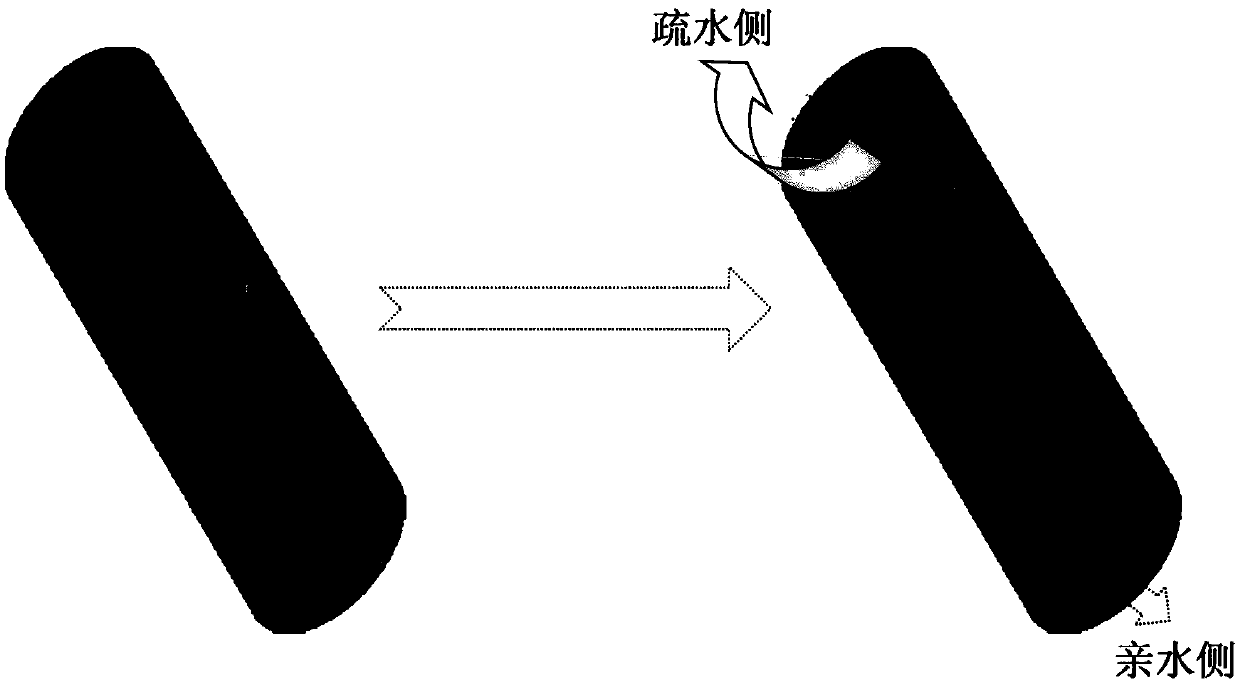

Novel Janus polymer hollow fiber membrane and preparation method and application thereof

A polymer membrane and fiber membrane technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of complex preparation procedures, uneven surface modification of membrane materials, modification of membrane materials, etc. Mild conditions, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

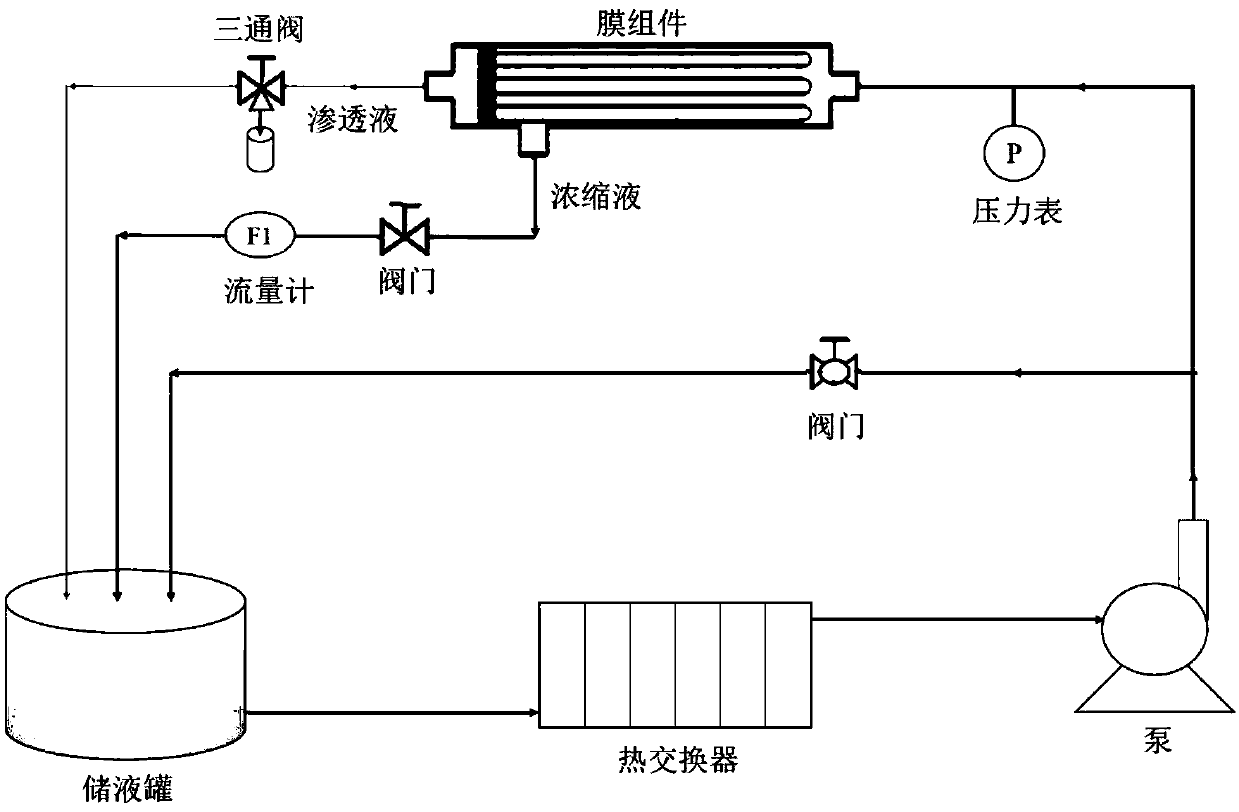

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the preferred novel Janus polymer hollow fiber membrane of the present invention, comprises the steps:

[0050] Step 1: First, perform ultrasonic cleaning on the polymer hollow fiber membrane material (ultrasonic power is 100W-360W), and then use bisphenol A type epoxy resin and amine curing agent to cure and seal its two ends.

[0051] Step 2: prepare a certain concentration of benzoyl peroxide initiator solution (the concentration of benzoyl peroxide in acetone is 3wt%-11wt%), and soak the end-capped membrane silk in step 1; after 2h-6h, The membrane filaments are taken out, and the membrane material loaded with the initiator is obtained after the solvent is completely volatilized.

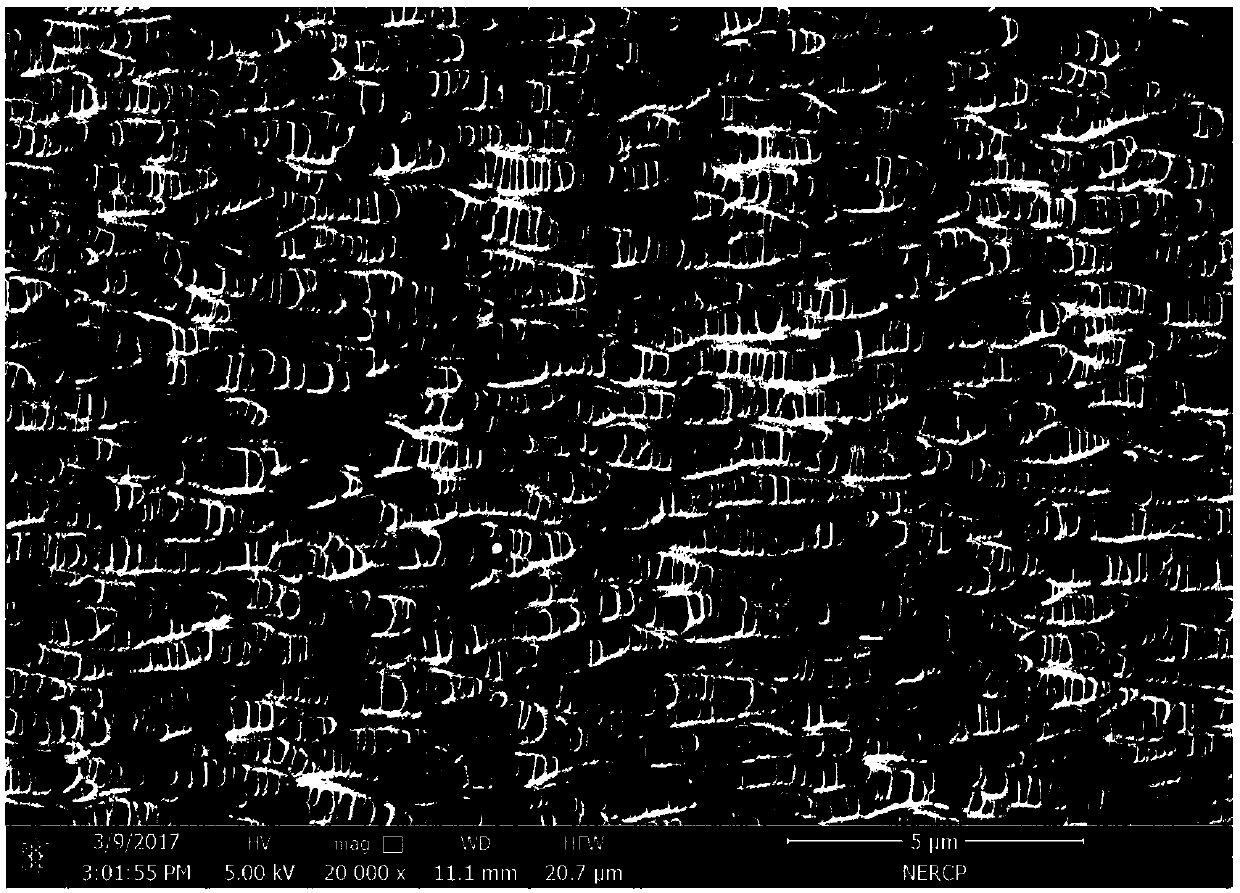

[0052] Step 3: Mix the vinyl monomer with maleic anhydride, deionized water and organic solvent, transfer the mixed solution to an ultrasonic reaction instrument, heat it to a certain temperature and pass nitrogen gas, and finally put the membrane loaded with the...

Embodiment 1

[0080] The preparation method of the novel Janus polymer hollow fiber membrane in this embodiment is realized according to the following steps:

[0081] Step 1. First, ultrasonically clean the polypropylene hollow fiber membrane material with an ultrasonic power of 100W for 1 hour, and then seal both ends of the polypropylene hollow fiber membrane with bisphenol A epoxy resin and amine curing agent.

[0082] Step 2: preparing a benzoylacetone peroxide solution with a concentration of 3 wt%, soaking the capped membrane filaments in step 1; taking out the membrane filaments after 6 hours, and obtaining the membrane material loaded with the initiator after the solvent is completely volatilized.

[0083] Step 3. Mix 2.7g of styrene, 5.06g of maleic anhydride, 14.73g of deionized water and 132.59g of acetone, and transfer the mixed solution to an ultrasonic reaction instrument, heat it to 60°C and pass in nitrogen gas, and finally put the load The membrane silk with the initiator w...

Embodiment 2

[0088] The preparation method of the novel Janus polymer hollow fiber membrane in this embodiment is realized according to the following steps:

[0089] Step 1. First, ultrasonically clean the polypropylene hollow fiber membrane material with an ultrasonic power of 250W for 1 hour, and then seal both ends of the polypropylene hollow fiber membrane with bisphenol A epoxy resin and amine curing agent.

[0090] Step 2: preparing a benzoylacetone peroxide solution with a concentration of 5 wt%, soaking the capped membrane filaments in step 1; taking out the membrane filaments after 6 hours, and obtaining the membrane material loaded with the initiator after the solvent is completely volatilized.

[0091] Step 3: Mix 4.77g of styrene, 2.99g of maleic anhydride, 29.46g of deionized water and 117.86g of acetone, transfer the mixed solution to an ultrasonic reaction instrument, heat it to 65°C and pass in nitrogen gas, and finally put the load The membrane silk with the initiator was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com