A kind of modified rubber asphalt and preparation method thereof

A technology for modifying rubber and asphalt, used in building components, building insulation materials, buildings, etc., can solve the problems of high viscosity of rubber asphalt, poor high temperature performance, reduced high temperature performance, etc., to achieve good adhesion and enhanced compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

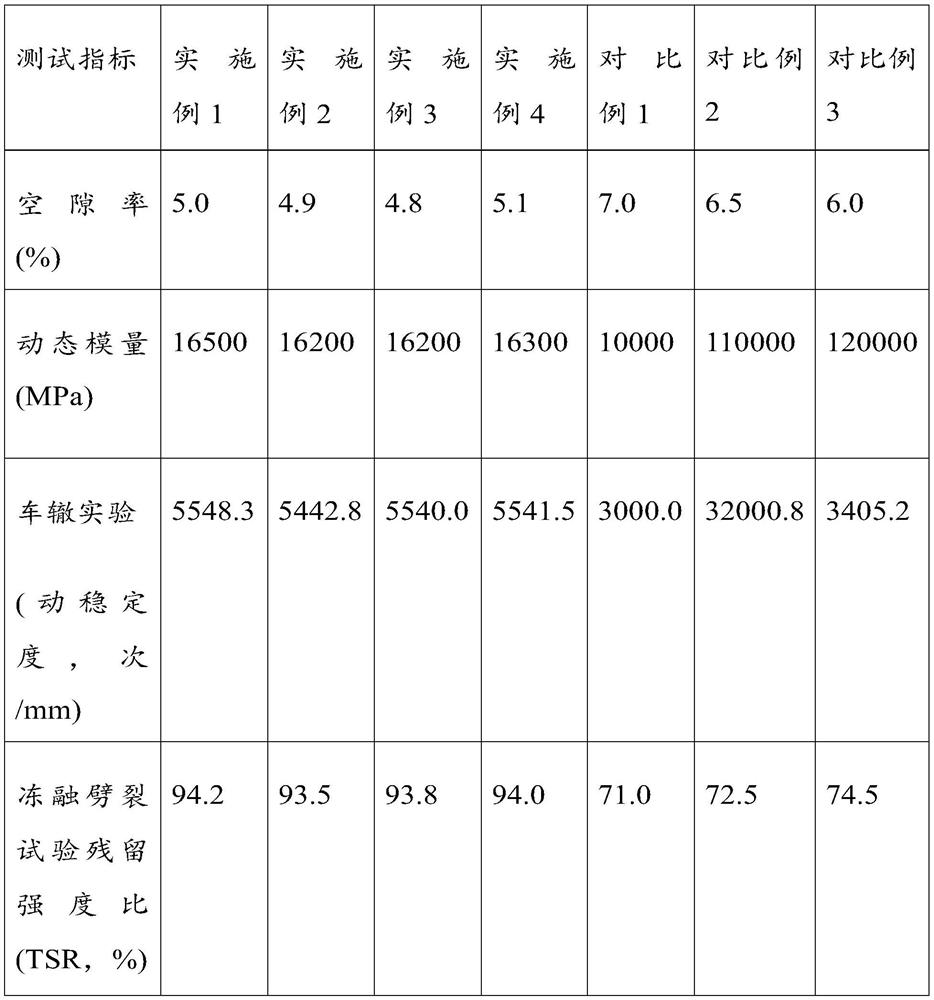

Examples

preparation example Construction

[0027] In the preparation process of the modified graphene oxide in the embodiment of the present invention, the reaction raw material uses expanded graphite oxide as a precursor instead of directly using graphite oxide as a precursor. There are two main advantages: one is that the expanded graphite oxide is relatively fluffy and has a large specific surface area. After expansion, there are still oxygen-containing functional groups on it, providing binding sites for adsorption, and a reduction reaction occurs at room temperature. Due to its large surface area, the content of modifiers on the support is increased. The second is that instead of adding auxiliary dispersants such as isopropanol and polyvinylpyrrolidone during the preparation process as in the traditional preparation method, the reducing agent is directly used, so that the prepared material has no other impurities, which is relatively "clean" and the reaction time The addition of expanded graphite oxide is mixed w...

Embodiment 1

[0031] A modified rubber asphalt, comprising the following raw materials in parts by weight: 100 parts of asphalt matrix, 20-40 parts of rubber powder, 10-25 parts of modified graphene oxide, 5-15 parts of resin, 5-15 parts of fiber and stable 5-15 doses.

[0032] The preparation method of above-mentioned modified rubber asphalt:

[0033] Grind graphite oxide into powder and calcinate it in a muffle furnace at 800°C to obtain expanded graphite oxide. Add expanded graphene oxide to ethanol under the condition of a water bath at 50°C, and ultrasonically disperse it; then add and expand graphene oxide The mass ratio of oleic acid is 1:1. After reacting for 1.5 minutes, cool to room temperature, wash with absolute ethanol to remove unreacted oleic acid, and then vacuum freeze-dry to obtain oleic acid-modified graphene oxide.

[0034] Add rubber powder, oleic acid-modified graphene oxide, resin and fiber to the asphalt matrix, heat and stir at 200°C for 20 minutes; then add 5-15 p...

Embodiment 2

[0036] A modified rubber asphalt, comprising the following raw materials in parts by weight: 100 parts of asphalt matrix, 25-35 parts of rubber powder, 10-20 parts of modified graphene oxide, 5-12 parts of resin, 5-12 parts of fiber and stable 5-12 doses.

[0037] The preparation method of above-mentioned modified rubber asphalt:

[0038]Grind graphite oxide into powder and calcinate it in a muffle furnace at 1000°C to obtain expanded graphite oxide. Add expanded graphene oxide to ethanol in a water bath at 70°C and ultrasonically disperse it; then add expanded graphene oxide The mass ratio of maleic anhydride is 1:100. After reacting for 1.5, cool to room temperature and wash with absolute ethanol to remove unreacted maleic anhydride, and then vacuum freeze-dry to obtain maleic anhydride-modified graphene oxide .

[0039] Add rubber powder, maleic anhydride-modified graphene oxide, resin and fiber into the asphalt matrix, heat and stir at 200°C for 20 minutes; then add 5-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com