Method for deep treatment of nitrate nitrogen in wastewater based on electrochemistry and resin combining technology

A combined process and advanced treatment technology, applied in the field of nitrate nitrogen, can solve the problems of filter membrane pollution, high power consumption, low ozone utilization rate, etc., and achieve the effects of simple operation process, good regeneration performance and stable operation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

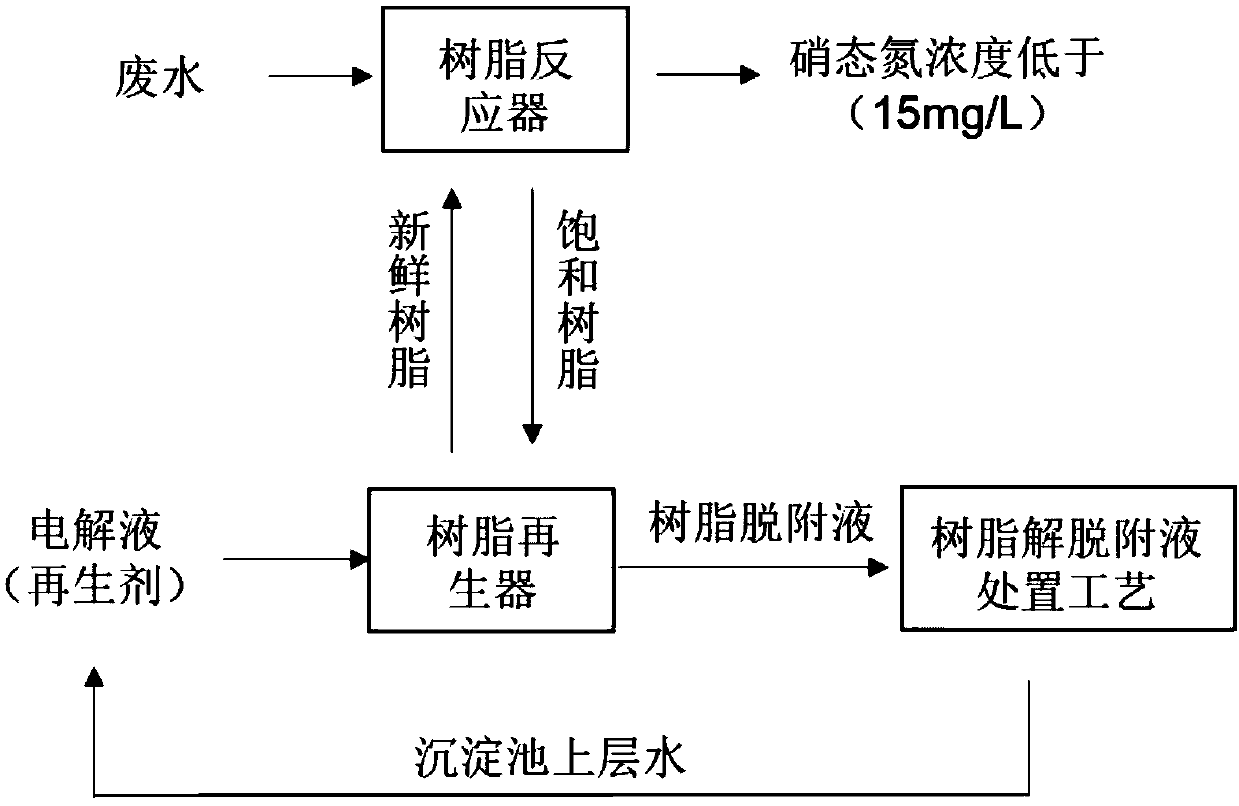

[0028] like figure 1 As shown, the method for advanced treatment of nitrate nitrogen in waste water based on electrochemical and resin combination process provided by the present invention comprises the following steps in sequence:

[0029] A. Resin adsorption process, pass the wastewater to be treated with a nitrate nitrogen concentration of 20mg / L through a 10ml resin column, adjust the influent flow rate to 6BV / h, and stop the adsorption when the adsorption reaches the breakthrough point;

[0030] B. Saturated resin regeneration process, that is, the resin adsorbed and saturated in the resin reactor is discharged into the resin regenerator, and 100ml of 12% sodium chloride solution is used as the regenerant, and the volume ratio of the regenerant to the resin is 10:1 to obtain 10ml Fresh resin and 100ml desorption solution, the concentration of nitrate nitrogen in the desorption solution is 947.98mg / L;

[0031] C, desorption solution treatment process, the 100ml desorption...

Embodiment 2

[0036] The method for advanced treatment of nitrate nitrogen in wastewater based on electrochemical and resin combination process provided by the present invention comprises the following steps in sequence:

[0037] A. Resin adsorption process, pass the wastewater to be treated with a nitrate nitrogen concentration of 45mg / L through a 10ml resin column, adjust the influent flow rate to 6BV / h, and stop the adsorption when the adsorption reaches the breakthrough point;

[0038]B, saturated resin regeneration process, is about to discharge the saturated resin in the resin reactor into the resin regenerator, use 12% sodium chloride solution of 100ml as regenerant, the volume ratio of regenerant and resin is 10:1, obtain 10ml of fresh resin and 100ml of desorption solution, the concentration of nitrate nitrogen in the desorption solution is 913.94mg / L;

[0039] C, desorption solution treatment process, the 100ml desorption solution obtained in step B is about to be electrolyzed, an...

Embodiment 3

[0044] The method for advanced treatment of nitrate nitrogen in wastewater based on electrochemical and resin combination process provided by the present invention comprises the following steps in sequence:

[0045] A. Resin adsorption process, pass the wastewater to be treated with a nitrate nitrogen concentration of 80mg / L through a 10ml resin column, adjust the influent flow rate to 6BV / h, and stop the adsorption when the adsorption reaches the breakthrough point;

[0046] B. Saturated resin regeneration process, that is, the resin adsorbed and saturated in the resin reactor is discharged into the resin regenerator, and 100ml of 12% sodium chloride solution is used as the regenerant, and the volume ratio of the regenerant to the resin is 10:1 to obtain 10ml Fresh resin and 100ml desorption solution, the concentration of nitrate nitrogen in the desorption solution is 950.11mg / L;

[0047] C, desorption solution treatment process, the 100ml desorption solution obtained in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com