Object and method for simulating and detecting pressure in penetration fusion welding small hole

A deep penetration welding and internal pressure technology, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve the problems that need to be deepened, the correctness of simulation and calculation results cannot be verified by experimental means, and there is no internal pressure in the hole. problems, to achieve the effect of deepening understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

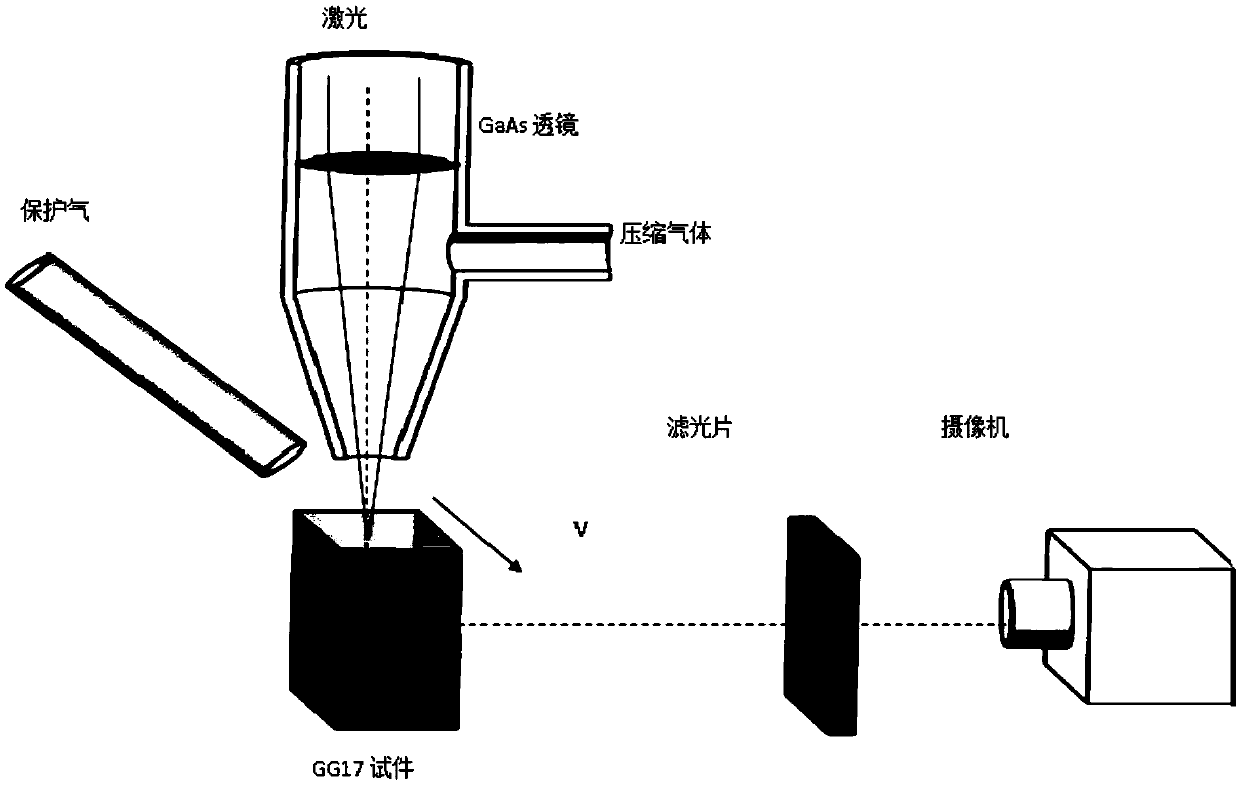

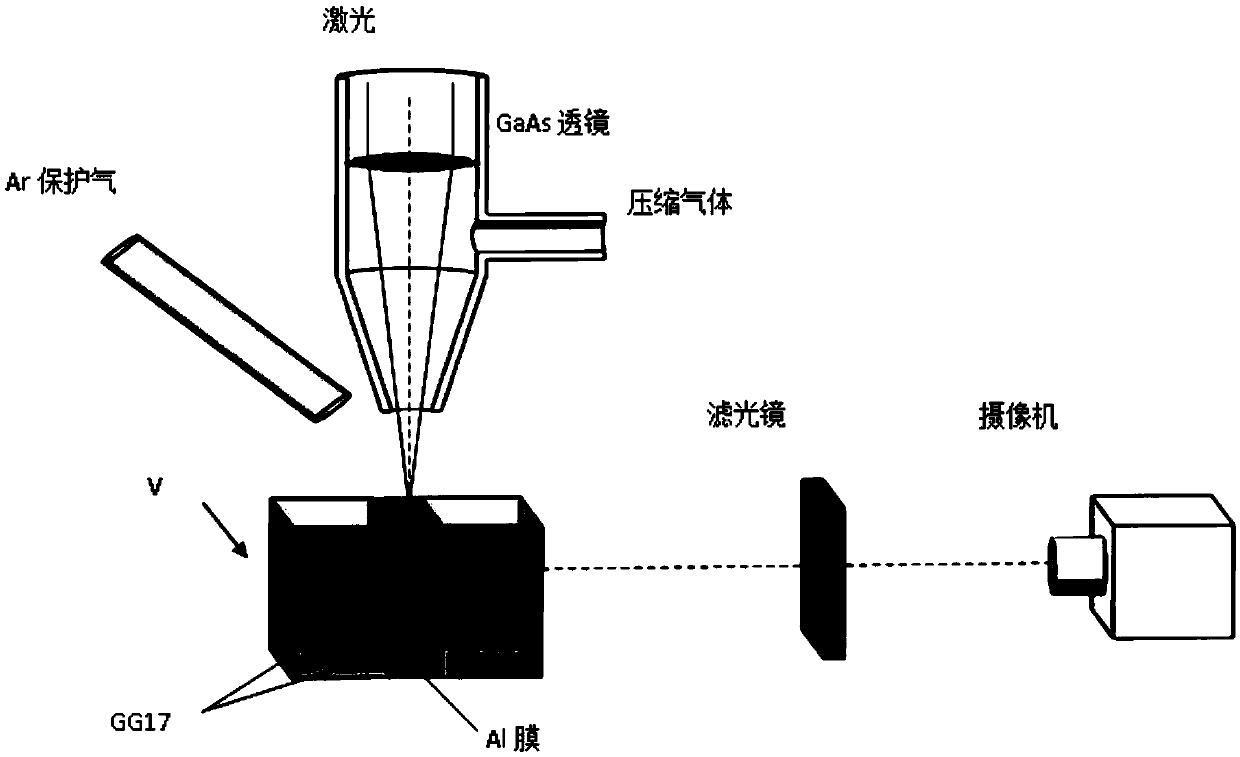

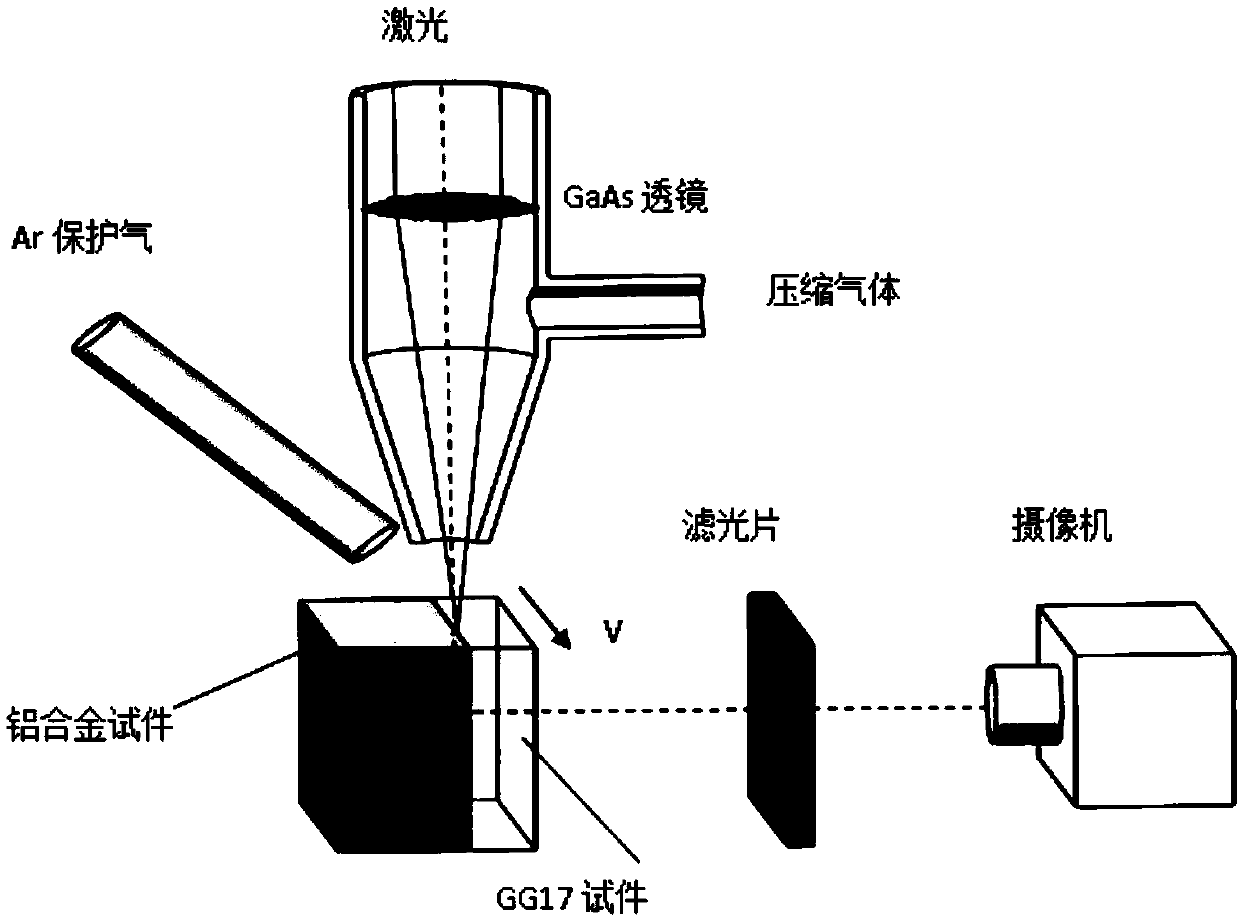

[0053] This embodiment provides as Image 6 The omnidirectional direct observation device for the shape of the small hole in the deep penetration welding of the metal material, and the use of such as Image 6 The device shown is a technical solution for directly observing the cross-sectional contour shape of small holes at different depths in layers.

[0054]The all-round direct observation device for the shape of small holes in deep penetration welding of metal materials includes a welding head, a composite test piece located under the welding head, and an image capturing component for observing the shape of small holes; the welding head is capable of using laser or electronic The welding head of the beam; the composite test piece includes the upper metal part 4 and the lower GG17 part 5, and the top surface of the whole composite test piece, that is, the top surface of the metal part, is a plane, and the bottom surface of the metal part and the top surface of the GG17 part ...

Embodiment 2

[0071] This embodiment provides as Figure 5 The object and device for simulating and detecting the pressure in the small hole of deep penetration welding, and the method for simulating and detecting the pressure in the small hole of deep penetration welding.

[0072] The high-pressure gas is sprayed onto the surface of the experimental liquid 22 along the side wall of the liquid container 24 through the high-pressure gas spray head 15 to form a simulated small hole 17 in the liquid. The high-pressure gas passes through the spray head 15 and the liquid container 24 has relative motion. The gas pressure is detected by the pressure gauge 16. The high-speed camera, that is, the first camera 18, shoots the appearance of the longitudinal symmetrical plane of the simulated small hole through the transparent side wall of the liquid container 24. The high-speed camera, that is, the second camera 20, shoots the liquid through the support 21. Simulated pinhole topography on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com