plantarum, 0.3% Bacillus cereus and 4% molasses in the aquatic feed, add water to adjust the water content of the feed to 30%, adjust the pH value to 6.5, stir evenly, divide into thick plastic bags, tie Tighten the mouth of the bag and ferment for 24 hours at room temperature. The experiment was repeated three times, and the results are shown in Table 2.

[0035] Table 2 Feed predigestion treatment results

[0036]

[0037] As can be seen from the data in Table 2: the results of the pre-digestion treatment of the 3 batches of 500kg feed are similar, and the average values of plant Lactobacillus, Bacillus cereus, water content and pH value in the fermented feed are respectively: 10.3×10 8 cfu / g, 6.1×10 8 cfu / g, 31% and 5.1, golden color, light fragrance. It shows that the process of feed predigestion treatment provided by the present invention is stable, and can be used for large-scale feed predigestion treatment in vitro.

Embodiment 2

[0039] Effects of Predigested Feed on Growth and Disease Resistance of Tilapia

[0040] This example was carried out in the outdoor cement pool (1.5m×3.0m×1.2m) of Guangxi Fisheries Research Institute Haike Haile Company from July 15 to September 15, 2018. The average weight of initial stocking with uniform specifications was 6.18 200 test fishes in g were randomly divided into 2 groups after being domesticated for 7 days, and each group had 2 replicates, with 50 fish in each replicate. The control group was fed with basic feed; the test group was fed directly after the feed was predigested according to the process of Example 2. After feeding for 60 days, the weight gain rate, survival rate and feed factor were calculated respectively, and streptococcus suspension was sprayed in the water body of each treatment group for challenge test, the cumulative death of tilapia within 15 days was counted, and the cumulative survival rate was calculated. The test results are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com