Cellulose diacetate pulp and preparing method thereof

A technology of cellulose diacetate and pulp, which is applied in the fields of cellulose pulp post-treatment, fiber raw material treatment, pulp property modification, etc., which can solve problems such as unfavorable actual production, achieve low cost, uniform structure, and easy control of moisture content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

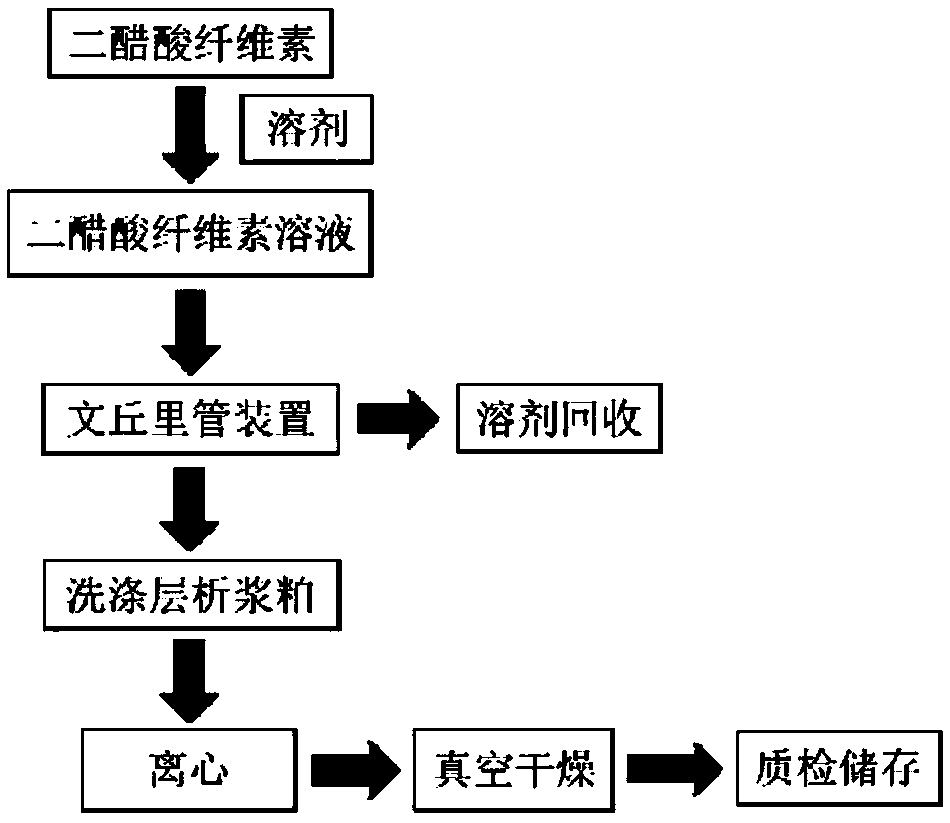

[0041] This embodiment provides a kind of preparation method of cellulose diacetate pulp, and specific preparation process is as follows figure 1 Shown:

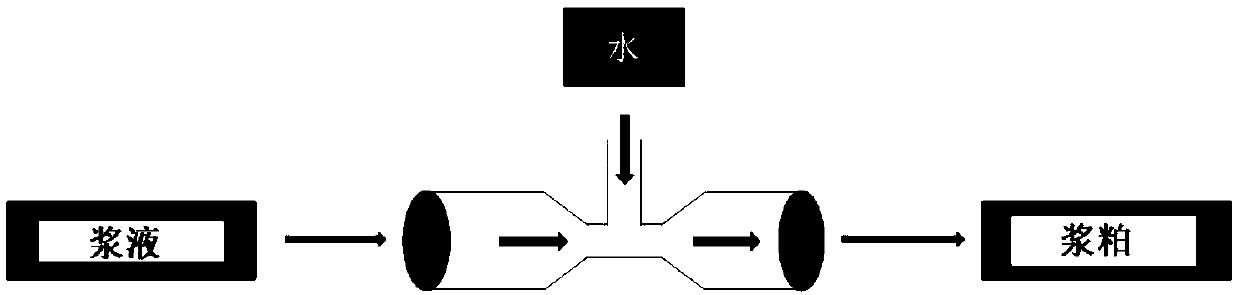

[0042] (1) Completely dissolve cellulose diacetate with a relative molecular mass of 250,000 in acetone to prepare a uniform cellulose diacetate slurry with a concentration of 10 wt%. The temperature of the cellulose diacetate slurry is 60°C, and the delivery pressure is 5MPa Next, inject the slurry into the acetone coagulation bath after passing through the Venturi tube device to obtain the initial cellulose diacetate pulp; the water content in the coagulation bath is 80%;

[0043] (2) The initial cellulose diacetate pulp is washed repeatedly with a large amount of water to obtain the cellulose diacetate pulp, and the cellulose diacetate can be further washed, centrifuged and vacuum-dried to obtain a finished product. The obtained cellulose diacetate pulp has a large specific surface area and a uniform structure.

[0044]...

Embodiment 2

[0046] This embodiment provides a kind of preparation method of cellulose diacetate pulp

[0047] (1) The cellulose diacetate that relative molecular weight is 400000 is dissolved completely in dimethylacetamide, is mixed with concentration and is the cellulose diacetate slurry that is uniform of 7wt%, and the temperature of cellulose diacetate slurry is 50 ℃, in Under the delivery pressure of 5MPa, inject the slurry into dimethylacetamide after passing through the Venturi device to obtain the initial cellulose diacetate pulp; the water content in the coagulation bath is 90%;

[0048] (2) The initial cellulose diacetate pulp is washed repeatedly with a large amount of water to obtain the cellulose diacetate pulp, and the cellulose diacetate can be further washed, centrifuged and vacuum-dried to obtain a finished product.

[0049] Among them, the solvent can be recovered in the Venturi tube device.

Embodiment 3

[0051] This embodiment provides a kind of preparation method of cellulose diacetate pulp

[0052] (1) Completely dissolve cellulose diacetate with a relative molecular mass of 700,000 in a mixed solvent of dimethylacetamide and dimethyl sulfoxide (the mass ratio of the two is 1:1), and prepare a uniform concentration of 5 wt%. The cellulose diacetate slurry, the temperature of the cellulose diacetate slurry is 65 ℃, and under the delivery pressure of 0.1MPa, the slurry is injected into the coagulation bath of dimethylacetamide and dimethyl sulfoxide after passing through the Venturi tube device, The initial cellulose diacetate pulp is obtained; the water content in the coagulation bath is 95%;

[0053] (2) The initial cellulose diacetate pulp is washed repeatedly with a large amount of water to obtain the cellulose diacetate pulp, and the cellulose diacetate can be further washed, centrifuged and vacuum-dried to obtain a finished product.

[0054] Among them, the solvent can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com