Compound sausage water-retaining agent and preparing and using method thereof

A water-retaining agent and sausage technology, which is applied in the direction of food ingredients as humectant, application, food ingredients containing inorganic compounds, etc., can solve the problems of sausage products losing elasticity, sausage dehydration, oil production, etc., to improve stability and enhance water retention The effect of ability and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A compound sausage water-retaining agent, comprising the following mass fraction components: 30% konjac gum (viscosity is 22000-mPa·s, glucomannan content is 75%), 16% κ-type carrageenan, 15% iota-type carrageenan , 8% KCl, 8% NaCl, 24% maltodextrin.

[0028] Prepare according to the following processing steps:

[0029] (1), successively put the raw material of above-mentioned mass parts into the conical mixer from content more to less and carry out mixed processing;

[0030] (2), after step (1) mixes 10min, discharge the compound that is 8% by mass percentage from the bottom valve of cone mixer, drop in the cone mixer again, carry out mixing processing while discharging;

[0031] (3), repeat operation above-mentioned step (2) twice;

[0032] (4), continue mixing through step (3) for 15 minutes to obtain a finished product.

[0033] Western-style sausage recipe:

[0034] 3.5 parts of chicken, 2 parts of chicken skin, 0.8 part of starch, 0.5 part of soybean protein i...

Embodiment 2

[0039] The composition and preparation method of the water-retaining agent and the preparation method of the Western-style grilled sausage are the same as in Example 1, and will not be repeated here. The difference is that the prepared compound sausage water retaining agent accounting for 1‰ of the sausage mass fraction is added to the Western-style grilled sausage.

Embodiment 3

[0041] The composition and preparation method of the water-retaining agent and the preparation method of the Western-style grilled sausage are the same as in Example 1, and will not be repeated here. The difference is that the prepared compound sausage water retaining agent accounting for 3‰ of the sausage mass fraction is added to the Western-style grilled sausage.

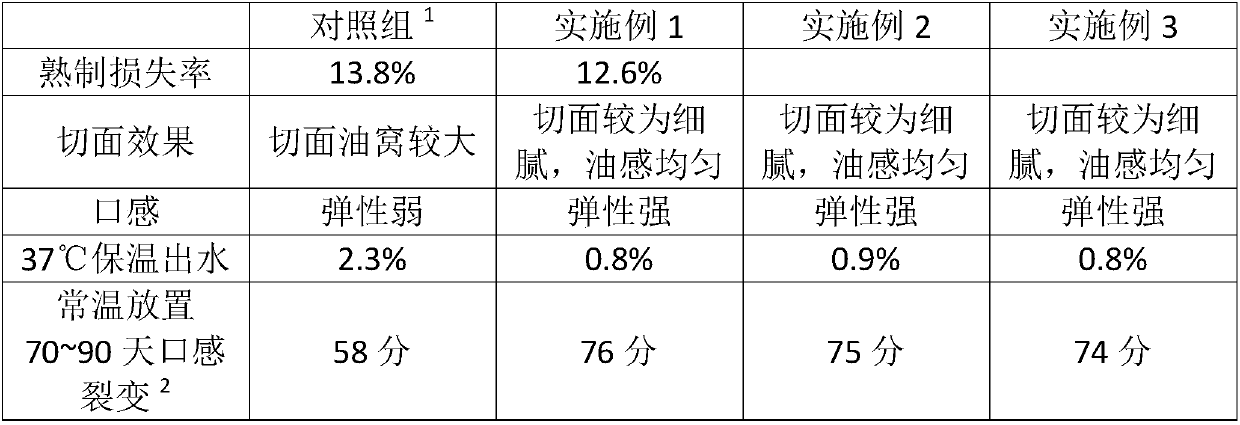

[0042] Table 1 Example 1-3 effect comparison table

[0043]

[0044] Note: 1. No water retaining agent was added to the control group;

[0045] 2. The test method of taste fission at room temperature for 70-90 days, organize 20 tasters to compare and score the two groups of products (elasticity 0-15 points; mouth moistness 0-15 points; brittleness 0-15 points; hardness 0 to 15 points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com